To replace the elbow of a solar tube, one must follow a series of organized steps, ensuring safety and efficiency throughout the process. 1. Identify the proper materials, tools, and components needed for replacement, such as the new elbow, sealant, screws, and certain hand tools like screwdrivers and pliers. 2. During the replacement, ensure the solar tube system is deactivated and cooled down to prevent any injury. 3. Carefully detach the existing elbow, making sure to observe the original positioning and connections for proper installation of the new component. 4. Seal any joints properly to avoid leaks, ensuring that the system can effectively collect and transport solar energy. Pay special attention to the fittings, as a tight and secure connection is essential for the system’s performance. It is also advisable to consult with a professional if uncertainties arise during the process.

1. UNDERSTANDING SOLAR TUBE SYSTEMS

Solar tube systems play a crucial role in modern energy solutions, using tubular assemblies to capture and convert solar energy efficiently. They are designed to harness sunlight effectively, making them an ideal choice for residential and commercial applications. Understanding how these systems operate provides insight into the importance of each component within them, including the elbow.

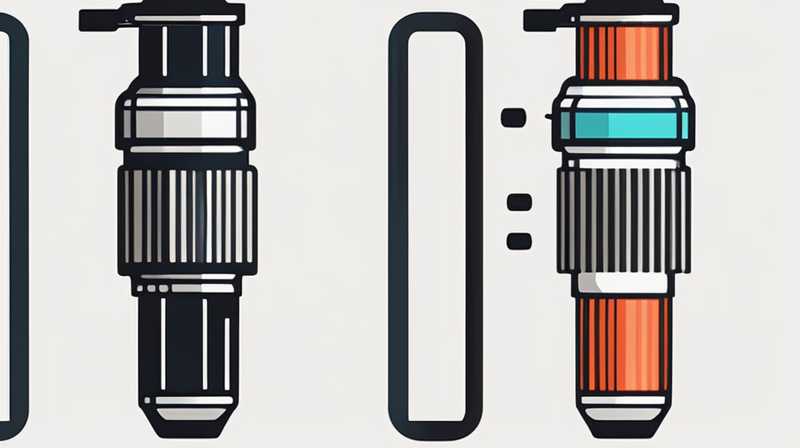

The elbow is a critical part of the solar tube, enabling the direction of sunlight into the collecting portion of the system. As the primary pathway for light, if the elbow becomes damaged or corroded, energy efficiency decreases significantly. Properly maintaining and replacing parts like elbows is essential to ensure the continuous performance of a solar energy system. The lifecycle of a solar tube is influenced by environmental factors, installation quality, and ongoing maintenance practices.

2. TOOLS AND MATERIALS REQUIRED FOR REPLACEMENT

To commence the replacement of the solar tube elbow, it is essential to gather the appropriate tools and materials. These include the new elbow, which must be compatible with the existing solar tube system. Other necessary items are screwdrivers, sealant, screws, and pliers. The quality of each component can affect the overall performance and longevity of the system, making it imperative to choose high-grade materials.

Before initiating the replacement, it’s beneficial to assess the existing installation for any underlying issues. This assessment can help identify whether additional components might require attention. Ensuring all tools are ready and functional will facilitate a smoother replacement process, reducing the chances of errors and misalignments. Moreover, confirming that working conditions are safe and accessible will enhance overall productivity during the task.

3. SAFETY PRECAUTIONS DURING REPLACEMENT

Implementing safety precautions is vital when working with solar tube systems. Electricity and heat are potential hazards that can lead to serious injuries, so deactivating the solar system is a must. Additionally, safety gear such as gloves, goggles, and hard hats might be necessary to prevent accidents during the process. It is essential to ensure that the surrounding area is clear of any obstructions to guarantee ease of movement.

The work environment should be stable, particularly if scaffolding or ladders are required to access higher installations. Also, having a reliable communication system in place, such as a mobile phone for emergencies, can be life-saving. By prioritizing safety measures, one can focus on executing the replacement flawlessly without distractions that may arise from potential hazards.

4. REMOVING THE OLD ELBOW

Removing the old elbow is a significant step in the replacement process. Begin by disconnecting any attachments, such as screws or brackets, securing the elbow to the solar tube assembly. Cautious detachment is necessary to avoid damaging adjacent components during removal. Observing the positioning and orientation of the old elbow can aid in correctly installing the new piece.

During removal, check for any signs of corrosion or damage in the surrounding fittings that may also require attention. Allowing time for thorough inspection will enhance the reliability of the overall system once the new elbow is installed. Properly documenting the state of everything during removal offers insight into future maintenance needs.

5. INSTALLING THE NEW ELBOW

Once the old elbow is entirely removed, it is time to install the new elbow. Begin by ensuring that the new component is clean and free from any obstructions. Accurately aligning the elbow with the existing structure is vital to maintaining the functionality and efficiency of the solar tube system. Secure the elbow initially with hand-tightened screws before using tools for final tightening to avoid any twists or misalignments.

After the elbow is fitted, ample amounts of sealant should be applied to all joints and connections. This step is critical to prevent leaks, ensuring that solar energy remains effectively redirected into the system. Allow adequate time for sealant drying based on the manufacturer’s instructions to ensure a strong bond before reactivating the solar system.

