Routing wires inside solar panels is a crucial aspect for optimizing efficiency and safety. 1. Correct wire placement facilitates efficient energy transfer, 2. Enhances the aesthetic appeal of solar installations, 3. Prevents potential damage from weather elements, and 4. Reduces the risk of electrical hazards. Delving deeper into prevention of potential damage, maintaining organized and secure wiring can significantly lower the chances of shorts and other electrical failures that can compromise the overall system’s performance. When wiring is securely fastened and arranged strategically within the panel, this ensures not only longevity in terms of equipment but also establishes a safer environment for surrounding installations.

1. IMPORTANCE OF PROPER WIRING IN SOLAR PANELS

Effective wiring plays a pivotal role in the overall functionality of solar panels. The significance of proper cable routing cannot be overstated. When implemented correctly, it ensures that photovoltaic modules operate at peak performance, which effectively maximizes energy generation. Additionally, a well-structured wiring system minimizes maintenance issues that may arise from disordered or insecure connections. Within a solar panel, wires are responsible for transferring electricity generated from sunlight to an inverter, which transforms that direct current (DC) into alternating current (AC), suitable for household or business use.

Furthermore, the alignment and positioning of wires can affect not only electrical efficiency but also the physical integrity of the panel itself. If wires are laid out haphazardly, they may be prone to wear and tear from physical movement, external forces, and environmental factors. For instance, exposure to moisture or extreme temperature changes could lead to wiring insulation breakdown, ultimately jeopardizing the system. Therefore, a focus on meticulous organization and securing cables is indispensable for both functionality and longevity.

2. MATERIALS REQUIRED FOR INSTALLING SOLAR PANEL WIRING

Understanding the materials involved in wiring solar panels is essential for ensuring durability and efficiency. High-quality materials must be utilized to prevent degradation over time. Most solar panel installations rely on solar-grade wiring, specifically designed to withstand the rigors of outdoor environments. This type of wiring is typically durable, resistant to extreme temperatures, and able to tolerate intense ultraviolet (UV) radiation, which is critical for maintaining electricity conduction.

In addition to wires, other components such as cable connectors, junction boxes, and wire management tools are necessary for a comprehensive installation. Cable connectors serve as an essential link between different wiring sections, facilitating seamless electrical flow. Junction boxes, meanwhile, house connections that protect cables from environmental exposure, thus preventing degradation and short circuits. Wire management tools such as cable ties, clips, and conduits are also critical to maintaining organization through proper securing and routing of wires.

3. TECHNIQUES FOR ROUTING SOLAR PANEL WIRES

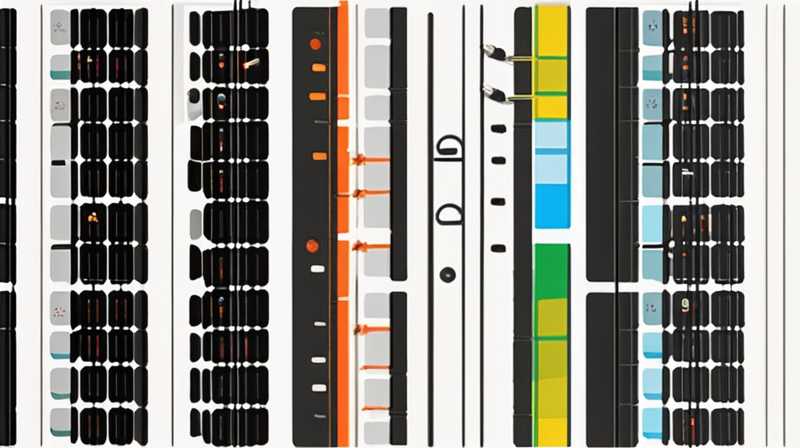

To achieve the best results, a systematic approach to routing wires is required. Several techniques can be employed to optimize wire placement. Firstly, incorporating cable trays or raceways during installation aids in achieving a cleaner appearance and prevents cables from tangling. These systems allow for organized runs of cables, shielding them from environmental factors while maintaining accessibility for maintenance.

Additionally, utilizing strain relief mechanisms enhances the longevity of wire connections. These mechanisms prevent undue stress on wires where they exit a junction box or panel, effectively dispersing force that might otherwise cause wear or damage. Furthermore, incorporating wire insulation sleeves can offer additional protection against abrasion and other potential damages. When executed meticulously, these techniques culminate in a secure, effective wiring system that maximizes both functionality and safety.

4. COMMON ERRORS IN WIRING SOLAR PANELS

Despite the best intentions, mistakes can occur during wiring installations that may lead to inefficiency or safety concerns. Awareness of these common errors is imperative for effective installations. One prevalent mistake is neglecting to use the correct wire gauge, which can lead to voltage drop issues. Using wires that are too thin results in insufficient current transfer and can cause overheating. Conversely, excessively thick wires can be more cumbersome and unnecessarily expensive.

Another mistake is poor connection practices. Loose connections are a high-risk factor for electrical faults, resulting in increased resistance and potential hotspots that may cause fires. Similarly, failing to account for temperature changes can lead to expansion and contraction in the wiring materials, which may compromise connections. By identifying and understanding these pitfalls, solar panel installations can be significantly enhanced, ensuring a safer, more effective energy generation system.

5. REGULATIONS AND STANDARDS FOR SOLAR PANEL WIRING

Adhering to regulations and standards is a fundamental aspect of solar panel wiring. These rules ensure safety and efficiency in installations. Various organizations set forth guidelines dictating parameters such as wire materials, sizes, and installation methods. The National Electric Code (NEC) in the United States, for example, outlines critical specifications that must be followed to ensure heavy-duty insulation, proper grounding, and protection from environmental elements.

