1. The procedure for replacing a solenoid valve in solar energy systems involves several critical steps: proper assessment of the system, careful disconnection of the power supply, meticulous removal of the existing valve, and seamless installation of the new component. 2. Safety precautions are imperative during the entire process due to the involvement of pressurized systems and electrical components. 3. Post-installation testing ensures that the new solenoid valve functions correctly and that the system operates as expected. 4. Regular maintenance of the solenoid valve plays a vital role in prolonging the lifespan of the solar energy system.

UNDERSTANDING SOLENOID VALVES IN SOLAR ENERGY SYSTEMS

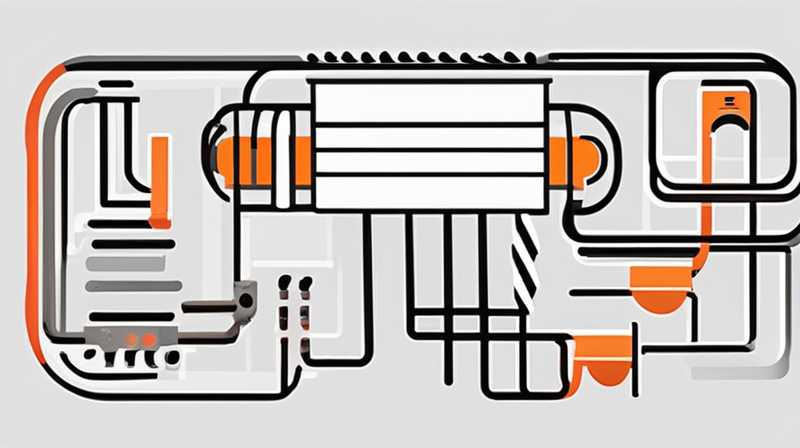

A solenoid valve functions as an electronic device that manages fluid flow within a solar energy system. Utilizing electromagnetic principles, it opens or closes passages depending on electrical signals received from the control system. In solar thermal applications, solenoid valves regulate the flow of heat transfer fluids between collectors and storage tanks, pivotal for maximizing energy efficiency.

This component’s importance cannot be overstated. A malfunctioning solenoid valve can lead to decreased performance, energy wastage, and potential damage to other system parts. Understanding how to effectively replace this part is essential for maintaining optimal functionality.

ASSESSING THE NEED FOR REPLACEMENT

Before embarking on the replacement journey, a thorough assessment of the solenoid valve’s condition should be conducted. Frequently, signs of wear and tear or erratic performance indicate that the valve may no longer function as intended.

Visual inspections are key indicators; leaking fluids, corrosion, or any unusual noises during operation can signal underlying issues. Additionally, the valve’s responsiveness to control signals must be evaluated; a delay or failure to actuate upon receiving an electrical signal highlights impending failure. Once identified, immediate action should be taken to avoid more significant damage down the line.

SAFETY PRECAUTIONS PRIOR TO WORK

Before initiating the replacement process, adherence to strict safety protocols is paramount. It’s crucial to disconnect the solar energy system from the power supply and ensure that all stored energy in capacitors has been safely discharged.

Personal protective equipment (PPE), such as gloves and safety goggles, should be worn throughout the procedure to mitigate risks. Furthermore, understanding the specific schematic of the solar energy system enables effective navigation of the critical components, ensuring safe handling during the replacement operation.

DISCONNECTING THE SOLENOID VALVE

Now that preparations have been made, it is time to disconnect the existing solenoid valve. Begin the process by locating the valve within the system. It is often found in proximity to the pump or heat exchange unit.

Carefully trace the wiring from the control unit to the solenoid valve, ensuring that no wires are damaged during disconnection. Gently remove the wires from their terminals, marking them if necessary to ensure an error-free reconnection later. Additionally, the physical connections of the valve—be it bolted, clamped, or connected via fittings—should be handled with care to prevent damage to surrounding components.

REMOVING THE OLD VALVE

With the solenoid valve disconnected, the focus shifts to its removal. This involves loosening any clamps or screws that secure the valve in place. It’s essential to have the right tools at hand to facilitate this process, which may include wrenches, pliers, and screwdrivers of various sizes.

As the old valve comes free from its mount, take note of any gaskets or seals present. These components may need replacing, as they play a crucial role in maintaining proper seal integrity within the system. Take care to inspect the housing for any signs of damage that may have contributed to the valve’s malfunction.

INSTALLING THE NEW SOLENOID VALVE

Having successfully removed the old valve, it’s time to install the new instrument. Begin by ensuring that the new solenoid valve is compatible with the existing setup. Once confirmed, place the valve into its designated position and secure it using the appropriate fasteners.

Next, attach the electrical terminals by connecting the marked wires to their respective places to facilitate proper function. Ensure that all connections are tight and free from corrosion. After securing the electrical and fluid connections, it’s imperative to install new seals or gaskets where necessary to prevent fluid leaks upon reactivation.

