To effectively replace a solar insulation layer, individuals must follow a comprehensive approach that ensures optimal functionality and durability. 1. Assess the existing insulation, as this will identify whether complete removal is necessary. 2. Gather the appropriate materials, including the type of insulation best suited to the specific solar system. 3. Prepare the workspace, ensuring it is clean and safe for work. 4. Follow proper installation procedures, adhering to manufacturer guidelines to guarantee efficiency and longevity. Particularly important is the step involving the selection of suitable insulation material, which should consider factors such as climate, local regulations, and energy efficiency ratings. Using materials that meet or exceed these standards will enhance the insulation’s performance and effectiveness in harnessing solar energy.

1. UNDERSTANDING SOLAR INSULATION LAYERS

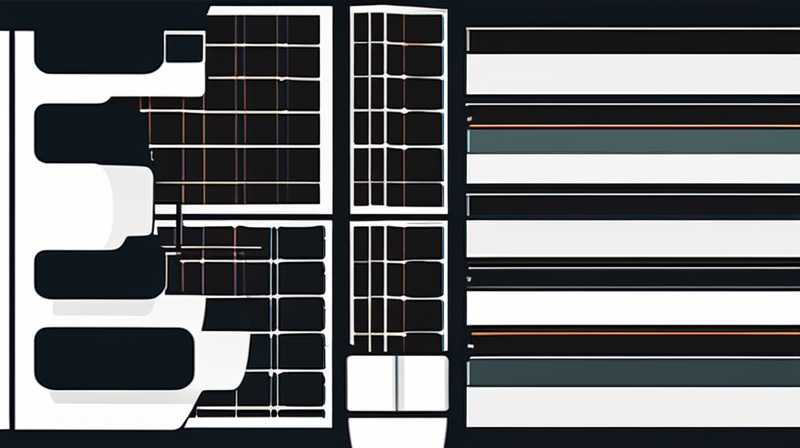

Insulation serves a critical role in solar energy systems, particularly when integrated with photovoltaic panels or solar heating systems. This protective layer regulates the temperature and enhances energy efficiency by minimizing heat loss or gain. Proper insulation contributes to the performance of solar systems, ensuring they operate at optimal levels throughout their lifespan. When addressing the question of replacing the insulation layer, it is essential to first understand its purpose and the materials involved.

The existing insulation tends to degrade over time due to exposure to environmental elements such as sunlight, moisture, and temperature variations. These factors can compromise its structural integrity, rendering it less effective in energy conservation. Regular assessments are advisable to determine whether the insulation layer is due for replacement. Additionally, understanding various insulation types, including fiberglass, foam board, or reflective insulation, can better inform the selection process for replacements.

2. INDOOR AND OUTDOOR INSULATION TYPES

When considering the replacements, it is vital to explore indoor and outdoor insulation types. Indoor insulation typically focuses on minimizing thermal bridging and protecting living spaces. Common indoor materials include fiberglass batts, loose-fill cellulose, and spray foam. Each option has unique properties influencing its thermal resistance (R-value) and installation complexity.

In contrast, outdoor insulation types must withstand harsher environments and weather conditions. Rigid foam boards and weather-resistant membranes often protect attic spaces and external walls. The efficacy of outdoor insulation relies on its resistance to moisture and wind, impacting its long-term performance. A comprehensive understanding of both these areas will aid in making informed decisions about suitable replacements.

3. ASSESSING THE CONDITION OF EXISTING INSULATION

Prior to initiating the replacement process, it is important to perform a thorough evaluation of the current insulation. This can be done visually or through advanced techniques such as infrared thermography. A careful inspection will help identify any signs of moisture damage, pests, or compaction that could jeopardize insulation effectiveness. Also, examining any gaps or missing sections will provide insight into whether repairs or total replacements are necessary.

An additional consideration in the assessment phase is energy performance. One may evaluate the insulation’s R-value, which measures its thermal resistance. Understanding the area’s climate and regulations can also guide this evaluation, ensuring that the new insulation adheres to building codes and maximizes energy efficiency. All of this information collectively influences the decision on whether the current layer should be replaced or merely augmented with additional insulation.

4. GATHERING THE RIGHT MATERIALS

Following the assessment, it’s time to gather suitable materials for replacement. Considerations include the desired R-value, roofing or wall system compatibility, and sustainability. For instance, those looking for long-term solutions may opt for materials like mineral wool or recycled cellulose, which offer excellent thermal performance while also being environmentally friendly.

