1. UNDERSTANDING A SOLAR BALL VALVE REPLACEMENT

Replacing a solar ball valve involves a systematic approach to ensure efficacy and functionality. 1. Identify the problem, 2. Gather necessary tools and parts, 3. Safely disconnect the faulty valve, 4. Install the new valve, 5. Test the system. The process requires understanding the unique characteristics of solar systems, where ball valves play a pivotal role in controlling fluid flow. Neglecting proper procedures can lead to further issues down the line.

2. ANALYZING THE ROLE OF SOLAR BALL VALVES

Solar ball valves are essential components in solar heating systems. They serve the purpose of regulating and controlling the flow of fluids, enabling optimal energy transfer and maintaining system efficiency. The operation of these valves is crucial as any malfunction can lead to decreased performance or even system failure. Solar ball valves prevent backflow, which is vital for preserving system integrity.

Moreover, these valves are designed to withstand varying pressure and temperature conditions, making them suitable for solar applications. Their construction—typically comprised of durable materials like brass or plastic—ensures longevity and reliability. Understanding the importance of these components in solar applications informs users on the necessity of replacements and maintenance.

3. IDENTIFYING SIGNS OF A FAULTY VALVE

Recognizing when a solar ball valve needs replacement is critical for maintaining system efficiency. There are several indicators that suggest a valve may be malfunctioning. 1. Leaks at the valve connections, 2. Difficulty in opening or closing the valve, 3. Unusual noises during operation, 4. Fluctuations in temperature or pressure readings, 5. Visible corrosion or damage on the valve body.

Leaky connections often point to wear and tear. Water escaping from joints indicates that sealing is compromised, leading to potential system inefficiencies. Difficulty in operation may indicate internal wear or obstruction, often requiring immediate attention to prevent further damage.

Unusual noises stem from improper fluid dynamics caused by a faulty valve, suggesting that it either needs repair or complete replacement. Temperature and pressure fluctuations can signal improper flow regulation, illustrating the necessity for a replacement valve to restore balance. Visual inspections revealing corrosion or material degradation necessitate urgent action to ensure continued optimal performance.

4. GATHERING NECESSARY TOOLS AND PARTS

Before initiating the replacement process, it is vital to assemble the appropriate tools and components. Key items often include 1. A new solar ball valve compatible with the existing system, 2. Pipe wrenches for disconnection, 3. Teflon tape or sealant for a leak-proof seal, 4. Safety goggles and gloves to protect against hazardous materials. Organizing these tools in advance saves time and simplifies the replacement process.

Choosing the right replacement valve is paramount, as compatibility with existing pipes and fittings ensures optimal performance. Differentiating between various types of valves—such as electric versus manual—based on the system’s requirements is crucial. Additionally, assessing the materials used in the valve construction allows for better compatibility with the system’s working conditions.

Pipe wrenches facilitate the removal of existing valves, ensuring a tight grip to prevent damage during disassembly. Adequate protection through safety gear safeguards against inadvertent spills or accidents during the process. Forethought in preparation significantly enhances the efficiency of the valve replacement endeavor.

5. TO SAFELY DISCONNECT THE FAULTY VALVE

Initiating the replacement involves safely disconnecting the faulty valve, a paramount step to ensure safety and system integrity. Begin by 1. Shutting down the solar heating system, 2. Draining any excess fluid from the system, 3. Loosening the connections using the pipe wrenches, 4. Removing the valve from the pipe fittings. Each of these steps must be done with care to avoid potential risks.

Shutting down the system serves two critical functions: it protects the user from possible burns or electrical hazards and prevents fluid pressure from interfering with the removal process. Draining excess fluid is essential to avoid spills that could not only cause personal injuries but also compromise the surrounding areas.

As connections are loosened, maintaining stability within the system is vital. A careful approach ensures that adjacent pipes and connections remain intact. Once the old valve is adequately loosened and removed, cleanliness around the work site is also necessary to prevent debris from interfering with the new valve installation.

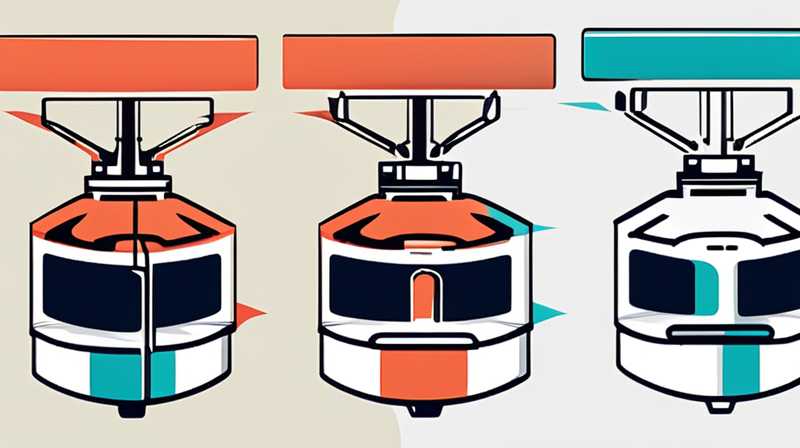

6. INSTALLING THE NEW VALVE

After removing the inefficient valve, the next stage involves installing the new solar ball valve. This includes 1. Preparing the pipe fittings for the new valve, 2. Applying Teflon tape or sealant to ensure a watertight connection, 3. Securely attaching the new valve, 4. Double-checking all connections before system reactivation.

Prior to installation, inspecting the condition of the pipe fittings is necessary. Clean surfaces promote better sealing and reduce the risk of future leaks. Applying Teflon tape or sealant in a clockwise direction along the threads of the pipe ensures a firm and leak-proof fit.

