Replacing solar aluminum plastic tubes with PPR tubes can significantly enhance the efficiency and longevity of your solar water heating system. 1. Identify the need for replacement, 2. Select appropriate PPR tubing, 3. Gather necessary tools, 4. Execute the replacement procedure carefully. Among these points, the selection of appropriate PPR tubing is crucial, as the right diameter and specification ensure ideal flow rates and pressure durability, directly impacting overall performance.

1. INTRODUCTION TO SOLAR WATER SYSTEMS

Solar water heating systems are engineered to convert sunlight into thermal energy for domestic and commercial usage. These systems usually include various components, among which tubes are essential for conveying water to and from the solar collectors. Traditionally, you might find aluminum plastic tubes used in these applications; however, many homeowners and businesses are now exploring PPR (Polypropylene Random Copolymer) tubes as a superior alternative.

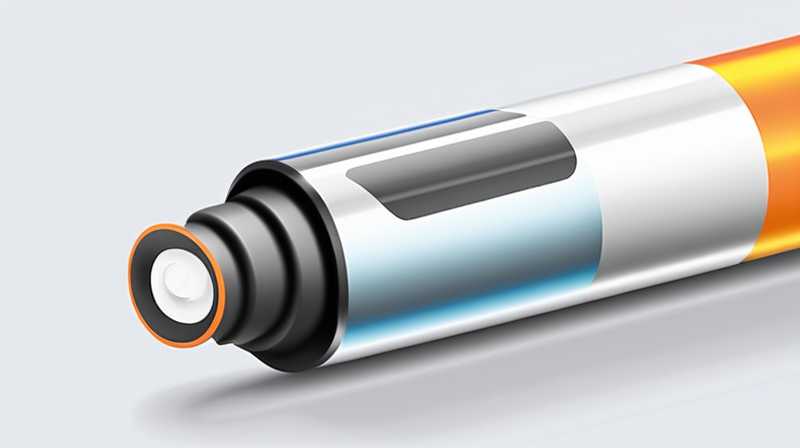

PPR tubing is known for its durability and resistance to temperature fluctuations, making it a practical choice for solar heating systems. Unlike the aluminum plastic tubes, which can suffer from degradation when exposed to high temperatures, PPR offers enhanced longevity and performance. The transition from aluminum plastic tubes to PPR can bring about improvements in energy efficiency and reduce the likelihood of leaks or failures in the system.

2. UNDERSTANDING PPR TUBING

PPR or Polypropylene Random Copolymer is frequently used in plumbing and heating applications due to its superior qualities. Specifically, it is lightweight, has excellent resistance to thermal shock, and poses a low risk of corrosion, significantly compared to metal or composite pipes. These attributes make it an optimal choice for hot water systems, including solar heaters.

When considering the adoption of PPR in place of aluminum plastic tubes, it’s essential to comprehend the various types and grades available in the market. Each variant has been engineered for specific applications. For instance, the PN rating (Pressure Nominal) of a pipe indicates its ability to withstand pressure over time, and this is crucial when selecting the right PPR tube size and type for your solar water heating system.

3. SUPPLIES AND TOOLS REQUIRED FOR THE REPLACEMENT

Before embarking on the replacement task, ensure you procure all necessary supplies and tools. Preparation stands as a vital step in ensuring a seamless transition. Among other requirements, obtaining PPR tubing of the accurate length and diameter specific to your existing framework is imperative.

Moreover, associated fittings, such as elbows and connectors, may be necessary to complete the installation effectively. The following tools will also be beneficial: a cutting tool for the PPR tubing, a heat fusion tool, and a pipe wrench. These tools not only streamline the installation process but also guarantee high connection integrity, which is essential for maintaining system pressure and efficiency over time.

4. REMOVING THE OLD ALUMINUM PLASTIC TUBES

Removing existing aluminum plastic tubes is pivotal in ensuring the seamless integration of PPR tubing. Begin the process by ensuring that the system is powered down and drained thoroughly. This precaution guarantees safety while also preventing any water damage to surrounding areas during this operation.

Utilizing a pipe wrench, carefully unscrew the fittings connecting the aluminum plastic tubes to the solar water heating system. Take care to avoid damaging adjacent components, as this could lead to additional repairs. Once detached, cut the tubes to facilitate their removal. After extracting them, inspect the condition of any remaining fittings or connectors and replace them if necessary to prevent future leaks.

5. INSTALLING PPR TUBES

Prior to installation, ensure that you’ve selected the right specifications and that the new PPR tube fits seamlessly with the current system. Begin by cutting the PPR tubing to the required lengths, utilizing a cutting tool that ensures clean, smooth edges. Such precision minimizes any potential blockage from jagged edges.

Once cut, employ a heat fusion tool to join the PPR fittings with the tubes, ensuring a strong, leak-free connection. This technique involves heating the ends of the tubes and fittings until they soften and then joining them together. Adequate cooling time is necessary for the joined sections to solidify, thereby creating a durable bond. After everything has set, visually inspect the connections for integrity, ensuring no gaps or irregularities that could lead to pressure loss.

