To successfully replace the pressure relief valve on a solar energy system, key steps should be followed: 1. Understand the function of the pressure relief valve, 2. Determine the right replacement valve, 3. Prepare necessary tools for the task, 4. Follow safety protocols during the replacement process, 5. Test the system post-replacement for efficiency. The pressure relief valve is essential in maintaining the safety of the solar water heating system. It prevents overheating and overpressure scenarios, which can lead to system failures or hazardous situations. Determining the right replacement valve involves considering factors such as size, temperature rating, and compatibility with the solar system. Proper preparation helps in executing the replacement efficiently, ensuring that all tools and replacement parts are at hand. Adhering to safety protocols is crucial to avoid accidents while replacing the valve, and conducting thorough testing after the task guarantees that the system operates safely and effectively without any leaks or faults.

UNDERSTANDING THE PRESSURE RELIEF VALVE

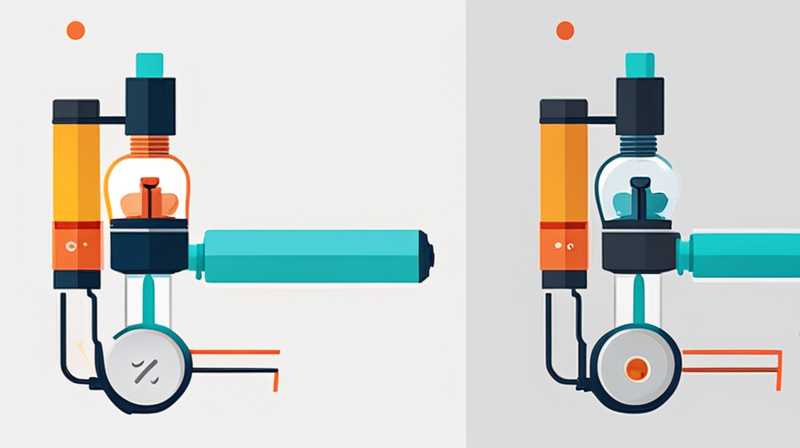

The pressure relief valve is an integral component within solar thermal systems. Serving as a safety mechanism, it prevents excessive pressure build-up, which can occur due to overheating of the system. This pressure build-up can lead to dangerous situations, such as bursting pipes or tank failures. Consequently, these valves are designed to release pressure when it reaches a specific threshold, thus protecting the entire solar system from damage.

Before proceeding with the replacement, it is crucial to analyze the specific function of the pressure relief valve in your solar energy setup. Understanding its operational parameters, such as the pressure rating and temperature tolerance, is fundamental. This information links directly to the safety mechanisms of your system and helps in selecting the correct replacement components. Additionally, comprehending the construction and working mechanism of the valve prepares you for any potential issues during the replacement process.

IDENTIFYING THE RIGHT REPLACEMENT VALVE

Replacing the pressure relief valve necessitates selecting an appropriate replacement that matches the specifications of the existing valve. Factors such as pressure rating, size, and compatibility with the fluid in the system must not be overlooked. Manufacturers provide various models, and specific parameters play a crucial role in ensuring the new valve operates correctly within the solar energy system.

Begin by referencing the original valve’s documentation, which should detail its specifications. It’s essential to evaluate compatibility with your solar system’s specific design and requirements. If the exact model isn’t available, consult with a professional or supplier who specializes in solar energy systems. They can recommend alternatives that maintain the functionality and safety standards of your installation.

GATHERING NECESSARY TOOLS

Preparation sets the tone for a successful valve replacement. Before starting, ensure to gather all essential tools, including pipe wrenches, screwdrivers, pliers, and a basin to catch any residual water. The right tools streamline the process and minimize the risks of damaging pipes or fittings during installation.

In addition to tools, consider having replacement parts on hand, such as gaskets or Teflon tape. These materials are vital for ensuring that there are no leaks once the new valve is in place. Proper preparation aids in executing the replacement smoothly, keeping downtime to a minimum.

EXECUTING SAFETY PROTOCOLS

Safety must remain a priority throughout the valve replacement process. Before beginning, ensure the solar system is powered down and cooled to avoid accidents. Drain the water from the system to minimize the risk of water spillage and damage. This step is crucial for both the safety of the installer and the integrity of the system.

Use appropriate personal protective equipment (PPE), including gloves and goggles, to shield yourself from potential injuries while handling tools and components. Understanding potential hazards is critical, especially since working with pressure systems requires heightened awareness of risks involved with pressurized water and heat. A safety-first approach not only protects the individual performing the work but also ensures the longevity and reliability of the solar system.

