To effectively replace the solar check valve, one must undertake a meticulous process that guarantees ideal functioning of the solar heating system. 1. Identify the appropriate tools and materials, 2. Shut off all power and fluid flow, 3. Remove the existing check valve, 4. Install the new check valve, and 5. Test the system for leaks and functionality. Each of these steps is crucial for ensuring not only the longevity of the new valve but also the overall efficiency of the system.

1. IDENTIFYING THE NECESSARY TOOLS AND MATERIALS

To initiate the process of replacing a solar check valve, having the right tools and materials is imperative. Those planning to undertake this task should gather specific items such as pipe wrenches, screwdrivers, plumber’s tape, and potentially replacement fittings, depending on the existing system configuration. The check valve itself should also be of a suitable type and size for the solar heating system in question. Understanding the specific valve type—whether it’s a spring-loaded or diaphragm type—is critical, as this will influence the selection of the replacement part.

It’s prudent to conduct research regarding the specifications of the check valve based on manufacturer’s guidelines. The selection of materials can spell the difference between a durable system and recurrent leaks. Usage of high-quality valves and fittings will ensure a harmonious fit and reduce the risk of future complications. Preparing a work area that is clean and free from obstructions further enhances efficiency during the replacement process. Organizing tools and materials ahead of time can save valuable hours and ensure that everything is easily accessible during the operation.

2. SHUTTING OFF ALL POWER AND FLUID FLOW

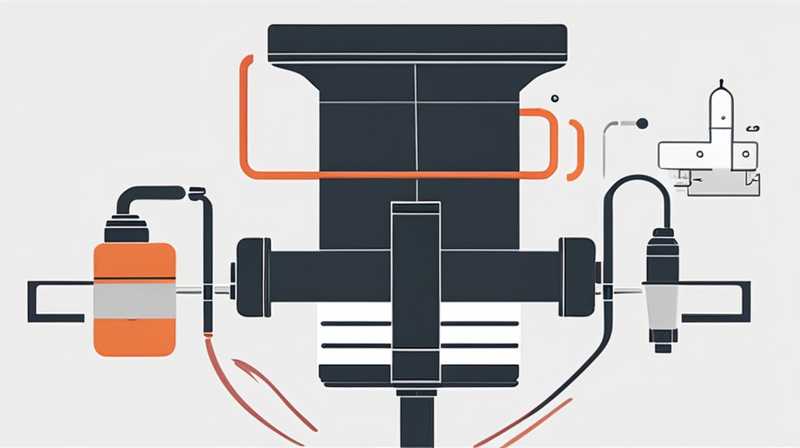

Prior to beginning any physical work on the solar check valve replacement, it is crucial to ensure that all power sources to the solar heating system are turned off. This not only safeguards the individual performing the replacement but also protects the integrity of the solar components. Following the disconnection of power, one should proceed to isolate the fluid flow. This is typically achieved by closing the appropriate valves connected to the solar circulating system.

Neglecting these safety measures can result in hazardous situations, including potential burns from hot water or exposure to electrical components. Another common mistake during this initial phase is to overlook the need to relieve pressure within the system. A controlled release of system pressure is necessary through strategically opening vents or valves. This step effectively reduces the risk of sprays or leaks when removing the check valve. Properly executing these precautions will create a safe working environment conducive to the rest of the valve replacement process.

3. REMOVING THE EXISTING CHECK VALVE

Once a secure environment is established, the subsequent activity involves the careful removal of the existing check valve. This requires using appropriate tools, such as pipe wrenches or pliers, to loosen any connectors or fittings without damaging adjacent piping. It is vital to remember that some systems may have been in place for several years, and corrosion or accumulated mineral deposits can affect the ease of removal. Employing penetrating oils can facilitate loosening stubborn connections.

Make sure to have a container ready to catch any remaining fluid from the system as the old check valve is disconnected. Inspecting the old valve at this stage can provide insight into why it failed, whether due to wear, blocking debris, or other unforeseen issues. It is essential to take note of the orientation and configuration of the existing valve to replicate it accurately with the new component. Doing so will ensure that flow direction is maintained and that there are no operational issues once the new valve is installed.

