1. Replacing a solar direct valve involves several steps that must be adhered to for optimal functionality. The process includes: 2. Properly identifying the existing direct valve and ensuring it is the correct type and size for replacement, 3. Safely draining any fluid or pressure in the solar system, 4. Detaching the old valve while being cautious of any remaining fluid that may leak. Detailed attention to these steps is essential for maintaining the efficiency and safety of the solar heating system.

INTRODUCTION TO SOLAR DIRECT VALVES

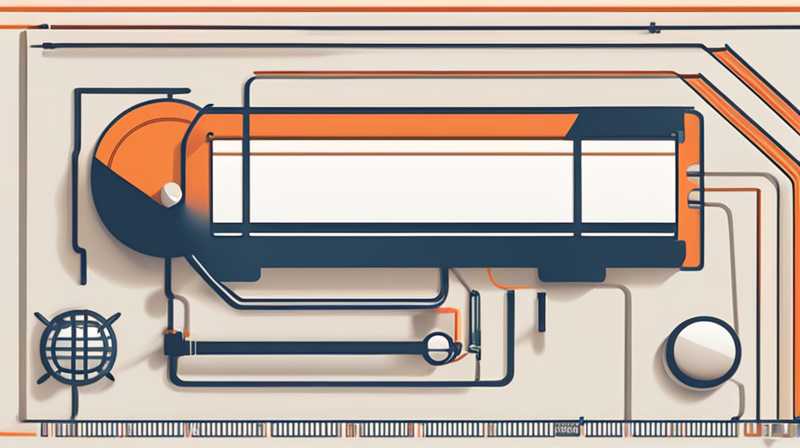

Solar heating systems are integral components in contemporary energy-efficient architectures. A solar direct valve is crucial for regulating the flow of heat transfer fluid within a solar thermal system. These valves manage the circulatory system, allowing heated fluids from solar collectors to transfer heat to storage tanks or directly to a heating network. Understanding how to effectively replace a solar direct valve is vital for maintaining system efficiency and prolonging the lifespan of solar heating systems.

The need for replacement may arise from wear and tear, leaks, or malfunctions in the heating system. To ensure ongoing performance, an understanding of the components involved is imperative. It is essential to know that improper handling or replacement of the valve can lead to inefficiencies or system failures. Therefore, this guide offers comprehensive insights into the replacement process of a solar direct valve.

UNDERSTANDING SOLAR DIRECT VALVES

1. COMPONENTS OF SOLAR DIRECT VALVES

Solar direct valves consist of various components, including bodies, seals, spring mechanisms, and actuators. The body is typically made from durable materials designed to withstand pressures and temperatures associated with solar heating applications. Seals prevent fluid leaks and are essential for maintaining system integrity, while springs control the opening and closing mechanisms of the valve.

The efficiency of the solar collector relies heavily upon these components functioning optimally. When one component fails, it can impact the performance of the entire system. Regular inspections and maintenance can help identify potential failures before they escalate into significant issues, emphasizing the need for quality components in solar direct valve design.

2. SIGNS OF MALFUNCTION

Recognizing the signs of a malfunctioning direct valve becomes paramount for timely replacements. Leaking is one of the first indications that the valve may require attention. Not only does this risk damage to other components, but it also compromises the efficiency of heat transfer. Decreased heating performance can also signal issues within the valve. If the solar system is not producing hot water effectively, the flow control mechanism within the valve may be impeded or completely blocked.

Another sign involves unusual noises coming from the valve during operation. This can include rattling sounds or persistent hissing, which may suggest internal mechanical failure or pressure imbalances. Regular checks can help catch these problems early, ensuring that system downtime is minimized and health standards maintained.

PREPARING FOR REPLACEMENT

3. TOOLS AND MATERIALS NEEDED

Before embarking on the replacement process, proper preparation is essential. Tools such as wrenches, screwdrivers, and pliers will be necessary for loosened fittings and attachments. Depending on the exact nature of the installation, specialized tools may also be required to handle specific types of direct valves.

Gathering new replacement parts is another critical step. The correct valve size and type must be confirmed before proceeding. Incorrect replacements can lead to further issues down the line. It is advisable to consult with the manufacturer or a knowledgeable supplier to ensure that all parts are compatible with the existing solar system.

4. SAFETY PRECAUTIONS

Safety is of utmost importance during the replacement process. Before any work begins, ensure that the system has been de-pressurized and completely drained. This step is crucial, as residual pressure can result in unexpected sprays of hot fluid or steam, posing significant hazards.

Wearing appropriate personal protective equipment (PPE) such as gloves and goggles is essential to protect against potential leaks or splashes from fluids. Ensuring adequate ventilation in the working area is also advisable, as any fluids involved can emit gases or odors. Thorough adherence to safety protocols can prevent workplace accidents while ensuring a successful valve replacement.