6. TESTING FOR LEAKS

Testing for leaks is a fundamental step following the installation phase. Ensuring that all connections are secure is crucial to operational efficiency and longevity. Pressurize the system gradually and observe each joint, particularly those made using heat fusion, for any signs of leaking.

In cases where leaks are identified, immediate corrective action should be taken to rectify the matter. This might involve reheating and rejoining sections or, in some cases, replacing components altogether. Ensuring that the system is entirely leak-free is paramount before reinstating power and returning the system to active status.

7. MAINTENANCE AND UPKEEP OF PPR TUBING

Once the installation is completed, ongoing maintenance is vital for ensuring the performance and longevity of the PPR tubes. Regular inspection of the system for mechanical integrity and temperature fluctuations will help in identifying potential issues before they escalate.

Periodic cleaning of the PPR tubes can also enhance performance. While PPR is inherently resistant to buildup, periodic checks for scale or sediment may be beneficial, especially in areas with hard water. Maintain good practices in monitoring system performance to ensure sustained efficiency in water heating.

8. COST ANALYSIS OF REPLACING TUBES

Assessing financial implications is key in any home improvement decision, including replacing aluminum plastic tubes with PPR. Installation costs can vary based on the length of tubing required and additional fittings necessary. However, when evaluating long-term savings from improved energy efficiency and decreased maintenance demands, the upfront investment in PPR can prove advantageous.

Additionally, consider the lifespan of PPR versus aluminum plastic. PPR tubes can last significantly longer, potentially yielding savings over time through reduced replacement frequency and minimized leak-related repairs.

9. EVALUATING SYSTEM PERFORMANCE POST-REPLACEMENT

After completing the transition and having taken proactive measures in maintenance, it would be prudent to evaluate the performance of your solar heating system. As PPR offers enhanced thermal efficiency, closely monitoring improvement in water heating times and consistency of supply is advisable.

Be vigilant in monitoring for any unusual fluctuations in system performance, as early detection will facilitate timely interventions if issues arise. Analyzing system efficiency via billing and user feedback can also provide valuable insights into the success of the replacement process.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE BENEFITS OF USING PPR TUBES OVER ALUMINUM PLASTIC TUBES?

PPR tubes offer numerous benefits over aluminum plastic tubes, including enhanced durability, corrosion resistance, and better thermal insulation. The polymer composition of PPR enables it to withstand higher temperatures and pressures without degrading, making it particularly suitable for solar water heating applications. Unlike aluminum plastic, which may become brittle under prolonged exposure to UV rays or high temperatures, PPR maintains its structural integrity and performance over time. Additionally, the installation process for PPR is streamlined, often requiring fewer fittings due to its flexibility, which can foster a more efficient design. The reduced risk of leaks and lower operational costs associated with maintenance make PPR an increasingly popular choice among homeowners and contractors alike.

HOW LONG CAN PPR TUBES LAST IN A SOLAR WATER SYSTEM?

The lifespan of PPR tubes in a solar water system is significantly longer compared to their aluminum plastic counterparts. Under optimal conditions, PPR tubing can last anywhere from 25 to 50 years, depending on various factors such as installation quality, water quality, and system pressure. Unlike traditional materials, PPR is not prone to corrosion or deterioration, which enhances its longevity. It is resistant to scale buildup, contributing to smoother water flow and efficient heat transfer, which further aids in prolonging its lifespan. Conducting routine maintenance and inspections can also play a pivotal role in maximizing the longevity of your PPR tubing, ensuring it remains functional and efficient for several decades.

IS IT POSSIBLE TO DIY THE REPLACEMENT OF TUBES, OR SHOULD A PROFESSIONAL BE HIRED?

While replacing aluminum plastic tubes with PPR tubes may seem achievable as a DIY project, it is highly recommended to consult or hire a professional if you are not familiar with plumbing systems. A professional installer will possess the requisite expertise, ensuring proper installation according to safety standards. They are equipped to handle potential challenges such as the precise measurements, heat fusion requirements, and additional fittings that may be necessary, ensuring a flawless setup. Although DIY could save money upfront, faulty installations can lead to significant long-term costs due to water damage or frequent repairs. It’s prudent to assess your comfort level and experience with plumbing tasks before deciding whether to undertake this project independently or enlist professional help.

Transitioning from aluminum plastic tubes to PPR tubes in solar water heating systems is not merely a matter of preference but rather a step towards enhancing efficiency and durability. The entire procedure, from removal to installation and maintenance, must be approached with care and precision to optimize the benefits offered by PPR. Each component, from selecting the right tubing to ensuring flawless connections, plays a crucial role in the system’s overall effectiveness. The merits of PPR—its long lifespan, resistance to temperature fluctuations, and lower maintenance needs—solidify its position as a superior alternative in modern plumbing solutions. By investing in high-quality materials, performing thorough installations, and adhering to a consistent maintenance regime, homeowners and businesses can experience improved performance, reduced energy costs, and extended operational longevity. Ultimately, the shift to PPR can represent a significant upgrade, facilitating a more sustainable and efficient approach to utilizing solar energy for heating needs, aligning with contemporary environmental goals and enhancing overall user experience.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-replace-solar-aluminum-plastic-tube-with-ppr-tube/