REMOVING THE OLD VALVE

To begin the removal process, locate the existing pressure relief valve. Using the appropriate tools, carefully unscrew the valve from its fittings. It’s advisable to do this slowly to prevent damaging the threads or surrounding pipes. If the valve has been in place for a long time, it may be stuck, necessitating a little extra force.

Once the valve is loosened, allow any remaining water to drain away into the basin prepared earlier. Thoroughly inspect the area for any rust, corrosion, or damage to the pipes. Addressing these issues before installing the new valve can prevent future complications and enhance the efficiency of your solar energy system.

INSTALLING THE REPLACEMENT VALVE

With the old valve removed, it is time to install the new pressure relief valve. Begin by ensuring the threads on both the pipe and valve are clean and free of debris. Applying Teflon tape to the threads enhances the seal and reduces the likelihood of leaks. Carefully screw the new valve into place, ensuring it is secured but avoiding overtightening which could damage the fittings.

After the valve is installed, it’s essential to double-check all connections. Make certain that everything is aligned properly and that there are no visible gaps between the valve and the pipe fittings. Any signs of misalignment could lead to pressure issues or leaks in the future.

TESTING THE SYSTEM POST-REPLACEMENT

Upon completing the installation, it is crucial to restore power and reintroduce water into the solar energy system to test the newly installed valve. Begin by slowly refilling the system, monitoring for any irregularities. Observing the system closely during this initial phase allows for the early detection of potential leaks or malfunctions.

After the system is filled, activate the solar panel system. Monitor the pressure relief valve closely during this tested phase; it should function correctly, releasing pressure only when necessary. If any issues arise during testing, it may be necessary to revisit the installation steps to ensure everything is properly aligned and secured.

MAINTAINING THE PRESSURE RELIEF VALVE

Regular maintenance of the pressure relief valve can significantly extend its lifespan and functionality. Routine inspections should be conducted to ensure the valve operates correctly and to identify any signs of wear that could signal a need for replacement. Keeping a schedule for these checks can enhance the reliability of your solar system.

In addition to periodic inspections, testing the valve’s function periodically is recommended. This can be done by briefly opening the valve to see if it releases water as expected. A functioning valve only needs minimal servicing to ensure continued effectiveness and safety.

FAQS

WHAT SIGNS INDICATE THAT A PRESSURE RELIEF VALVE SHOULD BE REPLACED?

There are several signs indicating a pressure relief valve may need replacement. Frequent leaks around the valve, no longer opens upon reaching the set pressure, or excessive sediment build-up could indicate failure. Over time, wear and tear can impair the valve’s function, leading to unsafe pressure levels.

If you notice any unusual popping sounds or pressure readings outside of a normal range, this could indicate that the valve is malfunctioning. Periodic inspections should be a part of your maintenance routine, ensuring any issues are caught early. In case of failure, consult a specialist to confirm whether a replacement is necessary and discuss the options available.

HOW OFTEN SHOULD A PRESSURE RELIEF VALVE BE REPLACED?

The replacement frequency of a pressure relief valve may vary based on usage and system demands. Typically, these valves have a lifespan of about five to ten years, but this depends on the conditions they operate under. Factors such as water quality, temperature, and system pressure influence the valve’s durability.

Routine inspections are crucial to determine the need for replacement. If signs of corrosion, cracks, or leaks are observed during these checks, it is advisable to replace the valve. Regular maintenance contributes to long-term performance and ensures user safety.

CAN I REPLACE THE VALVE MYSELF, OR SHOULD I HIRE A PROFESSIONAL?

Replacing a pressure relief valve can be accomplished by knowledgeable individuals with basic plumbing skills; however, hiring a professional is often advisable. A certified technician possesses the necessary expertise to manage potential complications effectively. They understand the intricate workings of solar energy systems, ensuring a proper replacement without jeopardizing safety.

If you choose to undertake the replacement, it is critical to follow all safety protocols and manufacturer guidelines. Understanding the system thoroughly helps in diagnosing issues and successfully executing the valve replacement. Proper documentation of your system and any changes made can be beneficial for future maintenance or repairs.

The replacement of a pressure relief valve in a solar energy system requires meticulous attention to detail, adherence to safety protocols, and thorough testing to ensure effectiveness. It is imperative that individuals undertaking this replacement be familiar with their solar systems and have an understanding of plumbing fundamentals. Selection of the correct replacement valve is essential for compatibility, and preparation with the right tools cannot be underestimated.

After successfully replacing the valve, conducting proper testing showcases the importance of monitoring system pressure. Catching discrepancies early can save costly repairs down the line. Regular inspections of both the valve and the overall system add another layer of security in ensuring efficient and safe operation of your solar energy system. With this knowledge and a proactive approach, users can significantly enhance the reliability and longevity of their solar installations.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-replace-the-pressure-relief-valve-of-solar-energy/