TESTING THE SYSTEM POST INSTALLATION

Once the new solenoid valve is in place, the installation phase is complete, but the work is not yet finished. Before fully reactivating the solar energy system, a series of tests should be conducted to gauge the effectiveness of the new valve.

Starting with a visual inspection, ensure that all connections are secure, and there are no visible leaks. Following this, power the system back on gradually, monitoring for any irregularities. If the solenoid valve opens and closes as intended, it indicates successful installation. Moreover, testing the system’s overall functionality post-installation ensures that no additional issues have arisen during the process, which further guarantees robust performance.

REGULAR MAINTENANCE OF SOLENOID VALVES

To prolong the lifespan of the solenoid valve within the solar energy system, regular maintenance becomes integral. This includes routine inspections, tightening of connections, and replacement of any worn-out parts such as seals or gaskets.

Establishing a maintenance schedule that aligns with the seasonal cycles of solar energy usage can significantly enhance the valve’s durability. By proactively addressing potential issues, homeowners can avert costly repairs and ensure their solar energy system operates at peak performance for years to come.

SEEKING PROFESSIONAL ASSISTANCE

While replacing a solenoid valve is manageable for individuals with a moderate level of technical expertise, there are instances where professional assistance may be warranted. Systems exhibiting persistent issues may require diagnostic capabilities beyond average consumer knowledge.

Engaging with trained technicians ensures a thorough evaluation of the system, potentially uncovering underlying faults not immediately apparent. Additionally, utilizing professionals may provide peace of mind, ensuring the installation adheres to local codes and industry standards.

COMPARISON OF SOLENOID VALVES

When considering the replacement of a solenoid valve, it may be worth comparing different types available on the market. Solenoid valves come in various forms, including normally open, normally closed, direct acting, or pilot operated. Each type serves different applications and functions within a solar energy system.

Selecting the appropriate type is vital to achieving desired efficiency levels. For example, a normally closed valve may be suitable for applications needing high safety standards, while a normally open valve might be preferable for continuous flow in specific systems. Understanding these distinctions allows for more informed decision-making during the replacement process.

FREQUENT INQUIRIES

WHAT IS A SOLENOID VALVE, AND HOW DOES IT FUNCTION?

A solenoid valve serves as a fundamental automation device that controls fluid flow within various systems, including solar energy setups. Its operational principle revolves around an electromagnetic coil that, upon receiving electrical input, elongates or retracts, influencing the valve’s opening or closing mechanism. This electronic actuation permits fine-tuned control over the liquid or gas passing through the valve.

In the context of solar energy systems, solenoid valves play a crucial role in regulating the circulation of heat transfer fluids between solar collectors and storage units. By effectively managing fluid pathways, these valves contribute significantly to maintaining energy efficiency throughout the solar energy system. Regular assessments and timely replacements of malfunctioning solenoid valves are essential to ensure optimal operation.

HOW OFTEN SHOULD SOLENOID VALVES BE REPLACED?

The replacement frequency of solenoid valves can vary based on several factors, including the system’s operational environment, quality of the valve, and the frequency of its cycling. Typically, if a solenoid valve is maintained regularly and used appropriately, it may last anywhere from five to ten years. Nevertheless, certain conditions could accelerate wear and necessitate earlier replacements.

For instance, exposure to extreme temperatures, working with corrosive fluids, or experiencing repeated malfunctions can all affect the longevity of a valve. Regular inspections and adhering to a systematic maintenance schedule are key strategies in identifying wear and tear early, ultimately aiding in determining the right time for replacement.

CAN I REPLACE THE SOLENOID VALVE MYSELF?

Replacing a solenoid valve can be a manageable task for those with competency in mechanical and electrical work. Individuals should possess basic tool handling skills and a clear understanding of their solar energy system’s operation before proceeding with the replacement.

While many people successfully perform a DIY replacement, instances do exist where professional help may be advisable. If the individual feels uncertain or lacks relevant experience, it is safer to consult with a technician. Seeking professional assistance not only ensures compliance with local regulations and safety standards but guarantees that installation processes are executed correctly, enhancing overall system reliability.

**Implementing a new solenoid valve within a solar energy system is a detailed process requiring appropriate knowledge and careful execution. Critical steps involve comprehensive assessments of the existing system, rigorous safety precautions, and meticulous installation procedures. Following an evaluation, the unit must be disconnected from power and de-pressurized to ensure a safe working environment. The replacement involves removing the old valve and setting the new components in place, inclusive of securing electrical terminals and ensuring proper sealing to avoid leaks.

Moreover, post-installation testing is necessary to confirm functionality and verify the overall performance of the solar energy system. Regular maintenance, including inspections and timely part replacements, has an immense impact on the longevity and reliability of solenoid valves. For more complex systems, seeking professional assistance remains beneficial, ensuring compliance and optimal performance. Assessing and comparing different solenoid types allows for informed decisions that contribute to enhancing energy efficiency. Engagement in preventative strategies will ultimately facilitate smooth operation and mitigate costs associated with unexpected malfunctions over time.**

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-replace-the-solenoid-valve-of-solar-energy/