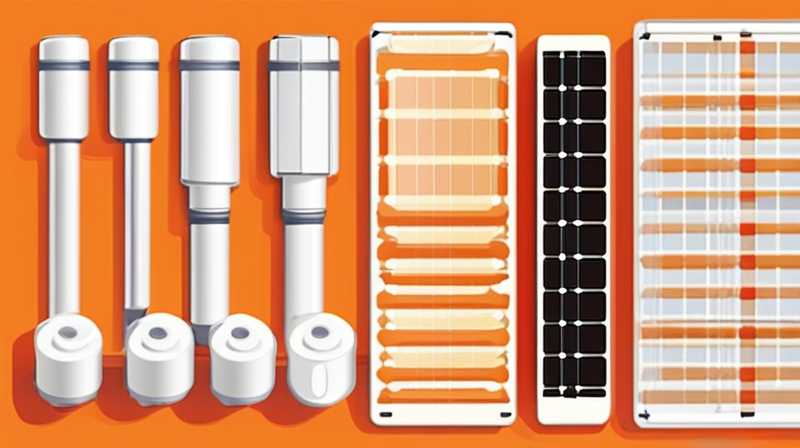

Sealing a solar panel tube is a crucial aspect of maintaining optimal efficiency and longevity of solar energy systems. 1. Ensure all components are clean and dry, 2. Choose an appropriate sealing material, 3. Apply the sealant evenly, 4. Allow adequate curing time. The success of this sealing process substantially impacts the system’s overall performance and resistance to potential environmental damages.

1. IMPORTANCE OF SEALING SOLAR PANEL TUBES

The sealing of solar panel tubes cannot be overstated, as it plays a pivotal role in safeguarding the internal mechanisms from environmental challenges. When tubes are not adequately sealed, moisture and debris can infiltrate the system, leading to diminished efficiency and possible catastrophic failure. Understanding the necessity for sealing involves recognizing the challenges posed by various weather conditions, which can alter the structural integrity of solar components.

A properly sealed tube serves multiple functions. Maintaining thermal efficiency is perhaps the most critical aspect; a well-sealed tube ensures that the heat generated inside does not dissipate unnecessarily. By trapping warmth within the tube, the overall performance of the solar panels is enhanced, maximizing energy capture throughout the day. Therefore, ensuring the seal is optimal becomes an indispensable component in solar panel maintenance.

Moreover, tubes that are compromised can lead to decreased solar energy conversion rates. If water or foreign materials infiltrate, they can potentially interfere with the operational elements that convert sunlight into usable energy. By sealing these tubes properly, owners can not only protect their investment but also enhance their system’s overall lifespan.

2. SELECTING THE APPROPRIATE SEALING MATERIAL

Choosing a sealant for solar panel tubes requires an informed approach, as various materials possess different properties and effectiveness levels. Silicone, epoxy, and polyurethane are commonly employed sealants in solar applications. Each material offers specific advantages and disadvantages, suggesting that careful consideration must be made based on the unique operating conditions and requirements of the solar installation.

Silicone sealants are often favored due to their flexibility and resistance to weathering. They adhere well to a variety of surfaces and maintain their sealing capabilities over time despite temperature fluctuations. This adaptability can be especially beneficial in environments with extreme weather conditions. However, silicone may not bond as effectively to certain plastics, which could be a significant factor depending on the composition of the solar panel tubes used.

On the other hand, epoxy sealants are known for their superior bond strength and durability. Suitable for more rigorous applications, epoxy can withstand heavy loads and harsh chemicals, making it an excellent choice for installations expected to face severe conditions. However, epoxy typically comes with a longer curing time and rigid properties that may not be ideal in scenarios of fluctuation in thermal expansion.

Polyurethane sealants combine the best features of silicone and epoxy by providing elasticity while offering strong adhesion. These sealants resist environmental degradation due to UV exposure and may provide the most balanced option for a wide range of applications. Considering the specific environment and tube material is essential in selecting the right type of sealant to optimize performance and longevity.

3. PREPARING THE SURFACE FOR SEALING

Preparation of the surface is arguably one of the most crucial steps in the sealing process. Before any sealant is applied, ensuring that the surfaces are thoroughly clean and devoid of dirt, grease, or moisture is paramount. Such contaminants can greatly impede the adhesive properties of the sealant, leading to inefficient seals that may fail prematurely.

To begin with, using a suitable cleaner solution to wipe down the surfaces is essential. This may involve a combination of soap and water, followed by a rinse with clean water. After cleaning, an appropriate drying method should be deployed; air drying can assist in achieving a clean surface, but achieving complete dryness is vital. In some cases, using compressed air can accelerate the process and ensure that no residual water affects the sealing material.

