To replace the sealing ring of a solar jacking pipe, one must first gather the necessary tools and materials, then proceed with a systematic approach. 1. Ensure safety precautions are in place, 2. Disconnect any power sources, 3. Remove the existing sealing ring, 4. Clean the surface before installation, 5. Install the new sealing ring, 6. Test the integrity of the installation. The process requires attention to detail and a clear understanding of how the sealing ring functions within the solar jacking pipe system. Particularly, ensuring a proper seal is essential to prevent leaks and maintain the efficiency of the solar power system. This article will provide a comprehensive overview of the steps involved and the considerations to keep in mind during the replacement process.

1. UNDERSTANDING THE ROLE OF SEALING RINGS

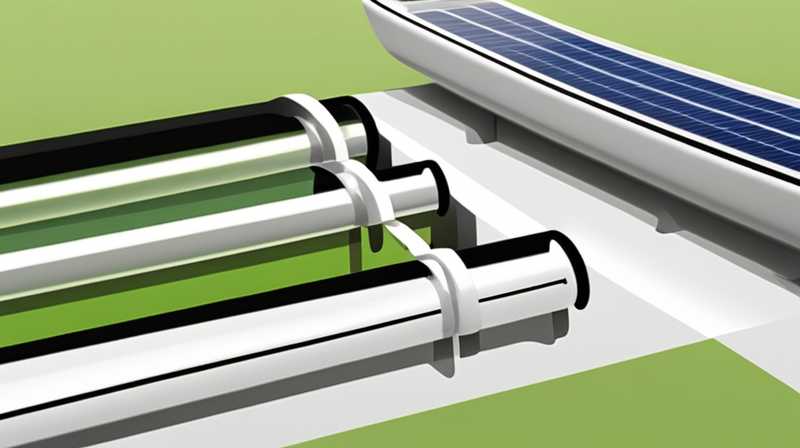

Sealing rings play a critical role in the integrity of any piping system, particularly in solar applications. They act as barriers to prevent leakage and ensure that the connections between different components of the solar jacking pipe remain airtight and fluid-tight. Sealing rings must be made from materials that can withstand both high temperatures and the chemical compositions of various fluids, which is essential for maintaining the efficiency of the solar energy system.

In solar jacking pipes, the sealing ring not only contributes to energy efficiency but also safeguards the entire installation from environmental hazards. If the sealing ring fails, the risk of leaks increases, potentially leading to significant operational issues and energy losses. Additionally, understanding the differences between various types of sealing rings — such as O-rings and gasket seals — can inform a more effective replacement strategy.

2. GATHERING THE NECESSARY TOOLS AND MATERIALS

Before embarking on the replacement of the sealing ring, it is imperative to collect the appropriate tools and materials, ensuring a smooth and efficient process. Essential tools may include a wrench, screwdriver, utility knife, and cleaning supplies, along with personal protective equipment like gloves and goggles.

The selection of the new sealing ring is equally significant. It is crucial to choose a ring that is compatible with the specifications of the solar jacking pipe. Researching the correct material type, such as silicone or EPDM rubber, provides a foundation for successful installation. Utilizing the wrong sealing material can result in early failure, leading to unnecessary maintenance and potential system shutdowns.

3. SAFETY PRECAUTIONS

Prior to starting any work, implementing safety measures is non-negotiable. Ensuring that the solar power system is completely powered down is vital to avoid electric shock or equipment damage. Disconnecting power supplies and placing warning signs can prevent unintended activation while conducting repairs.

Wearing appropriate personal protection, such as gloves and eyewear, is essential to safeguard against potential hazards, including sharp tools and chemical exposure. Creating a clean and organized workspace also contributes to overall safety, as it minimizes the risk of accidents. Assessing and mitigating risks beforehand creates a more efficient working environment and fosters better focus on the task at hand.

4. REMOVING THE EXISTING SEALING RING

To initiate the replacement process, the first step involves carefully removing the existing sealing ring. Using a utility knife or screwdriver, the old ring can be pried away from the jacking pipe, taking care not to damage the pipe itself during the removal process. Any remnants of the old sealing material must be thoroughly cleaned to prepare for the new installation.

Attention should be given to any potential damage to surrounding components during removal, as this can complicate future repairs or installations. If necessary, consulting the manufacturer’s guidelines or seeking professional assistance can provide additional insights on effective removal techniques. Every detail during this step is crucial for the successful fitting of the new sealing ring.

5. CLEANING THE AREA FOR INSTALLATION

Once the old sealing ring has been removed, thoroughly cleaning the surface of the jacking pipe ensures a proper and secure fit for the new sealing ring. This cleaning process may involve using solvents or cleaning agents that are compatible with the materials involved, effectively removing debris and residue.

Failure to clean the surface adequately can lead to improper sealing, thus introducing the risk of future leaks or system inefficiencies. Effective cleaning not only aids in achieving a tighter fit but also prolongs the life of the new sealing ring. Comprehensive attention to cleanliness during this phase sets the stage for successful reinstallation.

