To replace the movable tee of a solar tube, follow these essential steps: 1. Begin by securely turning off the system, ensuring all components are no longer live, 2. Carefully detach the existing movable tee, taking note of the connections, 3. Install the new tee by reversing the disassembly process and re-establishing all necessary connections, 4. Finally, test the entire setup to confirm functionality and safety.

Replacing the movable tee of a solar tube may initially seem daunting; however, with the correct approach and methodology, the task can be accomplished efficiently. A movable tee is typically an integral component that facilitates the flow of heat transfer fluid within solar heating systems. Given its function, a malfunctioning or damaged tee can impede performance and lead to inefficiencies. As such, understanding the replacement process ensures consistent service and optimal operational capacity of solar tubes.

1. UNDERSTANDING SOLAR TUBE OPERATION

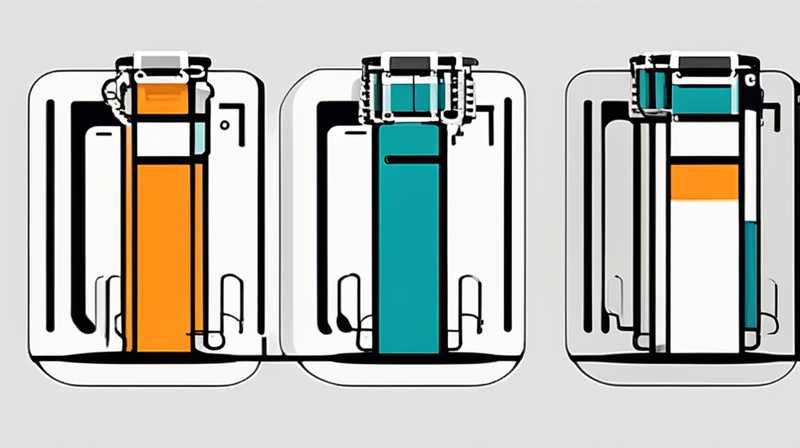

Solar tubes operate using the principles of thermodynamics and solar radiation. They consist of a sealed glass tube, a vacuum between layers, and absorptive coatings. The primary function is to collect and convert sunlight into thermal energy, which is then transferred to a fluid medium to heat water or air.

The movable tee integrates with the system to redirect the fluid appropriately, assisting in maintaining an efficient and balanced thermal movement. Essentially, in fluid mechanics, this ensures that the highest amount of heat collects and flows to where it is most required. Over time, wear and tear on these components can occur, necessitating a replacement to restore optimal functionality. Understanding the mechanics at play will aid in identifying when repair or replacement is necessary.

2. GATHERING NECESSARY TOOLS AND MATERIALS

Before delving into the replacement process, gathering all required tools and materials is paramount. Commonly needed items include a wrench set, screwdrivers, a replacement movable tee compatible with your specific solar tube model, sealant or plumber’s tape, and safety gear such as gloves and goggles.

Each tool serves an important function; wrenches are utilized to loosen and tighten fittings, while screwdrivers assist in detaching any screws that may secure the tee. Ensuring that all materials are organized beforehand minimizes the risk of losing focus or encountering interruptions during the procedure. Furthermore, opting for high-quality replacements ensures durability, prolonging the lifespan of the solar heating system and preventing future failures.

3. SAFETY PRECAUTIONS AND DISCONNECTING THE SYSTEM

Prior to initiating any repair actions, it is crucial to turn off the solar heating system completely. This involves disconnecting power sources, checking for any remaining pressure in the system, and ensuring that no heat transfer fluid is actively circulating. Safety precautions cannot be overstated, as working with pressurized or heated components can pose significant hazards if not approached with care.

Once the system is secure, proceed to identify all areas connected to the movable tee. Meticulously examine the joint connections — if these are soldered or threaded, ensure you have the appropriate tools to facilitate detachment. Documenting the original configuration through photographs or sketches can serve as a valuable reference during reinstallation. Taking this time to emphasize safety and structural integrity lays the groundwork for a successful repair.

4. REMOVING THE EXISTING MOVABLE TEE

Engaging in the removal of the existing movable tee requires a careful and methodical approach. After ensuring that the system is devoid of pressure and heat, utilize your tools to disengage any tightening mechanisms, screws or bolts that hold the tee in place. Depending on the age and condition, connections may have corroded, necessitating some additional force or the use of penetrating lubricant to facilitate the disassembly.

As the existing tee is being removed, pay close attention to any worn seals or gaskets that could indicate previous leaks. Existing components may provide insights into potential improvements or upgrades necessary for the new installation. This thorough examination not only assists in preventing issues upon reinstallation but also serves to enhance the overall performance of your solar tube system moving forward.

5. INSTALLING THE NEW MOVABLE TEE

With the old tee successfully removed, the next step involves the careful installation of the new movable tee. Begin by ensuring that all contact points are clean and debris-free to guarantee an effective seal when joining the new component. Applying a suitable sealant or plumber’s tape to threaded connections can add an extra layer of protection against future leaks.