PERFORMING THE REPLACEMENT

5. REMOVING THE OLD VALVE

To commence the replacement, locate and accurately identify the existing direct valve. Disconnect any electrical components or controls linked to the valve before loosening and detaching it. Use the appropriate wrenches to systematically remove bolts or screws securing the valve in place.

Be prepared for residual fluids to escape during disconnection. It is wise to have a container or towels ready to catch any spillage. Once unfastened, carefully remove the old valve from its housing, taking extra caution not to damage any adjoining components. This meticulous approach will ensure a smoother replacement process and safeguard the integrity of surrounding infrastructure.

6. INSTALLING THE NEW VALVE

With the old valve removed, the installation of the new solar direct valve can proceed. Ensure that the mounting surface is clean and free from debris, which could impede the new valve’s sealing. Align the new valve with the mounting points and secure it into position. Apply the appropriate torque specifications to bolts or screws to ensure a tight fit.

Before proceeding, verify that all seals are correctly positioned to prevent leaks. Reconnect any electrical components that were previously detached, ensuring all wiring is secure and functioning properly. A thorough inspection of the setup prior to re-pressurizing the system can save significant time and resources.

TESTING AND MAINTAINING THE NEW VALVE

7. PRESSURIZING THE SYSTEM

After installation, it’s crucial to methodically re-pressurize the system. Gradually fill the system with the appropriate heat transfer fluid, allowing it to circulate within the defined pathways. As pressure returns, monitor closely for any signs of leaks or unusual behavior.

Maintaining vigilance during this process can help catch minor issues before they develop into formidable failures. Perform regular checks on the newly installed valve to confirm its proper functioning, particularly in the days following the installation. This proactive approach can help identify potential complications early, thereby extending the service life of both the valve and the overall system.

8. FREQUENT MAINTENANCE CHECKS

Routine maintenance checks of solar direct valves will extend their operational lifespan. Schedule periodic inspections, ideally seasonally or biannually, to keep abreast of any wear and tear. During these assessments, clear away any accumulated debris and inspect seals for signs of corrosion or damage. Regular flushing of the system can also remove particulates that might obstruct flow or cause harm to valve components.

Adopting a comprehensive maintenance schedule will benefit the entire solar heating system, enhancing efficiency and performance. Such diligence can prevent unexpected system downtimes, facilitating uninterrupted service and energy savings.

FREQUENTLY ASKED QUESTIONS

WHAT IS A SOLAR DIRECT VALVE?

A solar direct valve plays a crucial role in solar thermal heating systems by regulating the flow of heat transfer fluid between solar collectors and storage tanks. The valve opens and closes depending on temperature changes and fluid pressure, thereby ensuring optimal efficiency in heat transfer. When functioning correctly, these valves contribute to energy savings and effective heating. In cases where issues arise, such as leaks or blockages, performance may decline, necessitating timely maintenance or replacement. Choosing high-quality valves and conducting routine checks are essential for maintaining system integrity and functionality.

HOW OFTEN SHOULD SOLAR VALVES BE INSPECTED?

Inspecting solar valves is vital in preserving the efficiency and longevity of solar thermal systems. Ideally, these inspections should occur at least twice yearly, coinciding with seasonal changes. During inspections, look for signs of leaks, corrosion, or mechanical failures that could impede the valve’s operation. Regularly flushing the system to remove debris is also beneficial during these assessments. Early identification of issues allows for timely interventions, minimizing unexpected downtimes and maximizing energy savings. Hence, an established inspection routine is crucial in ensuring that the solar heating system operates efficiently throughout its intended lifespan.

CAN I REPLACE A SOLAR DIRECT VALVE MYSELF?

Replacing a solar direct valve can be performed by knowledgeable individuals who are familiar with mechanical systems and solar heating technology. However, it is essential to understand the intricacies involved before embarking on the process. If you have a good grasp of tools and safety procedures, the task can be manageable. However, if you are unfamiliar with the components or replacement procedures, seeking professional assistance may be more prudent. A professional can ensure that the job is done correctly, thereby maintaining the efficiency and longevity of the solar system. Ultimately, the decision to replace the valve by oneself should be made after careful consideration of personal skill levels and comfort with mechanical tasks.

A successful replacement of a solar direct valve requires careful planning, safety adherence, and systematic execution. Identifying the existing valve and understanding its components are critical first steps. Proper tools and safety precautions must be ensured before removal, followed by the installation of the new valve with meticulous attention to detail. The maintenance of the entire solar system depends significantly on the efficient functioning of its components, making it essential to perform routine checks and address any irregularities promptly. Emphasizing preventative maintenance will not only enhance performance but also promote sustainability within solar heating systems. The ultimate goal is to achieve a reliable, energy-efficient system that meets the needs of home or business owners while contributing positively to environmental goals. Investing time and resources into understanding and replacing the solar direct valve can yield significant returns in terms of efficiency, savings, and overall system longevity. Proper assessment and adherence to established protocols will guide homeowners and technicians alike in successfully managing these components long into the future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-replace-solar-direct-valve/