To effectively seal solar glass tubes and maximize their durability and efficiency, adhere to the following critical practices: 1. Use high-quality sealants, 2. Ensure clean surfaces, 3. Implement appropriate curing times, 4. Maintain consistent temperature during sealing. Each step holds significant importance in maintaining the integrity of solar glass tubes that serve in applications like solar water heating or photovoltaic systems.

When installing a solar thermal system, the sealing of glass tubes is paramount to prevent moisture ingress, enhance thermal performance, and ensure longevity. To achieve these objectives, professionals must select the right materials, techniques, and practices.

1. IMPORTANCE OF SEALING SOLAR GLASS TUBES

The sealing of solar glass tubes is a crucial process that contributes significantly to the overall effectiveness of solar energy systems. Sealing not only protects the internal components of the tubes from external environmental factors but also enhances energy efficiency. When solar tubes are properly sealed, they resist moisture intrusion, dust contamination, and physical wear. The integrity of these systems is maintained, ensuring they operate at optimal levels throughout their lifespan.

Another consideration in sealing solar glass tubes involves compatibility with other system components. Choosing the right sealant that aligns with the materials used in the solar system adds another layer of protection and efficiency. A common issue arises when inappropriate sealants are employed, which may degrade over time and adversely affect functionality. Consequently, selecting a suitable sealant is crucial in preserving the system’s viability and performance.

2. MATERIALS NEEDED FOR SEALING

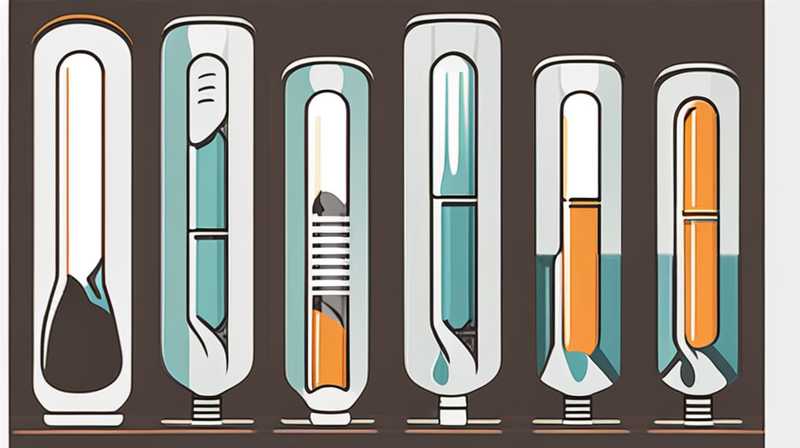

When embarking on the process of sealing solar glass tubes, it’s essential to gather the necessary materials. The primary sealant options include silicone-based adhesives, polyurethane sealants, and butyl rubber. Each has its unique properties, advantages, and suitable applications. Silicone sealants, for instance, are flexible and offer excellent adhesion, making them ideal for areas that may experience thermal expansion or contraction. Conversely, polyurethane provides superior durability and is more resistant to environmental factors.

In addition to sealants, choosing the right tools aids in achieving professional-grade results. Basic tools required include a caulking gun for easy application, wipes for surface cleaning, and a utility knife for trimming. Having these materials and tools on hand before starting the project ensures a smooth workflow and contributes to the overall success of the sealing process, minimizing the potential for mistakes that could lead to inefficiencies or system failures.

3. PREPARATION OF SURFACES

Prior to applying sealants, preparation of the surfaces involved is crucial. Surfaces should be thoroughly cleaned to remove dust, grease, or debris, which could hinder the adhesion of the sealant. Use appropriate cleaning agents and ensure that the surfaces are dry before proceeding. This step is vital in establishing a strong bond between the sealant and the glass tubes, preventing any weaknesses that may develop over time.

A detailed inspection of the surfaces should also take place. Look for any existing cracks, chips, or defects that could compromise the integrity of the seal. Address any such issues before applying sealants; this may involve repairing or replacing parts of the tube. Investing time in preparation greatly enhances the effectiveness of the sealing process, ultimately leading to improved performance and longevity of the solar glass tubes.

4. TECHNIQUES FOR SEALING

Implementing effective sealing techniques plays an essential role in achieving optimal results. One common method involves applying the sealant in a continuous line without interruptions. This ensures consistent coverage and minimizes the likelihood of gaps that could lead to moisture intrusion. Maintaining a steady hand while applying the sealant allows for uniform distribution, which significantly aids adhesion.