6. TESTING THE NEW INSTALLATION

Testing the new installation is crucial to confirm that the elbow functions as intended. After the system is reactivated, monitor the output for any irregularities that may indicate improperly sealed joints or misalignments. This phase often includes checking for proper light intake and ensuring that the overall efficiency aligns with expected performance levels.

In addition to monitoring performance, it is important to conduct regular inspections post-installation to identify any potential issues early on. Establishing a routine maintenance schedule will help prolong the life of the solar tube system and maintain optimal energy collection rates.

7. POTENTIAL ISSUES DURING REPLACEMENT

Despite careful planning, unforeseen issues may surface during the elbow replacement process. One common concern is discovering additional damage, necessitating further repairs, which can extend the timeframe for completion. Managing these complications requires adaptability, as well as readiness to procure additional parts promptly.

Another issue might be sizing compatibility; if the new elbow does not match the existing tubing dimensions, further modifications will be necessary. This emphasizes the importance of selecting the correct parts prior to the commencement of work. It is advisable to keep all original parts for reference during the installation process.

8. ENVIRONMENTAL CONSIDERATIONS

When replacing solar tube components, it’s beneficial to consider the environmental impact of decisions made throughout the process. Recycling old parts and ensuring proper disposal of materials contribute to sustainability efforts. Additionally, selecting eco-friendly materials for replacements can significantly reduce one’s carbon footprint and enhance the overall environmental integrity of the solar system.

Selecting environmentally sound practices during the elbow replacement can provide long-term benefits. By prioritizing sustainable options, individuals contribute positively to their surrounding ecosystems, helping to ensure cleaner energy use in the long run.

9. CONTINUING MAINTENANCE TIPS POST-REPLACEMENT

Following the elbow replacement, ongoing maintenance becomes increasingly crucial to maximizing system efficiency. Regularly scheduled inspections can prevent minor issues from escalating into major complications, ensuring peak performance. This can involve checking for any leaks, misalignments, or component wear, as well as testing overall energy output.

Staying informed about the latest advancements in solar technology allows one to adapt the system further as new, more effective components become available. Periodic professional assessments can yield valuable insights, ultimately contributing to longevity and enhanced energy collection. Ultimately, this proactive approach is essential for maintaining efficiency and extending the life of solar tube installations.

FAQs

WHAT ARE THE SIGNS THAT THE ELBOW OF A SOLAR TUBE NEEDS REPLACEMENT?

Identifying the signs that an elbow requires replacement is vital to ensure system performance. The most common indicators include reduced energy output, visible damage or corrosion on the elbow, and leaks near the joint areas. If the solar tube system demonstrates a sudden drop in efficiency or unusual temperature fluctuations, it may hint at an obstruction or malfunction within the plumbing of the system.

It is prudent to assess the elbow periodically, even outside of a complete system check, since a visually impaired inspection can overlook crucial elements. Observing mounting hardware for signs of rust or wear can serve as an early warning sign. Inspections should involve checking connections, confirming there is no buildup of debris that could block sunlight intake or energy transportation. Addressing issues early can save extensive costs over time while maintaining optimal functioning.

HOW LONG DOES IT TAKE TO REPLACE A SOLAR TUBE ELBOW?

The duration for replacing a solar tube elbow can vary significantly depending on several factors, such as the complexity of the system design, personal skill levels, and availability of tools and materials. On average, an elbow replacement may take anywhere from 2 to 4 hours for a proficient individual who has all resources readily available.

If complications like additional damage or incompatible sizing present themselves during the installation, the time frame for completion can be greatly extended. It’s essential to allow for extra time, especially if unfamiliar with solar tube mechanics. Initiating the project with a comprehensive plan, including contingency measures for unexpected issues, can streamline the process. Always allocate reasonable time for job completion instead of hurrying through, which may lead to further complications.

CAN I PERFORM THE REPLACEMENT MYSELF, OR SHOULD I HIRE A PROFESSIONAL?

Deciding whether to undertake the elbow replacement as a DIY project or hire a professional depends on several important factors, such as personal skill levels, available tools, and comfort with mechanical tasks. For individuals with experience in home repairs or mechanical components, handling the replacement may be feasible and rewarding.

However, safety should always be a priority. If uncertainty regarding the installation process exists or if more complex system characteristics are present, hiring a professional could effectively mitigate risks and ensure proper installation. Professionals not only bring expertise but also have access to specialized tools, which can enhance the quality of the replacement. Investing in professional services can ultimately provide peace of mind, confirming that the system operates optimally and efficiently for years to come.

The replacement of the solar tube elbow is an intricate task that requires careful planning, quality assessments, and informed decisions to achieve favorable results. Engaging the right components and employing a thorough approach ensures restored functionality and longevity. Throughout this entire process, prioritizing safety and proper installation practices is non-negotiable. Regular inspections after replacement further enhance the system’s performance and can offset potential issues. Moreover, considering environmental impacts adds another layer of responsibility, contributing to sustainable energy use in the long haul. With optimal methods and practices, one can not only replace the elbow efficiently but also maintain superior functionality in their solar energy systems, leading to continued energy savings and a reduced carbon footprint.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-replace-the-elbow-of-solar-tube/