To effectively replace a broken solar dark valve, one should follow these key steps: 1. Identify the issue accurately, 2. Gather essential tools and new components, 3. Remove the damaged valve carefully, 4. Install the new valve with precision. The identification process involves inspecting the system for leaks or inefficiencies linked to the valve. Gathering appropriate tools, including wrenches and screwdrivers, as well as acquiring a suitable replacement valve compatible with the existing installation, is crucial for a successful repair. The removal should be executed cautiously to avoid damage to adjacent components or plumbing. Finally, proper installation of the new valve ensures that the solar heating system functions effectively. The elaboration of the identification phase requires recognizing specific symptoms associated with the malfunction of the solar dark valve, which may include irregular temperature readings, unexpected drops in pressure, or visual indicators of wear. Understanding these aspects can guide one towards ensuring efficient corrective measures.

1. UNDERSTANDING THE SOLAR DARK VALVE

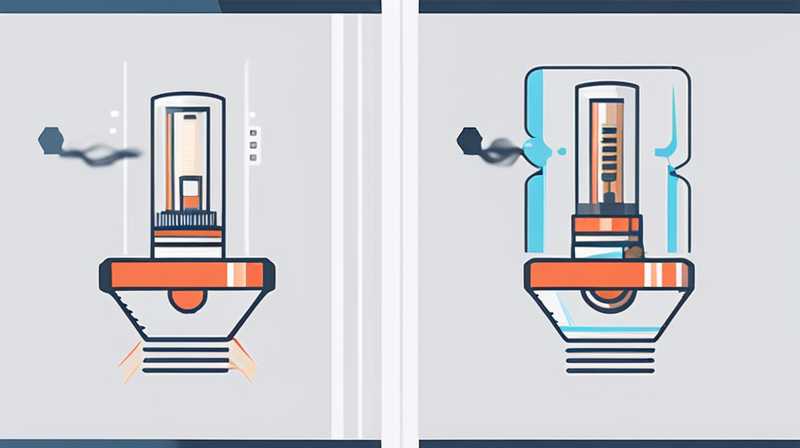

The solar dark valve plays a pivotal role in optimizing the efficiency of solar heating systems. It regulates the flow of heat transfer fluid between panels and storage tanks. By controlling the temperatures and managing pressures, it ensures that the maximum heat is captured from solar energy, leading to effective heating solutions. Any malfunction within this system can lead to significant inefficiencies and increased energy costs.

In essence, a solar dark valve typically consists of a body housing, sealing mechanisms, and actuation elements. These components work collaboratively to ensure that the heat transfer fluid operates within designated limits. The valve can be categorized into various types, such as manual, automatic, or electronic, each having unique characteristics that cater to specific needs. Understanding these categories is fundamental to diagnosing problems and determining the appropriate course of action for replacement or repair.

2. SIGNS OF A FAILURE

Recognizing the signs of a faulty solar dark valve is essential for preemptive maintenance and keeping systems functioning effectively. Several indicators suggest that a valve might require replacement. 1. Visible Leaks, 2. Inconsistent Temperature, 3. Unusual Noises. Each of these signs points to potential underlying issues within the solar thermal system.

Visible leaks, for instance, are a primary concern. When any component of the system experiences a malfunction, leakage can occur at the valve joints, leading to fluid loss. This condition not only diminishes efficiency but also contributes to the potential damage of other interconnected components. Closely observing connections, seals, and the valve body can provide visual evidence requiring immediate action.

Inconsistent temperature readings represent another critical red flag. If the output temperature deviates significantly from expected norms, it may indicate a blockage or obstruction in the valve mechanism. Regular monitoring of temperature readings can serve as a valuable indicator, allowing for diagnostics before severe system performance degradation occurs. Coupled with standard pressure readings, assess this information carefully as it provides invaluable insights.

3. GATHERING NECESSARY TOOLS

Prior to embarking on the replacement journey, it is imperative to procure the right tools and components essential for the operation. To successfully replace a damaged valve, 1. Basic Tools, 2. Replacement Components, 3. Safety Gear are of utmost importance.

Basic tools typically include adjustable wrenches, screwdrivers of various sizes, and pliers. Each of these assists in loosening and tightening fittings without causing undue strain on the components. A socket set may also benefit those attempting more complex tasks involving various hardware sizes. Preparation with these fundamental tools can prevent interruptions during the replacement effort.

Replacement components must align perfectly with the existing valve specifications. This careful measurement guarantees compatibility within the solar thermal system. Notably, selecting quality parts can significantly influence the longevity and reliability of the new installation. Furthermore, safety gear—such as gloves and goggles—cannot be overlooked, as these protect against unforeseen mishaps while working on potentially hazardous materials and equipment.

