To effectively route the solar solenoid valve line, consider the following key points: 1. Understanding the system layout, 2. Choosing appropriate materials and tools, 3. Ensuring proper connections and sealing, 4. Testing for leaks and functionality. A thorough understanding of the system layout is crucial for the successful installation of a solar solenoid valve line. Familiarizing oneself with the configuration and flow requirements of the system will lead to optimized performance and longevity of the entire setup. Each installation is unique, so taking the time to plan out the route properly can prevent future complications and maintenance issues.

1. UNDERSTANDING THE SYSTEM LAYOUT

When embarking upon the task of routing the solar solenoid valve line, an initial step involves grasping the specific configuration of your solar power system. Every component works collaboratively to maximize efficiency and performance. This necessitates a keen observation of the system layout, so one can determine the optimal path for the valve line.

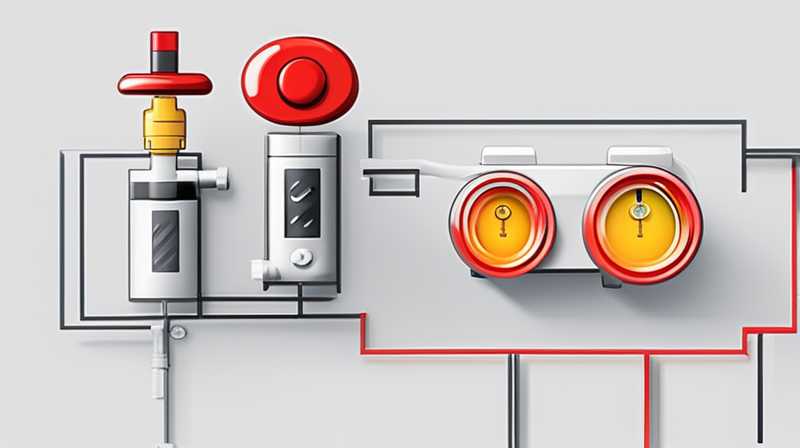

Analyzing the physical location of the solenoid valve in relation to solar panels, water sources, and the controller is critical. Creating a schematic diagram can be beneficial. This visualization provides a clearer picture of where all elements lie in relation to one another. A proper schematic serves not just as a map, but also signals potential areas of concern, such as excessive bends or lengths that could constrict flow.

2. CHOOSING APPROPRIATE MATERIALS AND TOOLS

An equally vital aspect encompasses selecting the right materials and tools to ensure installation is efficient and effective. The material used for the solenoid valve line should offer durability, flexibility, and resistance to environmental factors. Common choices include PVC, polyethylene, or PEX tubing. These materials not only are lightweight but also withstand varying temperature ranges, which is paramount for outdoor applications.

Equipping oneself with the right tools cannot be understated. Essential tools may include a pipe cutter, appropriate fittings, a wrench for tightening connections, and Teflon tape to ensure a leak-proof seal. Each component plays a significant role in the routing process, demanding attention to detail and familiarity with the tools at hand. Proper selection can minimize the likelihood of future issues, such as leaks or bursts, that could compromise the system’s functionality.

3. ENSURING PROPER CONNECTIONS AND SEALING

Once the materials and layout have been established, the focus shifts to ensuring that all connections are made securely. Each joint in the solenoid valve line must be fitted properly to avoid leaks that could deplete the system’s effectiveness. Using appropriate connectors and adapters is paramount, as they influence the integrity of the entire installation.

The application of Teflon tape or pipe sealant aids in enhancing the seal between connections. This is of significant importance at joints and threaded connections, where leaks often manifest. Applying the tape methodically, ensuring it covers the threads without overlapping excessively, can yield a solid seal. It is also imperative to avoid overtightening connections, which may lead to damage or create weak points.

4. TESTING FOR LEAKS AND FUNCTIONALITY

Once the routing process has been completed, diligent testing must follow. This phase is crucial in confirming that the solenoid valve line operates as intended and that all connections remain secure. Pressure testing the system can reveal any leaks, ensuring that the water flow is as expected. This step can save considerable effort in the long run, as a small leak detected early may prevent catastrophic failures later on.

Additionally, testing the valve’s functionality involves activating the solar system to observe the response of the solenoid valve. Ensuring that it opens and closes in relation to solar input is vital. Adjustments should be made if the valve does not respond as expected, as this could indicate an issue with the electrical connections or the solar power mechanism.

FAQs

HOW DO I DETERMINE THE BEST ROUTE FOR MY SOLENOID VALVE LINE?

Determining the best route for the solar solenoid valve line involves a meticulous analysis of the layout of your solar energy system. Begin with observing the positioning of all components involved, such as the solar panels, controller, water source, and the solenoid valve itself. Keep in mind that the route chosen should minimize bends and length while maintaining accessibility for maintenance and inspection. Adequate clearance and avoidance of potential obstacles or hazards is essential. Additionally, evaluating environmental factors such as exposure to elements helps ensure longevity. Gain insights from expert resources or consult professionals for detailed pathways or frameworks that can provide examples of optimized routing solutions.

WHAT TOOLS DO I NEED FOR INSTALLING A SOLENOID VALVE LINE?

When preparing for the installation of a solar solenoid valve line, a suite of essential tools is necessary. Primarily, a pipe cutter will facilitate clean and precise cuts when working with the tubing. A range of fittings and connectors tailored for your specific material are also imperative for creating tight and secure joints. A wrench is handy for tightening connections to the appropriate specifications without overtightening. Teflon tape or a similar pipe sealant ensures that all threaded connections remain leak-proof. Furthermore, consider acquiring additional tools, such as a measuring tape for accurate fitting, to enhance overall installation efficiency.

WHAT ARE COMMON MISTAKES TO AVOID WHEN ROUTING MY SOLENOID VALVE LINE?

Several pitfalls can hinder the effective routing of a solar solenoid valve line. One prominent mistake involves overlooking the importance of planning the layout carefully. A lack of foresight in the routing path can lead to excessive bends and length, impacting flow efficiency. Additionally, failing to choose appropriate materials not resistant to environmental conditions can shorten the lifespan of your system. Neglecting to properly seal connections is another critical error, as it can lead to leaks that waste resources and diminish system performance. Lastly, rushing the testing phase often results in undetected issues that could necessitate extensive repairs in the future.

FINAL THOUGHTS

Routing the solar solenoid valve line necessitates a comprehensive understanding and execution of several key processes designed to optimize efficiency and durability. The establishment of a logical layout forms the foundation upon which all further actions rest. As one navigates the journey of material selection, it becomes essential to consider environmental factors that could influence performance over time. Each tool employed serves as a facilitator, transforming abstract plans into actionable tasks that lead to the successful installation of the valve line. The nuances involved in ensuring that connections are secure and leak-proof cannot be understated, as these aspects significantly influence the system’s overall reliability. Testing serves not merely as a formality but as an imperative phase, confirming that every element fulfills its purpose adequately. By meticulously understanding each phase of routing the solar solenoid valve line, one can assure both the immediate success of the installation and the sustained longevity of the system. The impact of these measures resonates, influencing both efficiency and cost-effectiveness, along with environmental benefits that align with the principles of sustainable living. In light of the emerging demand for renewable energy solutions, mastering these skills becomes increasingly relevant, reflective of a growing recognition of the importance of sustainable practices in today’s world.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-route-the-solar-solenoid-valve-line/