Once the cleansing is completed, a meticulous inspection of the surfaces for any cracks or imperfections should be conducted. Identifying these issues beforehand allows for prior repairs that can further enhance the integrity of the seal. If any damage is detected, it is advisable to correct it using relevant repair materials before proceeding with the sealing process. Such proactive steps will guarantee that the seal achieves a strong bond, enhancing the overall longevity of the installed solar panels.

4. APPLICATION TECHNIQUE FOR SEALANT

Applying the selected sealant effectively demands attention to detail and methodical execution. The first step involves using appropriate tools for ideal application. For many sealants, utilizing a caulking gun is recommended for even distribution, allowing the material to be delivered in a controlled manner. Additionally, tools such as spatulas or brushes may assist in spreading the sealant uniformly across the surfaces.

When beginning the application, it is advisable to work in manageable sections rather than attempting to cover large areas all at once. This approach ensures that the sealant remains workable, leading to a more effective bond. As the sealant is applied, maintaining consistent pressure is crucial, ensuring that the material is evenly distributed without gaps that could compromise the seal’s integrity.

Moreover, the specific method of application may vary based on the type of sealant being used. For instance, silicone seals require a smooth finish to prevent trapping air pockets, while epoxy might necessitate a thicker layer to ensure durability. Following the manufacturer’s instructions in terms of thickness and application methods is essential to realize the full benefits of the selected sealant.

Allowing the sealant adequate curing time post-application is the final vital consideration. Curing is the process by which the sealant transitions from a liquid state into a solid form, establishing its adhesive properties. A neglect of this step may result in failure of the seal, ultimately altering the system’s performance negatively. Depending on the chosen material, curing times may vary, but completing this process is imperative before resuming operations on the solar panel system.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE BEST SEALANT FOR SOLAR PANEL TUBES?

The optimal choice of sealant for solar panel tubes can vary significantly based on the specific application. Silicone, epoxy, and polyurethane are frequently utilized options in this context. Silicone offers excellent flexibility and longevity, making it suitable for a variety of conditions, particularly where elasticity is necessary. Epoxy provides robust adhesion and durability, recommended for installations subject to harsh environmental conditions or significant stress. Meanwhile, polyurethane serves as a middle ground, combining features that allow for effective sealing under a range of circumstances. To select the best option, consider the material of the solar panel tubes, the expected environmental stressors, and the desired longevity.

HOW DO I KNOW IF MY SOLAR PANEL TUBES NEED SEALING?

Identifying the need for sealing solar panel tubes may involve inspecting for visible signs of damage or deterioration. Look for indications such as cracks, leaks, or discoloration around the junction of the tubes. Moisture accumulation around the tubes or within the panel can also signal the need for resealing. Regular maintenance checks, using both visual and manual inspections, can detect wear over time. Additionally, fluctuations in solar panel performance—a sudden drop in efficiency—could indicate a compromised tube seal. It’s wise to perform these checks periodically, particularly after extreme weather events, to ensure your system operates at peak performance.

CAN I SEAL SOLAR PANEL TUBES MYSELF?

Sealing solar panel tubes can indeed be accomplished by an informed individual with the right tools and materials. However, understanding the process and intricacies involved is crucial to success. Familiarity with the different types of sealants, surface preparation requirements, and application methodologies are essential components. Following manufacturer guidelines and best practices ensures a reliable seal is achieved. While it is feasible to undertake this task independently, consulting a professional for the initial sealing can provide valuable insights and proper execution. Such expertise can enhance the overall quality of work and ultimately improve the longevity and efficiency of the solar panel system.

The process of ensuring optimal sealing of solar panel tubes is multifaceted and requires diligence and understanding. The choice of sealant is critical, as different materials offer varying degrees of flexibility, durability, and resistance to environmental challenges. Preparing the surfaces is equally important, necessitating meticulous cleaning and inspection to prevent premature failure. The application of the chosen sealant must adhere to best practices, with attention given to curing time to solidify the bond created.

Engaging in regular inspections and maintenance can enhance the reliability of solar systems. Given the importance of these efforts in maximizing energy efficiency and extending lifespans of installations, taking the necessary steps to seal tubes effectively cultivates continued investment in renewable energy solutions. As such, embracing robust sealing techniques and practices not only protects the physical components of solar installations but also fortifies the push towards a more sustainable energy future. Ultimately, investing time and resources into quality sealing measures guarantees long-term success, flexibility, and resilience of solar energy systems that cater to the demands of an ever-changing environment.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-seal-the-solar-panel-tube/