Another recommendation is to practice layering methods. For larger areas, first apply a base layer of sealant. After it dries fully, a second layer can be applied for added strength. This two-step process creates a robust seal that is more resistant to external pressure and can withstand environmental changes. In some instances, using a finishing tool to smooth out the applied sealant helps achieve a professional finish and strengthens the bond with the surface.

5. ALLOWING FOR CURE TIME

After applying the sealant, allowing adequate cure time becomes essential. This period enables the sealant to bond effectively with the glass, providing maximum protection. Each sealant type has its own recommended curing time, so be sure to follow the manufacturer’s guidelines. For example, silicone may require 24 hours to set, while polyurethane may take longer depending on temperature and humidity conditions.

Curing should occur in a controlled environment, where temperatures remain steady within the recommended range. Excessive fluctuations in temperature can undermine the effectiveness of the seal. Moreover, care should be taken to avoid any stress on the newly sealed joint during the curing phase. This approach ensures that the seal maintains its integrity, supporting the overall efficiency and performance of the solar glass tubes.

6. MAINTAINING THE SEALED SYSTEM

Once the sealing process is complete, ongoing maintenance is vital to ensure the longevity and effectiveness of the solar glass tubes. Regular inspections should be scheduled to monitor the seal’s integrity and identify any signs of damage or wear early. This proactive approach helps prevent moisture intrusion, contributing to the system’s efficiency over time.

In addition to routine inspections, cleaning the exterior of the tubes is beneficial. Maintaining a clear surface not only enhances the appearance but allows more sunlight to penetrate, boosting energy absorption. Use non-abrasive cleaning materials to avoid scratching the glass, which could compromise the seal integrity. Routine care contributes significantly to achieving optimal performance and longevity in a solar energy system.

FREQUENTLY ASKED QUESTIONS

HOW DO I KNOW IF THE SEAL ON MY SOLAR GLASS TUBES IS LEAKING?

To identify potential leaks in solar glass tubes, maintain vigilance with regular inspections. Examine the seals visually for any signs of discoloration, cracking, or separation from the glass. Water stains or condensation inside the tubes also indicate problems. If any unusual moisture accumulation occurs, it may signal that the seal is compromised and repairs or resealing is necessary.

A more thorough method involves performing a pressure test. Create a slight vacuum inside the tubes and see if the pressure holds. If the pressure drops unexpectedly, there could be a breach in the seal. Address any leaks promptly to avoid further complications impacting the system’s efficiency and lifespan, ensuring optimal performance and energy gains.

WHAT TYPES OF SEALANTS WORK BEST FOR SOLAR GLASS TUBES?

Several sealant types suit solar glass tube applications, each with unique properties. Silicone-based sealants are prominent for their flexibility and strong adhesion, making them suitable for thermal expansion and contraction. Alternatively, polyurethane sealants provide enhanced durability and environmental resistance, ideal for extreme conditions.

When selecting a sealant, ensure compatibility with the glass and the system as a whole. Butyl rubber sealants are another excellent option, demonstrating strong adhesion and flexibility while remaining unaffected by moisture. Ultimately, careful consideration of environmental conditions and specific application needs will guide the selection of the most effective sealant type.

HOW OFTEN SHOULD I RESEAL MY SOLAR GLASS TUBES?

The frequency of resealing solar glass tubes hinges on multiple factors including system usage, environmental conditions, and sealant quality. On average, it is advisable to inspect seals annually and perform resealing every five to ten years, depending on wear. Factors such as exposure to UV radiation, temperature fluctuations, and moisture can accelerate wear, necessitating more frequent inspections and resealing.

Additional signs that indicate the need for resealing include visible cracks, gaps, or an increase in condensation within the tubes. Performing thorough inspections regularly helps catch issues early, maximizing the lifespan of solar tubes and ensuring optimal performance. Establishing a preventive maintenance routine enhances overall efficiency and energy production while safeguarding the investment in solar technology.

The sealing of solar glass tubes stands as a vital aspect that significantly influences solar energy systems’ performance and longevity. A multifaceted approach is essential, beginning with selecting high-quality materials suited for the specific application. One must pay meticulous attention to preparation, surface cleaning, and application techniques, as these processes lay the foundation for a robust seal. Allowing curing time and implementing ongoing maintenance adds layers of assurance to the effectiveness of the seal and the system. Regular inspections and addressing potential issues proactively can prevent costly repairs and ensure optimal efficiency. In an industry where efficiency translates into cost savings and improved energy production, prioritizing this fundamental process cannot be overemphasized. Thus, investing adequate time and resources into correctly sealing solar glass tubes paves the way for achieving sustainable energy goals while extending the system’s lifespan through continued performance.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-seal-solar-glass-tubes/