Additionally, national and local codes often dictate how installers must ground their systems to prevent electrical surges. Following these standards not only ensures compliance but also enhances safety for both the installation team and the end-users. In clarity and specificity, these regulations serve as protection against disasters that might arise from improper wiring practices. Therefore, staying abreast of these developments is crucial for any professional working in solar technology.

6. MAINTENANCE OF SOLAR PANEL WIRING

Once solar panel wiring is installed, ongoing maintenance is essential for ensuring continuous performance and safety. Regular checks should be incorporated into maintenance routines. This includes inspecting wiring for wear and tear that can accumulate over time, particularly in outdoor environments where exposure to the elements can take its toll. Signs like frayed wires or corroded connections indicate immediate attention is needed.

Cleaning is also a crucial part of maintenance. Dust, dirt, and other debris can obstruct connections and reduce efficiency. The removal of such particles not only keeps systems working optimally but also helps prolong the lifespan of components. Developing a regular inspection and cleaning schedule allows for timely interventions that address small issues before they escalate into larger, more costly problems.

7. TOOLS AND EQUIPMENT FOR INSTALLATION

A well-equipped toolkit can dramatically enhance the efficiency and precision of solar panel wiring installations. Investing in specialized tools is paramount for seamless execution. Essential items include wire strippers, crimping tools, and voltage testers. Each of these tools assists in ensuring that wires are cut and connected properly, reducing the risk of human error that could lead to future operational failures.

In addition to basic tools, utilizing testing equipment can verify proper connections and integrity in wiring before finalizing the installation. This proactive approach is crucial in preempting issues that may lead to energy loss or safety hazards later. By embracing the right equipment, installation becomes more reliable and effective, ultimately exhibiting professionalism and care in solar energy deployments.

8. ADVANCED SYSTEMS FOR WIRING SOLAR PANELS

As technology advances, innovative systems for wiring solar panels continue to emerge. Smart wiring technologies have become popular due to their ability to respond to various conditions optimally. These systems are designed to adjust performance in real-time based on energy demands, environmental factors, and operational conditions. Examples of such technologies include monitoring systems that provide data analytics to operators regarding performance issues, thereby facilitating timely interventions.

Furthermore, improved wire management systems incorporate sensors and automation to decrease manual labor and enhance efficiency. Automated systems can streamline wiring installations significantly by managing wire routes and placement through software, thus allowing for creative, space-efficient configurations. This is a major advancement in the solar industry, making installations more convenient and adaptable to diverse situations.

FAQs

WHAT ARE THE COMMON SAFETY PRECAUTIONS WHEN WIRING SOLAR PANELS?

Proper safety measures are crucial when wiring solar panels to prevent electrical hazards. First, always disconnect power sources before beginning any work. This should include turning off circuit breakers and unplugging any connected devices. Utilizing insulated tools and wearing protective gear, such as gloves and safety glasses, can greatly reduce risk during installation. Furthermore, familiarizing oneself with electrical codes and guidelines is essential for ensuring compliance and minimizing hazards.

It’s also advisable to work with a certified professional, particularly for large-scale installations, to guarantee adherence to safety protocols. Regular inspections after installation can help identify potential problems, including loose connections or exposed wiring.** By being proactive about safety precautions, the risk of accidents can be significantly minimized, promoting a safer environment for all involved.**

HOW DOES IMPROPER WIRING AFFECT SOLAR PANEL PERFORMANCE?

Improper wiring can have detrimental effects on solar panel performance. An incorrect wire arrangement can lead to voltage drop, which diminishes the amount of electricity transferred from the solar panels to the inverter. This results in a decrease in energy efficiency and overall power output, potentially impacting the financial return on the solar investment.

Additionally, poor connections can lead to arcing, overheating, and even electrical fires, creating safety hazards for users. Moreover, inadequate wiring practices can lead to system malfunctions, which may require costly repairs or replacements. In light of these factors, it is paramount to ensure all wiring is completed with precision to optimize both the performance and safety of the solar system.

WHAT TYPES OF MATERIALS ARE BEST FOR SOLAR PANEL WIRING?

When considering solar panel wiring, selecting high-quality materials is non-negotiable for maintaining system efficiency and longevity. Solar-grade wire, specifically designed to withstand outdoor conditions, is recommended for installations. This type of wiring is typically constructed from copper or aluminum with specific insulation that can endure extreme temperatures and UV rays while resisting corrosion.

Furthermore, connectors and junction boxes should also possess weatherproof qualities to prevent degradation from moisture and environmental exposure. Utilizing the right materials might incur a higher upfront cost, but the long-term benefits, such as reduced maintenance and improved energy efficiency, will provide better value over time. Ultimately, opting for certified materials ensures your solar panel installation can withstand the challenges posed by various environmental factors.

The significance of routing wires efficiently inside solar panels cannot be overstated as this determines not only the overall performance of the solar installation but also the safety of its operation. From material selection to installation techniques, a comprehensive understanding of the various elements involved can lead to optimal outcomes. It is essential to follow the established regulations and standards to safeguard against potential hazards that can arise from improper wiring.

Regular maintenance is equally critical, as neglecting this can result in performance degradation, increased costs, and safety issues. Furthermore, utilizing advanced tools and equipment, along with an appreciation for contemporary technologies and innovations, can enhance the quality of your solar panel installations. As the solar industry evolves, staying informed and adapting to new methodologies will become increasingly important for both professionals and homeowners seeking sustainability through renewable energy sources. Investing time and resources into perfecting these systems will pay dividends over time and contribute to a more sustainable and environmentally friendly future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-route-the-wires-inside-solar-panels/