Align the new tee’s fittings with the existing piping, following any reference documentation taken earlier to ensure accuracy in placement and orientation. After it is securely fastened, take care to replace any gaskets or seals previously removed, ensuring everything is tight. Proper installation is crucial, as any mistakes may lead to inefficiencies or exacerbated issues down the line.

6. TESTING THE COMPLETE SYSTEM

Following the successful installation of the movable tee, it becomes essential to assess the entire solar tube system for functionality and integrity. Begin by reconnecting the power supply and ensuring that any necessary valves are opened to allow the flow of the heat transfer fluid. By monitoring the system as it begins to operate, you can ascertain whether the new tee effectively redirects and manages the thermal flow as anticipated.

Observing the system for leaks at newly installed fittings or seams is crucial. In the case of any leaks, it may be necessary to revisit the installation process, adjusting tightness or replacing any faulty seals. Following these steps allows for a comprehensive examination that fortifies confidence in the functionality of the solar heating system and promotes longevity and efficiency.

7. MAINTAINING YOUR SOLAR TUBE SYSTEM

Once the replacement is complete and the system functions properly, it is wise to consider a regular maintenance schedule to uphold efficiency. Routine checks on seals, connections, and component condition can avert unexpected breakdowns. Additionally, maintaining the cleanliness of solar tubes and ensuring they are free of debris will maximize energy absorption from sunlight.

Regular system observation, ideally on a seasonal basis, can also help ensure that performance levels remain optimal. By replacing worn components timely and minimizing corrosion risks, the reliability of solar systems can be significantly enhanced. A proactive maintenance approach plays a key role in the long-term functionality of your solar tube system, underscoring the necessity of vigilance in system care.

8. THE IMPORTANCE OF PROFESSIONAL ASSISTANCE

In some situations, replacing the movable tee may present complications beyond the capabilities of a DIY approach. If considerable leaks or malfunctions persist, seeking the expertise of a certified technician may be prudent. Qualified professionals can offer insights based on experience and possess specialized tools that improve efficiency and safety during the replacement process.

Investing in professional assistance might seem costly upfront; however, preventing further damage or inefficient operation can save both time and money in the long run. Professionals can offer warranties or service guarantees, adding further value and reassurance of quality workmanship. Acknowledging the limits of one’s expertise is important; therefore, knowing when to seek help is crucial.

FREQUENTLY ASKED QUESTIONS

WHAT IS A MOVABLE TEE IN A SOLAR TUBE SYSTEM?

A movable tee in a solar tube system serves as a junction that directs the flow of heat transfer fluid between different sections of the system. This component is pivotal for ensuring that collected heat is efficiently transported to where it is needed, whether for heating water or other purposes. The movable aspect often allows for adjustments in flow dynamics, accommodating variations in temperature and system load.

Moreover, maintaining a movable tee’s integrity is crucial as it affects the overall efficiency of the solar heating system. If malfunctions occur, it can result in pressure build-ups, leaks, or uneven heating, leading to diminished performance. The replacement of a faulty or outdated movable tee becomes essential for restoring optimal operation, thus enhancing the system’s overall functionality.

HOW OFTEN SHOULD A MOVABLE TEE BE REPLACED?

The lifespan of a movable tee in a solar tube system can vary significantly based on factors such as material quality, environmental conditions, and the frequency of maintenance performed. Generally, it is advisable to inspect movable tees at least once a year. Signs of wear, corrosion, or leaks should prompt immediate evaluation and potential replacement.

In especially harsh conditions—exposed to extreme temperatures or environmental factors—components may degrade more rapidly. Therefore, proactive assessments contribute to making informed decisions about replacement before total failure occurs. By replacing the movable tee prematurely, you can ensure continued efficiency and avoid costly interruptions in solar system operation.

CAN I REPLACE THE MOVABLE TEE MYSELF, OR SHOULD I HIRE A PROFESSIONAL?

While many homeowners may feel capable of undertaking a movable tee replacement, assessing personal skill levels is key. For those with background knowledge and the proper tools, performing the replacement can be a satisfactory endeavor. However, if unfamiliarity with plumbing systems exists or if complications arise, opting for professional assistance is a prudent choice.

Hiring a qualified technician offers peace of mind, ensuring that the job is done correctly and safely. Professionals possess the necessary tools and experience to quickly identify issues and address potential complications that may not be immediately apparent to the untrained eye. Although it involves an additional cost, the investment can prove advantageous, particularly for intricate systems or when extensive modifications are required.

The process of replacing the movable tee of a solar tube involves multiple steps that, when performed correctly, contribute to the longevity and efficacy of the entire solar heating system. By understanding the operational mechanics, gathering necessary tools, implementing strict safety protocols, and performing diligent testing post-installation, any technician or DIY enthusiast can ensure a seamless transition to a new component. Regular maintenance and monitoring can further enhance system performance, leading to energy savings and prolonged equipment life. For those less confident in their skills, seeking professional assistance remains a sound strategy to guarantee success.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-replace-the-movable-tee-of-solar-tube/