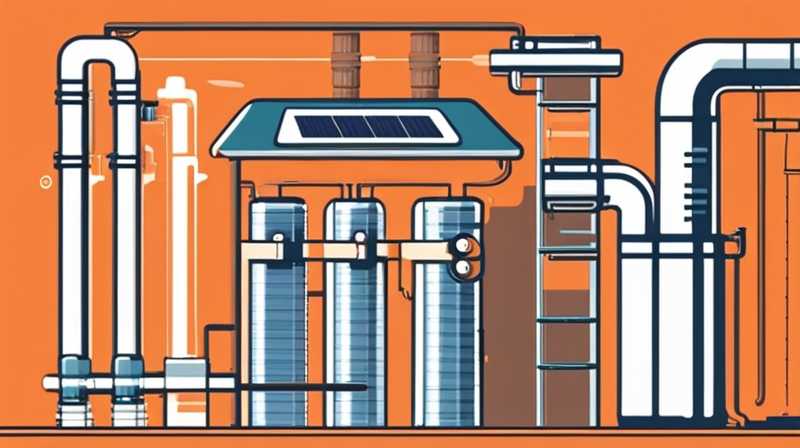

To replace the solar indoor pipe network, several steps must be undertaken to ensure a successful transition. 1. Assessing the existing infrastructure, evaluating the condition of the current piping is crucial, as it helps determine whether replacement is necessary or if repairs could suffice. 2. Selecting suitable materials, choosing the right materials that can withstand the specific temperatures and pressures related to solar systems is vital for maintaining efficiency and safety. 3. Disruption management, planning for proper ventilation and minimizing disruption during the transition will be essential to maintain long-term operational integrity. 4. Ensuring compliance with regulations, it’s imperative to understand regional regulations and codes governing solar installations to ensure compliance and smooth operation post-replacement.

By following these steps, the replacement process can be managed effectively, leading to optimized solar system performance.

1. ASSESSING THE EXISTING INFRASTRUCTURE

An essential element before proceeding with the replacement of solar indoor pipe networks is evaluating the existing piping infrastructure. Insight into the current state, age, and material of the pipes provides a clearer understanding of the challenges that might arise during the replacement process. This includes looking for signs of wear and tear, corrosion, and any obstructions that may affect fluid flow.

Every solar heating system depends on efficient fluid circulation to maximize its effectiveness. Hence, thorough inspections are paramount. By using tools such as thermal cameras or ultrasonic testers, professionals can detect subtle weaknesses in the pipes that might not be visible to the naked eye. Addressing these issues during the assessment phase can save time and resources in future maintenance.

After evaluating the current infrastructure, it becomes easier to identify whether a complete replacement is the best option or if targeted repairs could extend the functional life of the existing network. Considering cost-effectiveness and performance is key since many solar systems can operate efficiently for several years with proper maintenance.

2. SELECTING SUITABLE MATERIALS

Choosing the appropriate materials for the new pipe network significantly impacts the overall efficiency and longevity of the solar system. The prevalent materials in solar piping include copper, CPVC, and PEX, each presenting unique advantages. Copper offers excellent thermal conductivity and durability, making it a traditional choice, while CPVC, known for its resistance to corrosion, provides an alternative that can handle high temperatures without degrading.

PEX has gained popularity due to its flexibility, ease of installation, and resistance to freezing. The latter is particularly beneficial in cold climates where pipes risk damage from expansion when water freezes. However, the decision must also take into account local climate conditions, expansion and contraction due to temperature fluctuations, and the particular operational requirements of the solar system.

Furthermore, evaluating the environmental impact of the chosen materials adds another layer to the decision-making process. For instance, selecting sustainable alternatives may provide long-term benefits to both the system and the environment, aligning operational efficiency with responsibilities to reduce carbon footprints. Understanding and weighing these material properties ensures a well-informed choice that supports not just immediate functionality but the system’s future durability and performance.

3. DISRUPTION MANAGEMENT

Proper planning for disruptions arising during the pipe network replacement is crucial for maintaining continuity in solar energy operations. Given the critical nature of solar piping in system efficiency, ensuring minimal downtime is vital. Advance scheduling around peak operational periods and informing stakeholders about potential interruptions can help mitigate negative impacts.

Moreover, it’s important to prepare the surrounding area for any unforeseen issues that may arise during replacement. Establishing temporary bypass systems, where necessary, can keep the solar heating system operational while sections of the pipeline are being replaced. This approach not only maintains system performance but also enhances customer satisfaction through continuous service provision.

Another point to consider is health and safety protocols. Ensuring that work areas are secure and that all workers are equipped with necessary personal protective equipment (PPE) should be a priority. By prioritizing a safe work environment, the risks associated with injuries or accidents are minimized, promoting a smooth and efficient process. As the replacement progresses, regular updates and communication with all involved parties will foster patience and understanding, leading to a collaborative effort towards project goals.

4. ENSURING COMPLIANCE WITH REGULATIONS

Compliance with local, state, and federal regulations is a non-negotiable aspect of replacing a solar indoor pipe network. Various jurisdictions impose specific codes regarding the installation and maintenance of solar energy systems, aiming to safeguard the environment and public safety. This necessitates a thorough examination of applicable regulations before initiating any project.

In many areas, obtaining necessary permits serves as a prerequisite for starting work on the piping replacement. Engaging with local agencies or consultants can clarify what documentation is required and streamline the approval process. The importance of maintaining compliance extends beyond initial installations, as routine inspections may occur during the system’s life cycle.

