To replace a solar two-way angle valve, one must carefully follow a series of steps to ensure efficiency and safety. 1. Safety Precautions – Before commencing any work, it’s crucial to ensure that the solar system is shut down and all relevant components are depressurized. This prevents accidents and injuries from occurring during the replacement process. 2. Identifying the Valve Location – Proper identification of the two-way angle valve within the solar system is essential, as it dictates the next steps in the replacement process. 3. Removing the Old Valve – The old valve must be disconnected with care, ensuring that no damage is inflicted on the surrounding pipes and components. 4. Installing the New Valve – Once the old component is removed, the new solar two-way angle valve can be installed, ensuring all seals are tight and secure. Proper tightening ensures there are no leaks, which is critical for the efficient functioning of the solar heating system.

Replacing a solar two-way angle valve is an essential maintenance procedure that anyone looking to maintain or upgrade their solar energy system should not overlook.

1. SAFETY PRECAUTIONS

One of the foremost aspects when undertaking any plumbing or maintenance task, particularly in a solar energy system, involves ensuring a safe work environment. Interacting with plumbing components can often pose hazards, particularly when pressurized systems are involved. The initial step is to turn off the solar energy system. This step guarantees that no overheating or leakage occurs during the process.

Equally vital is the release of pressure within the system. This may involve opening specific valves or fixtures to expel any trapped fluid within the pipes, significantly reducing the risk of injury or unintended spray during the removal of the valves. Taking precautionary measures, such as wearing gloves and protective eyewear, is paramount in this phase.

Additionally, preparing the workspace facilitates a smoother operation. This includes clearing any clutter, ensuring all necessary tools are within reach, and having materials such as rags ready for potential spills. Organized preparation not only aids efficiency but also minimizes accidents.

2. IDENTIFYING THE VALVE LOCATION

After ensuring safety, the subsequent task is pinpointing the exact location of the two-way angle valve within the solar system. Typically, this component is situated close to solar thermal collectors, allowing the system to regulate fluid flow effectively. Understanding the solar system layout is fundamental.

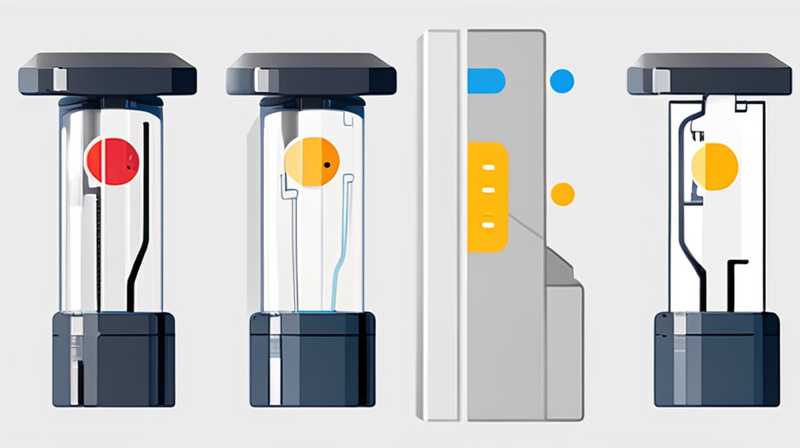

Before attempting to locate the valve, it would be beneficial to reference schematics or diagrams specific to the solar system in question. Familiarity with the system’s design aids in learning how the various components interact, particularly for future maintenance interventions. Often, the angle valve is placed strategically to facilitate easy access during servicing.

Physical inspection helps in determining whether further disassembly is necessary for easier access. In some cases, insulation may need to be removed to expose the valve adequately. Taking the time to understand the system layout prevents errors and streamlines the replacement process.

3. REMOVING THE OLD VALVE

With the exact position of the valve established, the next step is the careful disconnection of the existing two-way angle valve. This process should be executed with precision to avoid damage to nearby pipes or fittings. Using appropriate tools is essential.

Typically, a wrench is required for loosening the fittings, but one must ensure that the wrench is of the correct size to prevent stripping or damaging the nuts. It is advisable to apply penetrating oil if the fittings appear corroded or rusted. This oil helps in breaking down the corrosion, making disassembly significantly easier.

