To successfully replace the solar solenoid valve switch, several essential steps must be followed meticulously, such as 1. Identifying the correct valve switch needed for your solar system, 2. Shutting off the power supply to avoid any electrical risks, 3. Disconnecting the old solenoid valve switch properly, and 4. Installing the new solenoid valve switch with attention to wiring and configuration. Among these points, proper identification of the right valve switch is crucial since compatibility varies by model and system specifications, impacting the entire solar system’s performance.

1. UNDERSTANDING SOLAR SOLENOID VALVE SWITCHES

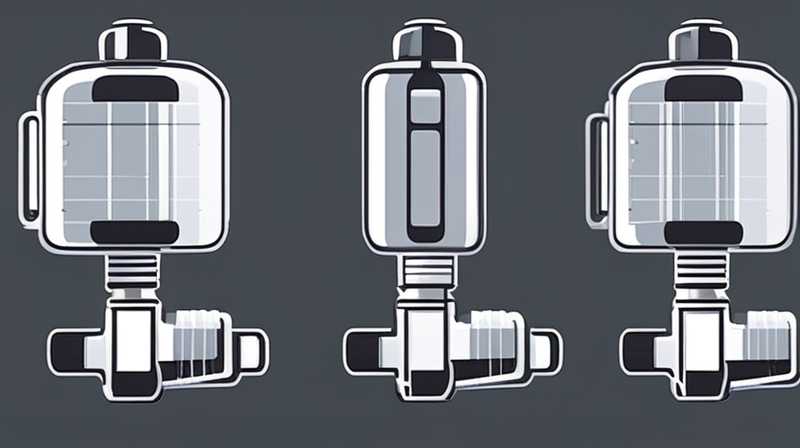

Solar solenoid valve switches are integral to the operational efficiency of solar-powered irrigation systems and other solar applications. They control the flow of water or fluid based on electrical signals, acting as automated regulators that ensure appropriate water distribution or system functionality. Their functionality relies heavily on reliable electrical and hydraulic connections.

Understanding their role and how they operate provides context for why effective replacement is essential. For instance, when crops need water, the valve switch signals the opening or closing of waterways, making it critical that these components function flawlessly. A malfunctioning valve can disrupt entire systems, leading to insufficient irrigation which can negatively affect crop yield or solar energy efficiency.

Moreover, solenoid valve switches can differ in design, voltage ratings, and operational mechanisms. Hence, knowing the specifications of your system is vital before initiating the replacement process. This enables the selection of the correct model tailored to your specific needs.

2. GATHERING NECESSARY TOOLS AND MATERIALS

Before embarking on the replacement task, one must gather the requisite tools and materials to ensure a smooth operation. Common tools include screwdrivers, wrenches, wire cutters, and multimeters, each serving a distinct purpose in the removal and installation process. Ensuring you have the right tools at hand prevents interruptions while working.

In addition to tools, having the correct replacement solenoid valve switch on hand is imperative. Choosing a high-quality switch that matches the specifications of the original component ensures compatibility and longevity. Researching these specifications can save significant time and potential frustrations.

While it may seem practical to use any available materials, using alternatives can lead to suboptimal performance and potential damage. For example, using an ill-fitting valve may cause leaks or improper fluid flow, which can ultimately result in additional costs for repairs or replacements.

3. SAFETY MEASURES BEFORE STARTING

Before proceeding with the replacement, taking safety precautions is integral to protecting oneself and the integrity of the solar system. The first and most crucial step is to shut off the power supply to the system entirely. This precaution prevents accidental electrical shock and other hazards that may arise during the process.

Wearing personal protective equipment (PPE) such as gloves and safety glasses while working provides an extra layer of protection. Some risks can arise from handling electrical components or sharp objects during the installation, and adequate safety gear can mitigate these potential risks.

Reading the manufacturer’s instructions and guidelines regarding the specific solenoid valve switch also contributes to safety. Each model may have its own set of precautions based on its design and functionality. Following these instructions not only helps in ensuring safety but also enhances the likelihood of a successful and efficient replacement process.

4. REMOVING THE OLD SOLENOID VALVE SWITCH

Once safety measures are in place, focus shifts to the removal of the existing solenoid valve switch. Start by locating the switch within the system. It typically is connected to wiring and possibly additional components like the controller or solenoid valve. Carefully document how everything is connected, as this will assist with the installation of the new switch. Using a diagram or photos during this step is often beneficial.

Upon locating the switch, disconnect all attached wires. Use wire cutters or electrical tape as necessary but ensure that the power to the circuit remains off throughout this process. Labeling each wire during disconnection can prevent confusion when reconnecting them.

Remove the bracket or screws securing the switch. These fasteners can sometimes be rusted or corroded, requiring additional effort to extract them. In such cases, applying a penetrating oil or an effective rust remover may facilitate easier removal. Following this step, the old switch should be detached and ready for replacement.