Once these preparations are complete, securely attach the new valve, making sure it aligns correctly with the existing plumbing system. Tightening connections to the manufacturer’s specifications reinforces the system’s integrity. Before reactivating the solar heating system, it is prudent to conduct a final visual inspection to confirm that all connections are secure and that no debris has entered the plumbing.

7. TESTING THE SYSTEM POST-REPLACEMENT

With the new valve installed, conducting thorough tests to ensure optimal functionality is essential. 1. Reactivate the solar heating system, 2. Monitor for leaks, 3. Check fluid flow and valve operation, 4. Record any unusual behaviors for further investigation. This testing phase indicates whether the replacement has been successfully executed and highlights any adjustments necessary.

Reactivation allows for the immediate assessment of the valve’s performance within the system. Observing for leaks during this initial phase reveals whether the installation was effective; any visible leaking requires immediate re-evaluation of connections.

Fluid flow should be monitored to confirm that the valve behaves as expected, appropriately regulating the system’s circulation. Assessing the connections and observing their alignment with system specifications contribute to confirming successful installation. Documenting any irregularities that arise can help pinpoint areas needing adjustment and provide data for future maintenance considerations.

8. MAINTAINING VALVE INTEGRITY POST-REPLACEMENT

To prolong the lifespan of the newly installed valve, consistent maintenance practices will yield the best results. 1. Schedule routine inspections, 2. Clean the valve and its surroundings regularly, 3. Monitor pressure and temperature levels, 4. Address any issues promptly before they escalate. This standard approach allows for identifying potential problems early, maintaining optimal system performance.

Routine inspections involve checking the valve and all connections for signs of wear or leaks. Implementing a scheduling system establishes regular intervals which enhance oversight and decrease the chances of unnoticed complications. Ensuring cleanliness extends beyond just aesthetics; removing debris minimizes the risk of clogs and malfunctions.

Monitoring pressure and temperature readings provides insight into the system’s operational status. Any abnormalities should trigger quick assessments to mitigate risks of failure or costly repairs. Remaining vigilant helps in maintaining the system’s integrity and safeguards against prolonged downtimes.

9. STRATEGIES FOR FUTURE REPLACEMENTS

In optimizing future replacements, it is worthwhile to 1. Research high-quality valve options suited for solar applications, 2. Document prior valve performances for comparison, 3. Consider professional assistance when necessary, 4. Stay informed on emerging technologies in solar systems. Taking these proactive steps prepares users for future challenges and fosters systems that perform efficiently.

Researching high-quality options promotes informed decision-making, ensuring an investment in durable, long-lasting valves. Maintaining records of past performances helps identify trends that affect the system over time. Understanding which valves functioned successfully can influence future replacements.

Seeking professional assistance provides guidance in complex scenarios. Sometimes, the intricacies of a system may necessitate expertise beyond general installation knowledge. Remaining informed about advancements in technology enhances users’ ability to make choices that align with evolving industry standards.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE SIGNS THAT MY SOLAR BALL VALVE NEEDS REPLACEMENT?

Identifying the necessity for a solar ball valve replacement can often be nuanced. Common indicators include visible leaks around the valve, which easily suggest compromised seals. Additionally, difficulty in operating the valve, including issues with opening or closing, often reflects internal wear, signaling the need for a replacement. Unusual noises during operation, such as grinding or rattling, can indicate improper fluid dynamics, warranting further investigation. Likewise, fluctuations in temperature and pressure readings provide insight into potential malfunction. Corrosion or visible deterioration of the valve further reinforces the necessity for prompt attention to prevent systemic failures.

HOW DO I CHOOSE A COMPATIBLE REPLACEMENT VALVE FOR MY SYSTEM?

When selecting a replacement for a solar ball valve, consider the existing system’s specifications as a priority. Start by examining the valve’s size and thread type, ensuring a snug fit with existing pipes. Researching the material composition is also helpful; materials like brass or plastic may suit different system types and environments. Understanding the valve’s pressure and temperature ratings ensures suitability for solar applications. It’s also prudent to consult with manufacturers or specialists to clarify compatibility concerns. Overall, thorough product comparisons mitigate risks of poor valve performance, ensuring a successful replacement process.

WHAT CAN I DO TO EXTEND THE LIFE OF MY SOLAR BALL VALVE?

To prolong the lifespan of a solar ball valve, adopting a routine maintenance and inspection protocol is vital. Begin by establishing a scheduled routine for inspections, focusing on detection of leaks and wear over time. Regular cleaning of the valve and adjacent areas minimizes debris interference, enhancing overall performance. Proactively monitoring pressure and temperature levels ensures any deviations are caught early, preventing potential failures. Additionally, promptly addressing any emerging issues enhances the valve’s longevity and safeguards against significant repairs or system downtimes. By integrating these practices, a user can significantly extend the functional life of their solar ball valve.

10. REINFORCING THE NEED FOR KNOWLEDGE IN VALVE REPLACEMENT

Understanding the intricacies of replacing a solar ball valve is paramount to ensuring optimal function within solar heating systems. By taking the time to learn about this crucial component, individuals can avoid costly mistakes. Equipped with the right knowledge and tools, the process of valve replacement becomes a straightforward endeavor. Recognizing the importance of preparation, recognizing signs of deterioration, and adhering to systematic replacement procedures empowers users to maintain their solar systems efficiently.

By fostering a commitment to regular maintenance and promptly addressing issues, solar system operators can achieve improved performance and longevity from their systems. Ultimately, continuous learning and application of best practices form the foundation of effective solar energy management, allowing users to harness environmental resources sustainably.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-replace-a-solar-ball-valve/