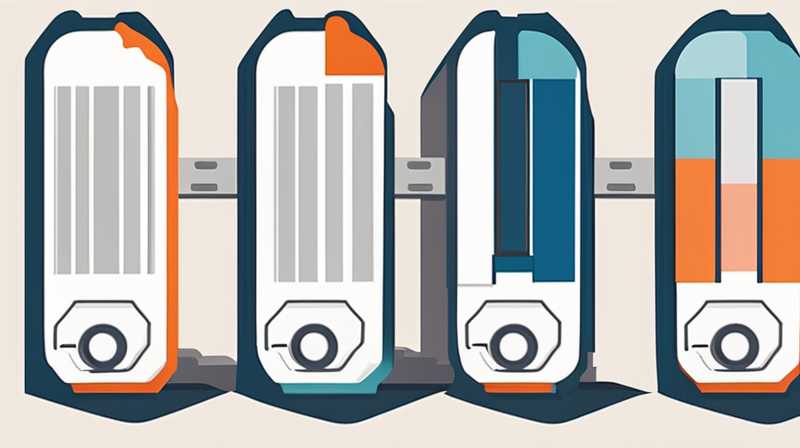

To replace the four valves of solar panels, specific procedures must be followed. 1. Begin by gathering the necessary tools and equipment, including safety gear and new valves, ensuring all materials are compatible with your solar panel system. 2. Next, ensure the solar panel system is completely powered down and isolated from any electrical sources to prevent accidents or electrical shocks. 3. Once safe, remove any coverings or insulation around the valves that need replacement, allowing for easy access. 4. Carefully detach the old valves by unscrewing or unclipping them, taking note of their configuration for accurate installation of the new components. 5. Install the new valves by reversing the removal process and ensuring that all connections are tight and secure. Taking the time to ensure proper sealing and alignment will prevent leaks. 6. Finally, restore the system’s power, conduct thorough testing to ensure everything is functioning correctly, and monitor the system for any discrepancies following the installation.

1. UNDERSTANDING THE VALVES’ ROLE IN SOLAR PANELS

Solar panels operate by converting sunlight into electricity, but the functionality of the entire system relies on various components, including valves. Valves play a critical role in fluid management within solar thermal systems, controlling the flow of heat transfer fluids such as water or antifreeze. These fluids circulate through the solar collectors and transfer captured heat to storage tanks or circulation pumps. Valves regulate pressure and flow within the system, providing essential control over energy efficiency.

The maintenance and replacement of these valves are paramount, as worn or malfunctioning valves can lead to leaks, loss of fluid, diminished efficiency, and, ultimately, system failure. Understanding how valves operate becomes crucial for solar panel owners or technicians looking to maintain or troubleshoot their systems effectively. Recognizing potential signs of valve wear, such as unusual noises or drops in system performance, allows for timely diagnostics to mitigate larger issues. Furthermore, familiarity with plumbing systems is necessary to enhance the understanding of the interdependent mechanisms of solar energy systems.

2. PREPARATION FOR VALVE REPLACEMENT

Prior to undertaking any maintenance or replacements of valves, careful preparation must take place. Identifying the type of valves used in your specific solar panel setup is crucial. This identifies the required specifications for compatible replacement parts, as not all systems utilize the same type. Ensuring the correct valve type will help avoid any potential mismatches that could lead to leaks or further faults down the road. When researching valve types, also consider the pressure and temperature ratings to ensure that they align with the operational parameters of your solar panels.

It is equally important to assemble the right tools before commencing replacement activities. Commonly needed tools include wrenches, screwdrivers, Teflon tape, and safety gear like gloves and goggles. Additionally, having replacement valves on hand prior to starting the process will save time and ensure efficiency during the replacement procedure. Creating a workspace that is organized and free of clutter will facilitate smoother sessions when detaching and securing valves, gracefully avoiding any unwanted accidents or misplacements of parts.

3. SAFETY MEASURES DURING REPLACEMENT

Engaging in solar panel maintenance necessitates a strong emphasis on safety. First, always ensure that the solar panel system is completely isolated from power sources. Disconnection from the electrical supply reduces the risk of electric shock during valve handling and maintenance. Also, assess the physical conditions around the solar panel installations to ensure there are no hazards, such as loose debris or sharp objects that might pose risks during work.

Furthermore, using personal protective equipment (PPE) is an essential part of ensuring safety during valve replacements. Consider wearing safety goggles, gloves, and steel-toed shoes, as these items protect against fluids, sharp parts, and potential falling tools. In case of encountering old, rusty valves or ejecting debris, adequate safety measures will reduce the chances of sustaining injuries. Ensuring thorough knowledge of the valve replacement process also encompasses awareness of potential hazards unique to the solar energy systems, such as hot components from heat transfer fluids, which could cause burns.

4. STEP-BY-STEP INSTRUCTIONS FOR VALVE REPLACEMENT

To replace the four valves of a solar panel system efficiently, follow a structured approach. Begin with powering off the system by disconnecting power sources and shutting down any related components. Next, allow the system to cool, particularly in solar thermal setups where fluid temperatures may pose hazards. By ensuring the components are cool and safe to handle, unnecessary risks can be mitigated.

