To successfully replace a broken solar thermal insulation tube, one must follow a systematic approach. 1. Assess the damage thoroughly, as this helps in making informed decisions about the specific replacement required. 2. Gather necessary tools and materials, ensuring the right equipment is at hand for a seamless process. 3. Shut off the system, as safety must take precedence before any repair work starts. 4. Remove the damaged tube carefully, avoiding damage to surrounding elements. The next vital step is 5. Install the new insulation tube, ensuring proper alignment and sealing to maintain system efficacy. 6. Test the system post-repair, which is crucial to ensure everything is functioning as expected. Among these steps, the assessment of the damage requires meticulous attention; identifying whether just the insulation tube is compromised or if other components are affected is essential since this influences both the replacement process and the overall efficiency of the solar thermal system.

1. UNDERSTANDING SOLAR THERMAL INSULATION TUBES

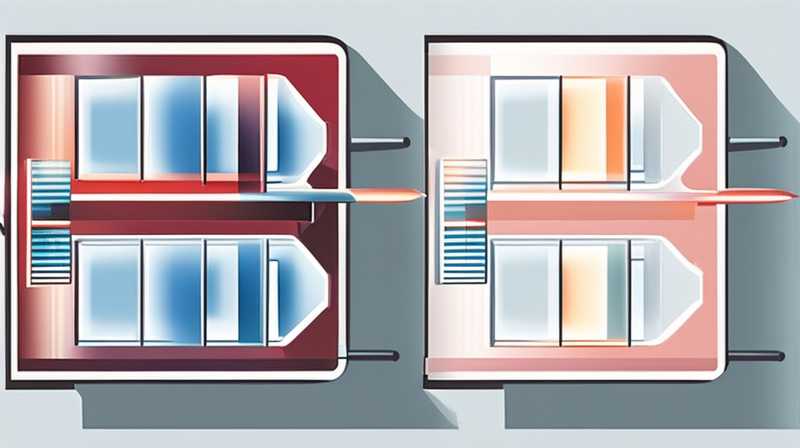

In the realm of solar thermal systems, insulation tubes play an integral role. These pipes are designed to prevent heat loss as hot water travels through them to the storage tank or distribution system. The insulation material surrounds the tubing, trapping the heat produced by solar panels. Understanding their function elucidates why maintaining their integrity is critical, as any compromise can lead to reduced efficiency and wasted energy, ultimately increasing heating costs.

The most common materials used for insulation tubes include fiberglass, foam, and other materials engineered for high-temperature endurance. The level of insulation directly impacts the performance of the entire solar thermal system. For instance, a well-insulated tube minimizes heat loss and can substantially enhance the overall system efficiency, allowing homeowners and businesses to reap more significant benefits from solar energy investments. Any breach in integrity can result in significant energy inefficiencies, making replacement a priority when damage occurs.

2. IDENTIFYING DAMAGE IN SOLAR THERMAL INSULATION TUBES

Before embarking on a replacement journey, it is crucial to evaluate the condition of the solar thermal insulation tube. Several factors can lead to deterioration, including environmental exposure, mechanical damage, or simply the passage of time. Various signs can indicate a broken tube, such as increased energy costs, visible cracks, or even physical deformation of the insulation. Hence, inspecting both the tubes and surrounding areas becomes a necessity.

Moreover, one must consider the broader ramifications of damaged insulation. A compromised tube not only signifies inefficiencies but may also lead to more significant system failures if left unaddressed. Having an understanding of wear patterns can aid in proactive maintenance, thereby extending the operational lifespan of the solar thermal system. The assessment phase serves as the foundation for informed decision-making when it comes time to replace the tubes.

3. TOOLS AND MATERIALS NEEDED FOR REPLACEMENT

Equipping oneself with the right tools is essential when undertaking the replacement of solar thermal insulation tubes. A comprehensive toolkit usually includes a pipe cutter, adjustable wrench, insulating tape, and possibly additional protective gear like gloves and goggles. Precise tools are critical for dismantling existing tubes and ensuring clean cuts and fittings for the new installations.

In addition to tools, choosing the correct materials is paramount. Selecting high-quality insulation materials designed for enduring high temperatures can prevent future issues. It is advisable to consult with the manufacturer to obtain recommendations on insulation types that match the existing system’s specifications. Investing in superior quality can yield tangible long-term benefits, enhancing both durability and insulating properties, ensuring that the system remains efficient for years to come.

4. SHUTTING OFF THE SOLAR THERMAL SYSTEM

Safety is the utmost priority during any maintenance operation. Before initiating the replacement process, disconnecting the solar thermal system is indispensable. This step typically involves switching off the circulation pumps and closing any valves connected to the solar collectors. Additionally, it is wise to drain the system to avoid any accidents involving scalding hot water or unexpected pressure releases.

Adequate precautionary measures, including using personal protective equipment, can further mitigate risks. Working on a de-energized and drained system allows one to perform maintenance comfortably and confidently. Post replacement, ensuring that the system is properly reconnected is critical to restore full functionality. This step ensures reliability, as the risks associated with improper handling during maintenance can lead to severe consequences.

