To replace the solar heat preservation tube, follow these steps: 1. Gather necessary tools and materials, 2. Drain the existing system, 3. Remove the old tube carefully, 4. Install the new tube, ensuring proper sealing, and 5. Refill the system and check for leaks. A detailed explanation of ensuring proper installation is critical, as a faulty connection can lead to inefficiency.

REPLACING A SOLAR HEAT PRESERVATION TUBE

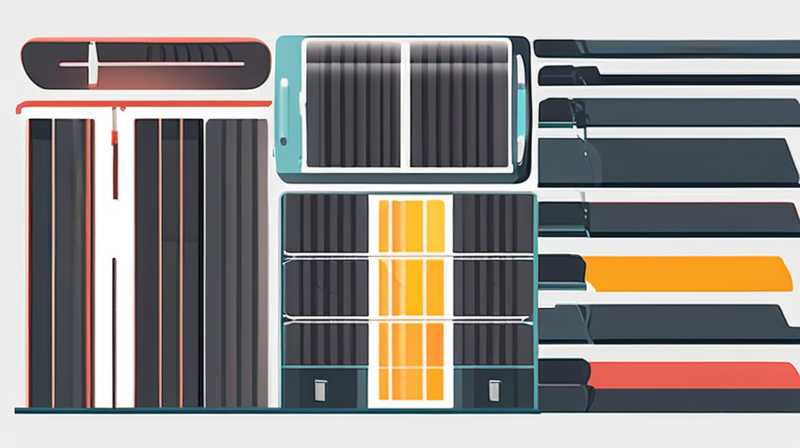

UNDERSTANDING THE SOLAR HEAT PRESERVATION TUBE

The solar heat preservation tube plays a pivotal role in maintaining the efficiency of solar heating systems. To comprehend its importance, it is essential to delve into its function and design. This tube is engineered to prevent heat loss during daytime storage and nighttime usage, ultimately ensuring that the solar energy harnessed is used effectively. The materials used in manufacturing these tubes can significantly affect their thermal efficiency. From high-density polyethylene to multilayer composites, the choice of materials can influence longevity, thermal conductivity, and overall performance.

Moreover, one must recognize that certain factors can lead to the degradation of these tubes over time. Exposure to ultraviolet rays, extreme temperature fluctuations, and chemical reactions can all compromise the integrity of the tube. Regular inspections can help in identifying wear and tear, enabling timely replacements and ensuring sustained efficiency. This proactive approach not only enhances the system’s reliability but also curtails potential unforeseen costs associated with system failure.

TOOLS AND MATERIALS NEEDED

Before embarking on the replacement process, identifying the requisite tools and materials is crucial. A wrench, screwdriver, and pipe cutter are fundamental tools, along with the new solar heat preservation tube that matches the specifications of the original installation. It is also advisable to have Teflon tape or pipe sealant available to ensure leak-proof connections. Having these tools at hand simplifies the process, minimizing the chances of interruption.

Furthermore, utilizing quality materials cannot be overstated. Selecting a tube that meets or exceeds performance standards will result in better thermal retention and durability. Manufacturers often provide specifications that assist in choosing the right tube, and relying on these guidelines can lead to successful installations. Investing in high-quality replacement components is essential to maintaining the efficiency and lifespan of solar heating systems.

DRAINING THE SYSTEM

Once the tools and materials are gathered, the next critical step involves draining the existing system. This process ensures safety and prevents any residual fluid from causing mess or contamination. Begin by shutting off the power supply and ensuring the system is completely cool. If a glycol-based fluid is used within the system, special care must be taken to dispose of it properly according to local regulations. This step is essential for environmental safety and compliance.

After the power shutdown, locate the drain valve, typically located near the lowest point of the system. Open this valve slowly, allowing the fluid to exit the system without creating excessive pressure or spillage. To expedite the process, consider using a siphoning method to remove the remaining fluid. Additionally, ensuring that there are containers to collect drained fluids will mitigate any accidental spills, keeping the surrounding area safe and clean.

REMOVING THE OLD TUBE

With the system drained, the next phase involves extracting the old tube. Begin by loosening the clamps or connectors securing the tube in place. It is advisable to use the appropriate wrench or screwdriver for this task to prevent damage to the connectors. Take care while handling these components, as excessive force may lead to cracks or breaks that could complicate future installations.

During this process, focus on the connection points carefully. Inspect the existing components for any signs of wear or damage. It is prudent to document the orientation and placement of the old tube before removal. This attention to detail will facilitate the installation of the new tube, ensuring that all connections are correctly aligned. Once fully detached, set the old tube aside for proper disposal according to local waste management guidelines.

INSTALLING THE NEW TUBE

Installation of the new tube is a critical stage, and one must approach it with precision. Begin by lining up the new tube with the existing connection points, ensuring that the orientation matches that of the old tube. Use Teflon tape or pipe sealant on threads to create a tight seal and prevent leaks. Tighten the connectors gently but firmly, being careful not to overtighten, as this could cause damage to the fittings.

Following installation, it is crucial to recheck the entire system for any potential alignment issues or misfits. Double-checking connections will ensure that the tube is secured and positioned accurately, preventing future complications. After affirming the integrity of your work, prepare to refill the system, completing the installation with care.