6. INSTALLING THE NEW SEALING RING

With the area prepared, the next focus shifts to installing the new sealing ring. Careful placement of the sealing ring into the designated groove of the jacking pipe is crucial for ensuring the overall system’s integrity. It is essential to ensure that the ring is not twisted or pinched during installation, as this could affect its performance.

Using lubrication can facilitate easier installation, particularly in tight spaces. Engaging attentively during this step allows for a smooth setup, reducing the risk of potential future failures. After the ring is positioned correctly, the components can be reassembled, ensuring that all fittings are secure and aligned properly.

7. TESTING THE INTEGRITY OF THE INSTALLATION

Upon completing the installation of the new sealing ring, conducting thorough testing is vital to affirm the success of the operation. Reconnecting power and running the system allows for close monitoring of any leaks or malfunctions, confirming that the sealing ring is functioning as intended.

Visual inspections during this testing phase play an important role in identifying potential issues. Should any leaks be observed, immediate rectification is necessary to prevent further complications. This proactive approach not only guarantees the reliability of the newly installed sealing ring but also assures the long-term functionality of the solar jacking pipe system.

8. MAINTAINING AND MONITORING SEALING RINGS

In order to ensure longevity and peak performance of the sealing rings, consistent maintenance and monitoring should be practiced. Periodic checks and evaluations of the sealing ring’s condition can identify wear and tear before it leads to failure. Regular maintenance encourages proactive measures that offer greater control over potential issues that may arise.

Record-keeping of inspection intervals and findings assists in tracking the performance of the sealing rings over time. Creation of a maintenance schedule not only optimizes the operational efficiency of the equipment but also aids in budget planning for replacements or repairs. This forward-looking approach contributes to the sustainability of solar energy systems.

9. ENVIRONMENTAL CONSIDERATIONS

In the context of solar energy systems, it is also important to consider environmental impacts during the replacement process. Selecting sealing rings made from eco-friendly materials contributes to sustainable practices, minimizing ecological damage. Furthermore, disposing of old sealing rings and materials through responsible channels ensures compliance with environmental standards and legislation.

Adopting sustainable practices in maintenance and repair activities reflects a commitment to ecological responsibility, aligning with the core principles of renewable energy. This holistic approach enhances both the efficiency of individual systems and the broader environmental impact associated with solar energy.

FREQUENTLY ASKED QUESTIONS

WHAT COMMON SIGNS INDICATE A FAULTY SEALING RING?

A faulty sealing ring may present several visible indicators. One of the most common signs is leakage, which can manifest as drops of liquid around the joint where the sealing ring is located. Additionally, unusual odors or sounds during operation may indicate that the sealing ring is not performing correctly.

Another indication is the presence of air pockets or pressure loss in the system, which can significantly impact the efficiency of the solar jacking pipe. When performance begins to decline or when regular maintenance is conducted, inspecting the sealing rings for signs of wear and tear is essential. By being proactive and attentive to these signals, one can prevent more significant damage or inefficiencies in the system.

HOW OFTEN SHOULD SEALING RINGS BE REPLACED?

The frequency of replacing sealing rings can vary depending on several factors, such as the operating environment, the quality of the sealing materials used, and the overall operational conditions of the solar jacking pipe system. In general, it’s advisable to conduct monthly inspections, checking for signs of wear, leakage, and general condition of the sealing rings.

For standard maintenance, a replacement every few years is often sufficient. However, if the system operates in extreme conditions or experiences significant shifts in temperature or pressure, more frequent replacements may be necessary. Establishing a routine for monitoring and maintenance ultimately preserves the functionality of the entire solar energy system.

WHAT SHOULD I DO IF I ENCOUNTER A LEAK AFTER REPLACEMENT?

If a leak is detected after the replacement of a sealing ring, it is crucial to take immediate action to address the issue. First, power down and disconnect the solar system to ensure safety, preventing any risks during inspection. Next, conduct a visual examination to determine whether the sealing ring is properly seated and free from any damage or misalignment.

If the sealing ring appears to be compromised, reinstallation or replacement may be required. Using appropriate tools and methods will ensure that the new sealing ring is correctly positioned and secured. Keeping a record of the issues encountered may guide future maintenance and serve as a reference for identifying recurring problems.

Proper understanding and execution of the steps involved in replacing the sealing ring of solar jacking pipes are paramount in maintaining system efficiency and longevity. It is essential to remain vigilant and informed, as this will enhance the overall performance of solar energy systems while safeguarding against potential issues. Additionally, by adopting sustainable practices in maintenance, operators contribute positively to environmental stewardship through renewable energy applications. The careful monitoring, proactive maintenance strategies, and environmental considerations ultimately reflect the commitment towards achieving an efficient and resilient solar energy setup. This holistic approach ensures sustainability and extends the lifespan of vital components, fostering an environment that embraces both technological advancements and ecological preservation.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-replace-the-sealing-ring-of-solar-jacking-pipe/