5. REMOVING THE DAMAGED INSULATION TUBE

With safety precautions in place, the next logical step is to take out the broken insulation tube. Utilizing the pipe cutter, one must carefully make cuts around the damaged area, ensuring to remove any affected sections without damaging adjacent tubes or systems. This process may involve some disassembly of connected parts, but taking the time to identify and loosen or disconnect these components will lead to a smoother operation.

After detachment, it is advisable to inspect surrounding components for potential wear or damage. During this stage, cleaning the connection points of any residual sealant or debris is vital for a secure fit with the new tube. Minimizing contaminants at connection points can enhance seal integrity, thereby prolonging the system’s efficiency. Thus, thorough preparation is essential for successful reinstallation.

6. INSTALLING THE NEW INSULATION TUBE

Once the damaged section has been successfully removed, the focus shifts to installing a new insulation tube. It is crucial to ensure that the selected tube matches the required specifications for both length and insulation properties. Following the manufacturer’s guidelines, the new insulation tube should fit snugly around the existing piping to create a robust thermal barrier.

Properly sealing the connections is as important as selecting suitable materials. Fastening tape or other sealing agents can greatly enhance joint integrity, preventing potential leaks and loss of heat. Post-installation care also involves double-checking for any defects that could compromise the system. Adjustments may sometimes be necessary to achieve optimal alignment, further underscoring the attention to detail that must be applied throughout this process.

7. TESTING THE SYSTEM AFTER REPLACEMENT

After successfully installing the new insulation tube, the moment of truth arrives: testing the solar thermal system. Gradually bringing the system back online after replacement allows for a careful observation of its performance. Initial checks should include monitoring for any leaks around the newly installed sections and verifying that the system heats water effectively without excessive heat loss.

Running the system through its normal operational cycle can reveal hidden flaws that were not immediately apparent. During this phase, calculating performance metrics related to energy savings and heat retention over time can yield valuable insights. Documenting these evaluations forms a basis for continued maintenance and can signal when future inspections or replacements might be necessary.

FAQs

WHAT SIGNS INDICATE THAT A SOLAR THERMAL INSULATION TUBE IS DAMAGED?

Several indicators may suggest that a solar thermal insulation tube has sustained damage. One prominent sign is increased energy consumption. If the system requires more energy to heat water or maintain desired temperatures, it may point to a breach in the insulation. Another prevalent sign includes visible wear and tear on the insulation material, such as cracks, holes, or deformation. Instances of moisture or condensation around the tubing can also serve as early warning signs of insulation failure. Keeping a vigilant eye on these symptoms and conducting regular inspections can help you catch potential issues before they escalate into significant problems.

Not only could damage in insulation tubes lead to efficiency losses, but it may also result in more serious issues within the entire solar thermal system. Hence, recognizing these early signals is critical for preventing costly repairs and maintaining optimal system performance over time. For the long-term health of the solar thermal installation, it is advisable to schedule routine assessments to ensure all components remain in good working condition.

CAN I REPLACE THE INSULATION TUBE BY MYSELF OR SHOULD I HIRE A PROFESSIONAL?

The question of self-repair versus hiring a professional for the replacement of a solar thermal insulation tube depends on various factors, including your level of expertise, comfort with DIY tasks, and knowledge of plumbing systems. Those with background experience in home maintenance or mechanical work may feel confident taking on this project themselves, particularly with adequate tools and a thorough understanding of the system’s layout. However, it is essential to approach the job with care to avoid causing further damage or compromising safety.

On the other hand, engaging a professional can bring many advantages. A qualified technician possesses extensive experience and can identify underlying issues not readily apparent to an untrained eye. This added layer of expertise often results in more efficient repairs, less risk of future complications, and peace of mind regarding system integrity. Weighing personal capability against the potential complexities of the task at hand will aid in making the best decision for your circumstances.

HOW OFTEN SHOULD I CHECK MY SOLAR THERMAL INSULATION TUBES?

Regular maintenance is crucial for the longevity and efficiency of any solar thermal system, and this extends to insulation tubes as well. It is advisable to conduct visual inspections at least once or twice a year. These checks should focus on identifying visible signs of damage such as cracks, separation of insulation layers, or any water stains that may indicate leakage. Additionally, seasonal maintenance, especially before and after heavy usage periods, can help in pinpointing potential problems.

In addition to visual inspections, consider monitoring the system’s performance closely. Noticing an increase in energy consumption or fluctuations in water temperature can prompt a deeper investigation into the condition of the insulation tubes. Early intervention becomes critical; the sooner issues are remedied, the more efficiently the solar thermal system can operate. Scheduling professional assessments every few years can offer additional insights regarding system health and possible upgrades.

Effective replacement of a broken solar thermal insulation tube requires a proactive approach and attention to detail. Regular assessments are instrumental in maintaining overall efficiency and performance, acting as a deterrent against future complications. Proper steps include careful diagnosis, appropriate tool selection, and ensuring alignment during the installation of the new material. Monitoring system efficacy post-repair serves to validate the maintenance efforts undertaken. With the right understanding and practice, one can significantly enhance the functionality and sustainability of solar thermal systems, ensuring a lasting benefit for both the environment and energy savings.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-replace-the-solar-thermal-insulation-tube-if-it-is-broken/