REFILLING THE SYSTEM

Refilling the system follows the successful installation of the new tube. Start by closing the drain valve once you have verified that all connections are secure and leak-free. Gradually refill the system with the appropriate fluid, ensuring that all air pockets are purged. Utilizing an expansion tank during this process can help in managing the fluid levels effectively, preventing excessive strain on the system.

Monitor the pressure gauge throughout this process. Adequate pressure is necessary for optimal system performance, and any declines could suggest leaks or other technical issues. Once the system is appropriately filled, activate the power supply and allow the system to reach normal operating conditions.

CHECKING FOR LEAKS

Once the system is operational, addressing potential leaks becomes vital. Use a mixture of soapy water to check along all joints and connections. If bubbles form, it indicates a leak that needs immediate attention. Promptly tightening connections or applying additional sealant can rectify minor issues.

Regular monitoring during the initial days of operation is advisable. Keep track of performance metrics to ensure the newly installed tube is functioning as expected and contributing to the system’s overall efficiency.

MAINTAINING THE SYSTEM POST-REPLACEMENT

The completion of a tube replacement doesn’t signify the end of maintenance efforts. Regular inspections and maintenance routines can significantly extend the lifespan of the solar heating system. Schedule periodic checks for signs of wear and tear, such as cracks, leaks, or disconnections.

Moreover, cleaning the system components can boost efficiency. Dust, dirt, or scaling can impede performance, leading to reduced heat absorption. Investing time in routine maintenance will mitigate larger issues down the line and ensure sustainability, highlighting the integrity of the newly installed tube.

FREQUENTLY ASKED QUESTIONS

WHAT CAUSES THE NEED TO REPLACE A SOLAR HEAT PRESERVATION TUBE?

The need for replacing a solar heat preservation tube can arise from various factors that contribute to wear and degradation. Environmental conditions, such as exposure to UV rays, harsh weather, and temperature fluctuations, can significantly shorten the lifespan of such tubes. Additionally, chemical reactions with fluid circulating through the system can lead to breakdown and cracks in the material. Regular inspections can reveal wear and provide insight into the tube’s condition. If signs of oxidation, leaks, or thermal inefficiency are evident, it may be time to consider a replacement.

Another critical factor is performance deterioration over time. With time, the insulation properties of the tube may degrade, leading to excessive heat loss. A significant drop in system efficiency often triggers the need for replacement, prompting users to upgrade or maintain optimal performance levels. Not addressing these issues can lead to increased energy costs and reduced system reliability, making proactive maintenance vital.

HOW DO I KNOW WHEN IT’S TIME TO REPLACE MY SOLAR HEAT PRESERVATION TUBE?

Identifying the right moment to replace a solar heat preservation tube requires vigilant observation of system performance and physical condition. Typically, signs such as visible cracks, significant discoloration, or softened areas on the tube indicate a need for replacement. System inefficiencies manifest through higher energy bills, inconsistent hot water supply, or underperformance noted during routine use.

Monitoring temperature readings can also reveal deficiencies in the system. If temperature retention fails to meet expectations, further investigation may discover internal problems associated with the preservation tube. By staying attuned to these indicators, users can act promptly, ensuring that the solar heating system continues to operate effectively and sustainably.

IS IT POSSIBLE TO REPLACE THE SOLAR HEAT PRESERVATION TUBE MYSELF, OR SHOULD I HIRE A PROFESSIONAL?

For those considering the replacement of a solar heat preservation tube, evaluating one’s skills and comfort level with DIY projects is essential. Undertaking this task independently is feasible if one possesses adequate mechanical aptitude and a comprehensive understanding of the system components. Following proper guidelines and safety protocols can lead to successful implementation.

However, enlisting a professional may prove beneficial for those unsure of their capabilities or those who prefer a guarantee of thoroughness and accuracy. Professionals bring experience, knowledge of common pitfalls, and access to specialized tools, ensuring a seamless and effective replacement process. Ultimately, the choice depends on personal confidence, technical ability, and the complexity of the installation.

FINAL THOUGHTS

Replacing a solar heat preservation tube is an intricate procedure that requires thorough knowledge, appropriate tools, and a keen attention to detail. From understanding the importance of the tube in the solar heating system to gathering necessary materials, each step plays a crucial role in the success of the operation. Proactive measures, such as routine inspections and timely replacements, can greatly enhance system efficiency and longevity, ensuring an optimal return on investment.

Moreover, it is imperative to recognize the necessity of both immediate action and long-term planning in maintaining solar heating systems. Users must remain vigilant through ongoing monitoring, addressing any potential issues early to prevent compounded problems in the future. Engaging in proper maintenance, combined with periodic inspections, are essential strategies to sustain performance levels and ensure system reliability.

Investing time and resources into the effective replacement of a solar heat preservation tube will ultimately pay dividends, maintaining an efficient and cost-effective energy solution. Achieving this requires careful consideration of materials, methods, and a commitment to upholding system integrity through diligent maintenance practices. The journey of installation and oversight comes to define the effectiveness of solar heating systems, reflecting the necessity of optimal performance in today’s environmentally-conscious energy landscape.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-replace-the-solar-heat-preservation-tube/