Additionally, it is essential to have the correct tools on hand for the installation process. Standard tools might include a utility knife for cutting insulation to size, protective gear such as masks and goggles, and fasteners or adhesives depending on the material used. Investing in quality materials not only enhances performance but also contributes to the longevity and function of the solar insulation layer.

5. PREPARING THE WORKSPACE

Before beginning the installation process, taking the necessary safety precautions is critical. Ensuring that the workspace is organized and free from obstacles minimizes risks during replacement. This includes taking steps to protect existing systems and surfaces from potential damage. Depending on the solar installation type, employing additional safety measures like scaffolding or harnesses may be necessary when working at heights.

Moreover, ensuring proper temperature and weather conditions will facilitate a smoother installation process. Certain materials may require specific application environments to achieve optimal adhesion or performance, especially in roofing applications. By preparing the workspace appropriately, one can set the stage for a successful insulation replacement that meets all operational requirements.

6. INSTALLATION PROCEDURES AND TECHNIQUES

Executing the replacement requires adherence to precise installation procedures to ensure maximum efficiency. Following manufacturer instructions should always be the starting point of the process. For example, correctly measuring and cutting insulation materials minimizes waste and guarantees effective thermal performance.

Proper sealing is an equally vital element of the installation process. Utilizing tapes or sealants helps prevent air leaks, thereby enhancing insulation performance. This is particularly crucial in scenarios where insulation interacts with other building materials, as gaps can significantly diminish efficiency. Installing vapor barriers may also be necessary in areas prone to humidity or moisture, effectively protecting insulation from deleterious effects while maintaining performance.

7. POST-INSTALLATION CHECKS AND MAINTENANCE

Once the new solar insulation layer is in place, conducting post-installation checks is essential. Inspecting the installation for consistency, tightness, and proper sealing ensures that the insulation functions as intended. Special attention should also address any potential impacts on surrounding systems, including ventilation or ducts, which could interfere with the overall effectiveness of the solar energy system.

In the realm of maintenance, understanding the lifespan of various insulation materials will facilitate planning for future assessments or replacements. Establishing a schedule for inspections can ensure that the insulation remains intact and effective throughout its life cycle, thus maintaining energy efficiency. This proactive approach can mitigate potential issues down the line and ensure that the solar system continues to operate at optimal efficiency.

Frequently Asked Questions

1. HOW OFTEN SHOULD SOLAR INSULATION BE REPLACED?

Solar insulation replacement timelines vary depending on the materials used, environmental conditions, and local climate. Generally, it is advisable to evaluate insulation every 5 to 10 years. Signs of wear may include visible moisture damage, pest infestations, or reduced thermal performance as indicated by energy bills. By maintaining a proactive inspection routine, one can ensure that the insulation remains effective and contributes optimally to energy efficiency over time.

2. WHAT ARE THE BEST MATERIALS FOR SOLAR INSULATION REPLACEMENT?

Choosing the appropriate materials for solar insulation replacement depends on multiple factors, including climate, roofing style, budget, and sustainability preferences. Common options include fiberglass for its affordability, spray foam for superior air sealing, and cellulose for an eco-friendly choice with good thermal performance. Ultimately, the best material aligns with the unique requirements of the specific solar system and environmental conditions.

3. CAN I INSTALL SOLAR INSULATION MYSELF, OR SHOULD I HIRE A PROFESSIONAL?

While some individuals may have the skills to install solar insulation independently, hiring a professional is often the preferred route. Professionals bring valuable expertise in assessing current insulation conditions and selecting suitable materials while ensuring proper installation techniques are followed. This not only guarantees quality workmanship but also mitigates potential risks arising from improper installation. Cost considerations may factor into this decision, but the advantages of expert installation often outweigh do-it-yourself efforts.

In sum, replacing a solar insulation layer is a multifaceted process that requires careful consideration and execution. Thorough assessments of existing conditions can guide material selection, ensuring that the correct type of insulation is chosen. Proper installation practices and safety measures are essential to achieve an efficient outcome, as is conducting post-installation checks and maintenance according to a reliable schedule. By focusing on these key elements, individuals can maintain a high-performing solar energy system that is well insulated and capable of delivering optimal energy efficiency over its lifespan. Through ongoing diligence in evaluating and upgrading insulation materials, homeowners can maximize the benefits derived from their solar systems, including reduced energy costs and enhanced environmental sustainability. Ultimately, this journey not only contributes to personal savings but also supports a broader commitment to renewable energy, making a positive impact on the environment.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-replace-solar-insulation-layer/