4. STEPS TO REPLACE THE VALVE

Executing the replacement of a solar dark valve should be approached methodically, maintaining precision at each phase. It is vital to follow a structured series of actions encompassing 1. System Shutdown, 2. Valve Removal, 3. Installation of New Valve.

Commencing with a complete system shutdown ensures that all energy sources are disconnected, thereby reducing the risk of accidental burns or leaks. This precautionary measure includes turning off pumps and isolating the heating circuits, which helps maintain operational safety.

Following the shutdown, one can cautiously begin detaching the broken valve. This step involves unscrewing and unfastening the connections, all while handling components delicately—especially those made from verdant materials or having delicate seals. A successful removal will involve assessing the condition of adjacent parts, which can often influence the new valve’s effectiveness.

Installing the new valve then becomes the focus. Care should be given to aligning connecting points correctly, ensuring secure fittings and proper sealing. Utilizing thread tape on threaded connections can help minimize future leaks. After the installation, gradually repressurizing the system allows for meticulous monitoring to determine if the replacement succeeded. Any signs of leaks or operational flaws should prompt immediate corrective measures.

5. TESTING AND ADJUSTMENTS

After installation, rigorous testing marks the next significant phase. Properly functioning solar dark valve systems should operate seamlessly without noticeable issues. 1. System Pressurization, 2. Temperature Calibration, 3. Monitoring Operation are critical during this assessment.

System pressurization involves gradually increasing pressure to the operational standards set in the system’s specifications while remaining vigilant for leaks around newly installed fittings. This incremental approach minimizes the risk of sudden failures and ensures adequate sealing, which is paramount to effective operation.

Subsequently, temperature calibration will assess how well the newly installed valve facilitates heat transfer fluid. The accuracy of temperature gauges should be vetted, ensuring they correspond with expected readings. Analog gauges may require cleaning and recalibration to retain accuracy in monitoring systems, and digital units may need adjustments based on the installation specifications.

Monitoring operation after establishing pressurization and checking gauges becomes essential. This phase should last several operational cycles, allowing for evaluation of the new valve’s performance under varying conditions. Consequently, maintain an eye out for leaks or abnormal sounds indicative of underlying issues.

FAQs

WHAT IS A SOLAR DARK VALVE, AND WHY IS IT IMPORTANT?

A solar dark valve serves a crucial function in solar thermal systems by regulating the flow of heat transfer fluid. Its importance stems from the role it plays in optimizing the system’s efficiency and ensuring effective heat collection. By controlling fluid circulation, the valve helps maintain the system’s desired temperature, preventing overheating or inefficient heat transfer. Without a properly functioning solar dark valve, systems risk diminished performance and increased energy expenses, making regular maintenance imperative.

HOW DO I IDENTIFY A BROKEN SOLAR DARK VALVE?

Several indicators suggest a malfunctioning solar dark valve. Look for visible leaks around the valve mounting points, unusual noises during operation, or erratic temperature readings from solar thermal panels. Continuous monitoring of these signs is essential, as early intervention can prevent further damage or system inefficiencies. Utilizing a pressure gauge to check for drops can also indicate blockages or issues within the valve, assisting in accurate diagnostics.

IS IT SAFE FOR ME TO REPLACE THE VALVE MYSELF?

Replacing a solar dark valve can be a safe endeavor for those with the requisite skills and tools. However, it is advisable to have a fundamental understanding of plumbing and solar thermal systems. Familiarity with basic safety practices is critical, including wearing proper safety gear and ensuring that the system is fully de-pressurized before attempting any work. If uncertainties arise, consulting with a professional technician is highly recommended to avoid potential hazards or installation errors.

Replacing a broken solar dark valve involves key phases from recognizing symptoms to executing the replacement and testing for proper functionality. Each step demands keen attention to detail and a comprehensive understanding of the system. Initiating the process begins with accurately identifying issues tied to valve performance. Gathering necessary tools facilitates a more seamless transition throughout the replacement procedure. Precise actions during removal and installation are crucial to prevent potential mishaps. Testing the entire system post-installation ensures that efficacy is restored and any concerns are promptly identified. This meticulous approach ultimately promotes a longer lifespan for a solar heating system. While do-it-yourself replacements can be accomplished, consulting a professional can provide additional reassurance and expertise, enhancing overall safety and effectiveness. Ultimately, maintaining awareness of the solar dark valve’s status ensures optimized performance and energy efficiency for years to come.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-replace-the-solar-dark-valve-if-it-is-broken/