Following safety checks, access the valves by removing any protective coverings or insulation as required. Take special care in documenting the configuration of existing pipes and tubes connected to the valves, as this can aid in the proper installation of new ones. Utilizing a wrench, carefully unscrew each valve, and avoid excessive force that may damage surrounding components or pipes. Place old valves aside and prepare to install the new components, ensuring the use of Teflon tape or appropriate sealing methods for effective sealing.

After securely fastening the new valves into place, restore coverings or insulation around the area to safeguard against environmental damage. Once the installation is complete, power the system back on and conduct a thorough functional test. Check for leaks around installed valves and evaluate overall performance metrics, such as temperature and flow rates, to ensure the system is operating optimally.

5. MONITORING AND MAINTENANCE POST-REPLACEMENT

Upon successful replacement and trial operations of the new valves, monitoring the system is imperative to ensure sustained efficiency. Continued observation allows for early detection of any anomalies that may arise, such as unexpected temperature fluctuations or irregular flow rates. Addressing any discovered issues promptly can significantly enhance the longevity of the entire solar energy system.

Scheduled periodic maintenance checks further bolster system reliability. Consider setting specific intervals, e.g., quarterly or biannually, to review valve conditions and overall system performance. Pay attention to cleaning components, removing any debris, and checking for signs of wear that may occur over time. Properly maintained systems not only perform better but also provide substantial energy savings in the long term.

Furthermore, keeping detailed logs of any maintenance performed, including dates, replacement parts used, and any observations noted during follow-ups, will assist in future repairs or replacements. In addition, possession of thorough documentation can facilitate easier troubleshooting should any issues arise with the solar panel system in the future.

FREQUENTLY ASKED QUESTIONS

WHAT SIGNS INDICATE VALVE REPLACEMENT IS NECESSARY?

Certain symptoms can signal the need for valve replacement within a solar panel system. Common indicators include visible leaks around valves, fluctuating system pressures, decreased system efficiency, or any unusual noises emanating from the components. If any of these issues arise, consulting a professional is advised to prevent exacerbating any underlying problems. Regular monitoring also plays a key role in early identification, so periodic system evaluations should be conducted to maximize the lifespan of the solar energy configuration.

In addition to physical symptoms, monitoring performance metrics such as fluid temperatures and flow rates can help pinpoint malfunctioning valves. If a valve fails to maintain proper pressure or allows for excessive backflow, it may not contribute effectively to the overall system. Conducting preventative maintenance can facilitate early detection, allowing for replacements before significant downtime occurs or costly damages ensue.

HOW OFTEN SHOULD VALVES BE REPLACED IN SOLAR PANELS?

The frequency of valve replacement in solar panel systems can vary based on several factors, including the type of solar installation, the quality of valves initially installed, and environmental conditions surrounding the panels. Generally, valves may require inspection every two to three years, with replacements initiated when signs of significant wear manifest. Components in environments with high temperatures or excessive debris may necessitate more frequent evaluation due to accelerated wear conditions.

Understanding the specific system type is crucial, as solar thermal setups may experience different wear patterns compared to photovoltaic systems. For systems frequently subject to extreme weather conditions or heavy usage, an annual inspection could be warranted to proactively monitor valve status. Keeping a maintenance schedule aligned with manufacturer recommendations can optimize pool health and service life within the solar energy system.

CAN I PERFORM VALVE REPLACEMENT MYSELF OR HIRE A PROFESSIONAL?

The decision to perform valve replacement independently or opt for hiring a professional depends on individual skill sets and confidence in handling plumbing or technical components. Those with extensive experience in HVAC systems or plumbing may feel comfortable executing the valve replacement without professional help. In contrast, less experienced individuals are advised to consult with certified technicians possessing expertise in solar energy installations.

Hiring professionals provides several advantages, including assurance of compliance with industry standards, deeper diagnostic capabilities, and the avoidance of potential damage to system components. Should complications arise during the replacement process, having access to a skilled technician can significantly reduce the risk of longer-term issues. Furthermore, professional installation often includes warranties on the work performed, thus benefiting owners in terms of peace of mind and additional protection against faults post-replacement.

FINAL THOUGHTS ON VALVE REPLACEMENT IN SOLAR PANELS

Efficiency and longevity in solar energy systems hinge significantly on the proper functioning of valves. By proactively addressing maintenance and following systematic replacement procedures, owners can ensure that their solar panels operate at optimal performance levels. Each component, though small in scale, contributes vital aspects to the larger energy system.

Equipping oneself with knowledge about valve types, potential risks, and the steps required for replacement enhances overall proficiency in solar maintenance. Whether undertaking the task personally or engaging a knowledgeable technician, individuals can derive substantial benefits from understanding the mechanisms underpinning their solar energy systems. Regular assessments and attentiveness to the functionality of the entire assembly promote lasting efficiency, providing energy savings for years to come.

Moreover, cultivating a strategic approach to valve maintenance fosters not only reduced operational costs but also a commitment to sustainable practices. Engaging with expert resources and reviewing thresholds for performance can guide future endeavors in solar technology management. In navigating the complex world of solar energy systems, an emphasis on proactive upkeep and responsive care remains key for every responsible solar panel owner.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-replace-the-4-valves-of-solar-panel/