Beyond the legal implications, maintaining compliance contributes to operational straightforwardness. When systems adhere to the specified standards, it often results in enhanced efficiency, potentially leading to lower operational costs. Stakeholders appreciate transparency throughout this process, as it fosters trust and encourages more comprehensive teamwork in future sustainability initiatives. The ramifications of non-compliance could lead to fines or mandatory decommissioning, underlining the necessity of thorough knowledge and adherence to all regulations in the solar industry.

FAQs

WHAT ARE THE MAIN REASONS FOR REPLACING A SOLAR PIPE NETWORK?

The motivations for replacing a solar indoor pipe network can vary significantly. One common reason involves the deterioration of existing pipes. Over time, factors such as corrosion, wear and tear from thermal cycling, and general degradation can diminish the efficiency of the solar heating system. Additionally, outdated piping materials may not meet current standards for thermal insulation or pressure tolerance, prompting a replacement initiative to enhance performance and safety. Another reason could be advancements in technology. As newer, more efficient materials and designs become available, homeowners and businesses may wish to update their systems to capitalize on these improvements. In some cases, expanding the solar array or altering the system to accommodate new technologies necessitates a complete overhaul of existing piping.

Inadequate or inefficient fluid flow within the current network can similarly trigger a replacement. If heating performance declines due to blockages or misalignments, addressing the underlying issues with outdated piping might warrant a full replacement instead of piecemeal repairs. Energy efficiency also plays a crucial role in the decision-making process; replacing old, inefficient pipes can lead to substantial long-term savings and better overall system performance. Overall, these factors combine to form a comprehensive rationale for undertaking the replacement of solar pipe networks, ensuring that renewable energy systems maintain their efficacy and sustainability.

HOW DO I PREPARE FOR THE REPLACEMENT PROCESS?

Preparing for the replacement of a solar indoor pipe network involves multiple steps that focus on planning and coordination. Initially, homeowners or facility managers should conduct thorough assessments of their existing systems, documenting issues, inefficiencies, or failures observed over time. Engaging certified professionals can enhance this evaluation, as their insights can shed light on the broader implications of current conditions and suggest the best solutions. Following this analysis phase, planning should proceed regarding when replacement work will occur to minimize disruption. Collection of relevant information regarding local building codes and solar regulations must occur concurrently; this may necessitate communicating with local authorities about necessary permits and inspections.

Resource allocation also plays a pivotal role in this preparation stage. Identifying needs for materials, tools, and labor will help impose clear budgets, aligning expectations with financial realities. Those involved should also compile contingency plans for potential issues that may arise during the replacement; this foresight could prevent lengthy delays associated with equipment failures or unforeseen complications. Lastly, communication with all stakeholders—including those who might be affected by the project—is crucial for maintaining smooth operations and managing expectations. Giving clear timelines and updates fosters understanding and collaboration throughout the replacement process.

WHAT MATERIALS ARE BEST FOR SOLAR PIPE INSTALLATION?

When considering materials for solar pipe installation, multiple factors come into play, including performance, durability, and environmental impact. Notably, copper pipes are widely recognized for enduring high temperatures and pressures along with exceptional thermal conductivity. This allows for efficient heat transfer within solar heating systems, contributing positively to overall performance. However, they may also be more costly than alternative materials, which can deter some installations. Conversely, CPVC pipes present an attractive option due to their resistance to corrosion and ease of handling, though care must be taken to ensure they are suitable for the specific thermal conditions encountered in solar applications.

Incorporating PEX into solar installations has gained popularity due to its flexibility and resistance to freezing, particularly in regions subject to extreme temperature fluctuations. PEX is also simpler to install, often resulting in lower labor costs, which can be beneficial when undertaking new projects or replacements. When making a decision regarding materials, it is imperative to consult relevant industry standards and guidelines. All materials should pass stringent performance specifications and be capable of withstanding the local climate for long-term success. Ultimately, the most effective solution often combines practicality with an awareness of evolving technologies in the solar sector, ensuring energy systems remain cutting-edge.

A FINAL THOUGHT

In summary, tackling the replacement of a solar indoor pipe network requires meticulous preparation and informed decision-making. The process encompasses assessing the existing infrastructure, selecting suitable materials, managing potential disruptions, and ensuring compliance with relevant regulations. Each step contributes to a seamless transition, guaranteeing sustained solar system performance and efficiency. Ultimately, the commitment to thorough planning and awareness of industry trends can elevate a solar installation’s efficacy, supporting broader sustainability goals in renewable energy deployment. Updated systems not only enhance the reliability of energy outputs but serve as a testament to the ongoing evolution of green technology.

When contemplating the replacement of a solar indoor pipe network, it is crucial to recognize the key factors that shape the decision. Careful assessment of existing structures identifies potential weaknesses and helps determine if a replacement is warranted, while selecting appropriate materials ensures long-term durability and efficiency. Addressing disruption is vital to minimize downtime, necessitating proper planning and preparedness. Further, compliance with local regulations cannot be overlooked, as it serves to protect the investment and enhance safety during and after installation. Engaging professionals and gathering all necessary information will support a successful transition to an efficient solar heating system. A well-executed replacement strategy ultimately fosters increased sustainability, efficiency, and reliability in energy systems, aligning with the goals of reducing carbon emissions while ensuring our energy needs are effectively met.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-replace-the-solar-indoor-pipe-network/