5. INSTALLING THE NEW SOLENOID VALVE SWITCH

With the old solenoid valve switch removed, attention turns to installing the new component. Begin by positioning the new switch in the same location as the original. Installation often requires aligning the switch properly with the existing bracket or mounting screws to ensure stability and functionality.

Once positioned, securely bolt in the new switch. Make sure the connections are tight, as loose connections can lead to electrical failures or sporadic operation of the solar system. Following this, carefully reconnect the wiring according to the documentation or images taken earlier. Ensure each connection is secure to avoid operational issues later.

After everything is installed, it’s essential to conduct a thorough check. This includes inspecting all connections for correctness and looking for any potential leaks or electrical issues. Testing the system is often advised at this juncture to verify that the new switch operates as intended and that the overall system is functioning optimally.

6. TESTING THE NEW INSTALLATION

Once the new solenoid valve switch is in place, conducting a comprehensive test is vital to ascertain proper functionality. Begin by restoring power to the solar system gradually, observing the behavior of the new component. Check for any abnormal sounds or behaviors during this initial phase.

Once the power is restored, initiate a testing cycle to encourage the solenoid valve to open and close. This process typically involves either manually activating the system or employing a controller to observe the switching action. Monitoring the response of water flow, pressure, and other relevant metrics confirms that the solenoid valve switch is operating efficiently.

If the tests yield satisfactory results, document the successful replacement for future reference. These records will aid anyone who may work on the system later by providing insights into the service history and specific changes made. However, if issues arise, further inspection may be needed to troubleshoot potential problems effectively.

FREQUENTLY ASKED QUESTIONS

WHAT IS A SOLENOID VALVE SWITCH?

A solenoid valve switch is an electromechanical device that regulates the flow of fluids or gases within a system. It functions by converting electrical energy into mechanical movement to open or close the valve, allowing for controlled distribution of resources such as water in solar irrigation systems. Proper operation is critical for system efficiency, as malfunctions can disrupt the entire water management system.

Solenoid valve switches come in varying designs that cater to different operational requirements, including various voltages, materials, and sizes, impacting their application in specific contexts. When choosing a switch, it’s essential to consider compatibility with existing components and ensure that it meets the necessary specifications for effective performance.

HOW OFTEN SHOULD SOLENOID VALVE SWITCHES BE REPLACED?

The longevity of a solenoid valve switch largely depends on various factors such as usage frequency, environmental conditions, and system maintenance. Generally, it is advisable to conduct routine inspections at least every six months or annually, particularly before critical seasons in agriculture or peak solar operations.

Wear and tear from factors such as sediment buildup, corrosion, or electrical surges can significantly shorten the lifespan of these components. If a switch exhibits problems such as slower response times, inconsistent operation, or signs of physical damage, it may signal the need for replacement.

Regular maintenance helps identify potential issues early, prolonging the lifespan of the solenoid valves and ensuring optimal system performance. Proper documentation of inspections and replacements can also provide valuable data for future troubleshooting and maintenance planning.

CAN I INSTALL A SOLENOID VALVE SWITCH MYSELF?

Yes, but it is critical to follow proper procedures and safety guidelines to ensure a successful installation. Those with a basic understanding of electrical systems, plumbing, and mechanical devices can typically undertake the replacement. However, it’s essential to approach the task with caution, adhering strictly to safety procedures to mitigate risks associated with electrical work.

If unfamiliar with the system or the installation process, consulting user manuals, and resources, or seeking professional assistance might be wise. Engaging with an experienced technician or peer can enhance understanding and provide guidance for more intricate installations. Investing time in thorough research and preparation ensures a smoother process while minimizing the risk of operational failures later.

SIGNIFICANT TAKEAWAYS

Successfully replacing a solar solenoid valve switch involves a series of carefully planned steps to ensure everything functions optimally. Identifying and procuring the correct replacement part is foundational, facilitating ease during installation. Following rigorous safety measures helps mitigate risk throughout the process, allowing for efficient work without unforeseen hazards.

The removal of the old switch requires meticulous attention, ensuring accurate documentation for proper reinstallation. The installation of the new switch not only demands precision but also benefits from comprehensive testing to confirm functionality. Being thorough in documentation post-installation enhances maintenance in the future, providing valuable insights to those who may work on the system subsequently.

Regular inspections and considerations regarding when to replace these components can significantly influence the efficiency of solar systems. By nurturing a proactive approach, users can enhance their systems’ resilience and efficiency, preventing cascading failures that might arise from neglect. Vigilance in maintenance, combined with the the right knowledge of the specific system in place, distinguishes successful solar applications from those hindered by component failure.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-replace-the-solar-solenoid-valve-switch/