While disconnecting the valve, it is essential to collect any residual fluid that may escape from the pipes. Utilizing a small basin or bucket ensures that the workspace remains clean and prevents slipping hazards. After the valve is completely removed, it is crucial to inspect the condition of the surrounding pipes to detect any signs of wear or damage that may necessitate additional repairs.

4. INSTALLING THE NEW VALVE

Introducing the new solar two-way angle valve is a critical phase where careful attention to detail is essential. The first step involves ensuring that the replacement valve is compatible with the existing system requirements. This entails verifying measurements, flow ratings, and connection types. Compatibility ensures optimal functionality and longevity of the installation.

The installation commences by securely attaching the new valve to the existing plumbing. One should thread the valve into place hand-tight initially to prevent cross-threading, which can compromise the seal and lead to leaks. After hand-tightening, it is essential to use the wrench to further tighten the connection, but caution must be exercised not to over-tighten, as this can result in stripping the threads or damaging the valve.

Post-installation, the next crucial step involves carefully checking for any leaks by gradually re-pressurizing the system and observing the valve connections. If any leaks are detected, addressing them immediately is paramount, as leaks can lead to significant efficiency losses in the solar system. Once satisfied that no leaks are present, one can proceed to reassemble any insulation or coverings removed during the installation process, ensuring that the system is well-protected and insulated.

FAQs

WHAT SIGNS INDICATE A FAULTY TWO-WAY ANGLE VALVE?

Identifying issues with a two-way angle valve can be crucial for maintenance and efficient operation of a solar system. Common signs that indicate a malfunctioning valve include unusual noises, leaks, or inadequate heating performance. When a valve becomes faulty, it may not fully open or close, leading to reduced effectiveness in regulating the fluid flow. Additionally, one might notice a persistent drip or pooling fluid around the valve area, suggesting that the seals may have worn out.

Another important indicator is fluctuating temperatures within the system, which might stem from improper regulation of the fluid flow. Observing sudden drops or spikes in temperature could signify that the valve is stuck in an open or closed position. Thus, regular monitoring of the valve’s performance can prevent severe issues, ensuring that the solar heating system operates smoothly and efficiently.

HOW OFTEN SHOULD A SOLAR TWO-WAY ANGLE VALVE BE REPLACED?

The replacement frequency of a solar two-way angle valve largely depends on various factors including the specific model, usage intensity, and environmental conditions. While there’s no definitive rule, many solar energy professionals recommend inspecting the valve annually for any signs of wear and tear. Conducting an annual check helps in identifying minor issues before they evolve into significant problems.

In general terms, if a valve is showing signs of corrosion, rust, or leaks, it may require replacement sooner rather than later. Regular maintenance schedules should include the inspection of critical components like valves to ascertain their functionality. Based on expert insights, properly maintained valves can last anywhere between five to ten years, but this estimate varies based on the conditions mentioned earlier. Hence, staying proactive can lead to cost savings and efficient operation.

WHAT TOOLS ARE REQUIRED FOR REPLACING A SOLAR TWO-WAY ANGLE VALVE?

Equipping oneself with the proper tools is critical for replacing a solar two-way angle valve effectively. Essential tools include a wrench set that accommodates the size of the fittings, pliers, and screwdrivers for various components. Additionally, a basin or bucket is useful for capturing residual fluid during disassembly, preventing workplace hazards.

In ensuring a clean and effective workspace, a rag or cloth is also imperative to address any minor spills that may occur during the replacement process. For valves that are significantly old or corroded, a penetrating oil is suggested to loosen stubborn fittings. Lastly, safety equipment such as gloves and protective eyewear protects against unintentional harm and ensures safety throughout the operation. Having a comprehensive toolset prepared can make the replacement process significantly more efficient, reducing the chances of complications.

A thorough understanding of the process involved in replacing a solar two-way angle valve contributes significantly to the longevity and efficiency of the entire solar heating system. Establishing safety measures, accurately identifying components, executing the old valve’s removal, and installing a new valve meticulously represent crucial steps. Prioritizing these stages not only enhances the performance of the solar energy system but also supports an eco-friendly energy solution essential for sustainable living. Regular monitoring, including checks for wear and comprehensive understanding of potential issues, further fortifies the operational integrity of the system. Thus, proactive engagement in maintenance practices can lead to profound benefits, ensuring that solar heating systems serve their purpose effectively while remaining cost-efficient.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-replace-a-solar-two-way-angle-valve/