4. INSTALLING THE NEW CHECK VALVE

With the old valve successfully removed, the next step involves installing the new solar check valve. First, ensure the new valve is clean and free of debris. Using plumber’s tape on the threads of fittings where applicable is advisable to prevent leaks. Start by aligning the new valve in the exact orientation of the previous one, as this dictates the flow direction and operational effectiveness.

Secure the valve by tightening the fittings appropriately, but avoid over-tightening. Over-tightening can risk damaging the valve, leading to an improper seal. Proper connection is crucial for ensuring the system functions optimally without any leaks. After installation, it is important to double-check all connections and fittings to ensure a smooth operation. Ensuring that this component is aligned correctly is fundamental to achieving optimal solar system efficiency.

5. TESTING THE SYSTEM FOR LEAKS AND FUNCTIONALITY

Upon completion of the installation, the testing phase is critical to confirm that the new solar check valve is operating correctly. First, restore power to the solar heating system and verify that fluid flow resumes as expected. Observing the system for leaks at the connection points is essential during this initial testing. A minor water leak can indicate improper fitting, providing an opportunity to tighten or reseal connections before further evaluation.

It may also be beneficial to monitor system performance under different operating conditions, ensuring the check valve opens and closes effectively according to system pressures. Capturing baseline functionality allows for future comparisons, enhancing overall system maintenance. Following testing, document installation details, including valve type and any observations during performance checks, which can be valuable for future maintenance or troubleshooting.

FREQUENTLY ASKED QUESTIONS

WHAT SIGNS INDICATE A FAULTY SOLAR CHECK VALVE?

Potential indicators of a defective solar check valve can manifest through various symptoms. One notable sign is the inconsistent flow of fluid within the system. If the pump is constantly running yet the fluid does not circulate correctly, this points towards a check valve failure. Furthermore, an unusual increase in pressure within the system can indicate that the check valve is not functioning adequately, potentially leading to leaks or other structural damage.

A deeper investigation is warranted if there are audible sounds of water hammer, a symptom of rapid fluctuations in water flow indicative of an improperly functioning valve. Additionally, visible leaks surrounding the valve area represent a critical failure point. Regular maintenance and vigilance can ensure immediate identification of such issues, facilitating timely repairs.

HOW OFTEN SHOULD SOLAR CHECK VALVES BE REPLACED?

The frequency of solar check valve replacements varies significantly depending on several factors. Generally, a well-maintained solar system might require replacement every 5 to 10 years. However, several variables, such as water quality, system pressure, and thermal cycling, can impact the valve’s lifespan. If the system has a high level of mineral content or significant fluctuations in water temperature and pressure, more frequent inspections may be necessary.

Conducting routine maintenance checks allows for identifying wear and tear before significant failure occurs. Notably, seasonal inspections are particularly critical in regions with harsh winters, as prolonged exposure to freezing temperatures can compromise valve integrity. Documenting the replacement history of the check valve will help set a pattern for proactive maintenance planning.

CAN I REPLACE THE SOLAR CHECK VALVE MYSELF OR HIRE A PROFESSIONAL?

The decision between self-replacement and hiring a professional largely depends on one’s expertise and comfort level with plumbing tasks. For those with adequate experience in working with plumbing or solar systems, replacing the check valve might be a feasible DIY project. Understanding essential tools and procedures is essential, as is adhering to safety protocols during the process.

However, individuals lacking experience or those who have complicated systems may find it best to hire a qualified professional. A technician’s expertise ensures not only proper installation but may also uncover other underlying issues that could impact system performance. Weighing the costs against potential risks of doing it oneself provides clarity in making this decision.

FINAL REMARKS

Successfully executing the replacement of a solar check valve involves several meticulous steps that ensure overall system functionality and reliability. Preparing adequately by gathering necessary tools and following safety protocols can mitigate risks associated with the process. Thorough inspections during removal and installation phases can preempt future complications. By understanding system dynamics and ensuring proper valve orientation, an efficient and effective understanding of the task emerges, ensuring the solar heating system remains in optimal condition. Investing effort into this task not only fortifies the reliability of the solar system but also prolongs its life expectancy and efficiency, leading to sustainable and cost-effective energy use. Homeowners gain the advantage of controlling their energy management systems more efficiently and economically through such preventive measures and thoughtful engagements with system components.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-replace-the-solar-check-valve/