1. Understanding the Process of Replacing a Broken Solar Control Valve

2. The Importance of Safety Precautions

3. Tools and Materials Required

4. Step-by-Step Guide to Removal and Replacement

5. Testing the New Valve

6. Regular Maintenance for Longevity

In addressing the requirements for replacing a broken solar control valve, several key points emerge. Firstly, proper identification of the valve type is crucial, as different systems may utilize various models. Secondly, ensuring that the system is turned off and depressurized is vital for safety, as working with pressurized systems can lead to injury. Thirdly, using the correct tools is necessary for effective removal and installation, which helps prevent damage to the new valve. Fourthly, after installation, thorough testing to check for leaks and proper functionality is essential.

Detrimental effects of neglecting these steps can include costly repairs, reduced system efficiency, and safety hazards. Continuing on, let us delve into a comprehensive analysis of each aspect concerning the replacement process.

1. UNDERSTANDING THE PROCESS OF REPLACING A BROKEN SOLAR CONTROL VALVE

To grasp the nuances of replacing a dysfunctional solar control valve, it is essential to first understand what this component does. The solar control valve manages the flow of fluid in solar heating systems, ensuring that the heat transfer fluid circulates efficiently to gather heat from the solar collectors and deliver it to the storage tank. When this valve becomes inoperative, the entire system’s functionality may be compromised, leading to reduced heating efficiency, increased energy consumption, or even system failure.

Identification of the Problem

Often, the initial indicators of a malfunctioning solar control valve include inconsistent heating or unusual noises from the system. It is imperative to accurately diagnose the issue. Common signs of a broken valve include leaks, inability to open or close properly, and erratic temperature fluctuations. When these symptoms are observed, inspection of the valve becomes the first critical step. Once identified, the valve type and specifications should be reviewed to ensure the correct replacement part is sourced.

2. THE IMPORTANCE OF SAFETY PRECAUTIONS

Prior to embarking on any repair tasks, especially those involving plumbing and pressurized systems, adherence to safety protocols cannot be overstated. The incorrect handling of pressurized systems poses serious risks, including injury and damage to property.

Safety Gear and Procedures

Wearing appropriate safety gear is fundamental. Protective eyewear, gloves, and long sleeves help minimize the risk of injuries from splashing fluids and sharp tools. Furthermore, assessing the work area for hazards, ensuring good ventilation, and keeping tools organized can contribute significantly to a safer working environment. Cutting power to the system and relieving pressure from the lines is a non-negotiable step that should be carried out before commencing any work.

3. TOOLS AND MATERIALS REQUIRED

A thorough understanding of required tools and materials is vital for a seamless replacement process. The right equipment not only ensures efficiency but also mitigates the risk of damaging components during the installation.

Essential Tools

Commonly required tools include wrenches, screwdrivers, and pliers. Wrenches are necessary for loosening bolts and fittings, while screwdrivers assist with any small components needing adjustments. Additionally, a multimeter may be beneficial for testing electrical components related to the valve.

Replacement Parts

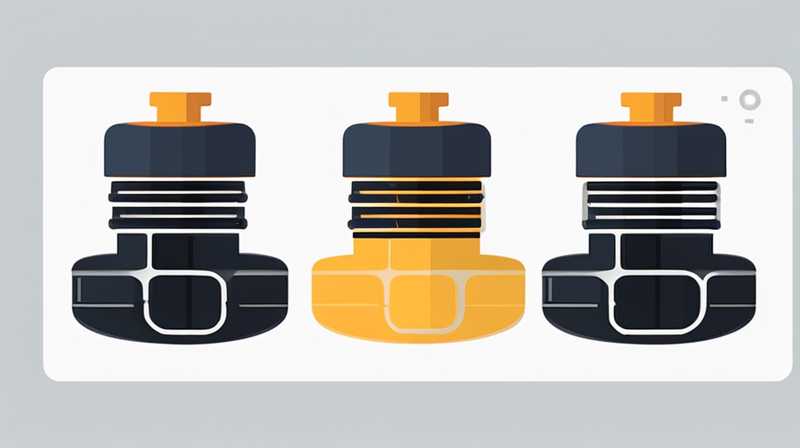

Selecting the proper replacement part is equally crucial. It is advisable to acquire a valve that matches the original specifications. Always refer to the manufacturer’s guidelines to ensure compatibility with the existing system. Quality should be prioritized, as investing in higher-quality components may provide better performance and longevity.

4. STEP-BY-STEP GUIDE TO REMOVAL AND REPLACEMENT

Executing the replacement of a broken solar control valve requires adherence to a meticulous procedure. Following established guidelines helps foster an efficient and successful repair.

Initial Preparations

Start by turning off the power to the solar heating system. After powering down, locate the valve and determine the exact replacement procedure based on your specific valve type and model. It can be beneficial to take pictures prior to disassembly, serving as a reference when reassembling parts. Next, drain any excess fluid from the system to prevent spills and maintain a clean workspace.

Removing the Broken Valve

Carefully disconnect any electrical connections and loosen and remove the bolts securing the old valve. Keep the removed components organized for easy reassembly. Once the old valve is removed, inspect the surrounding area for any signs of wear or damage that may need attention before installing the new valve.

Installing the New Valve

Position the new valve in place, ensuring it is aligned with the existing connections. Tighten bolts according to the manufacturer’s specifications, ensuring not to over-tighten as this may cause damage. Reconnect any electrical wires or attachments, making sure connections are secure and dust-free. The installation may also include applying thread sealant to connections to help prevent leaks.

5. TESTING THE NEW VALVE

Once the replacement is complete, a series of tests should be conducted to ascertain both functionality and safety. This phase is crucial in ensuring that the newly installed valve operates effectively.

Leak Test

Start by repressurizing the system slowly and monitoring for leaks at all connection points. Any leaks detected should be addressed immediately to avoid complications. Running the system at a low output initially can assist in this leak testing phase.

Check for Proper Operation

After confirming there are no leaks, examine the valve’s operation. Adjust settings and ensure that the valve opens and closes as intended, allowing for proper fluid flow. Monitoring the performance over the following few days can help ascertain that everything is functioning as it should be.

6. REGULAR MAINTENANCE FOR LONGEVITY

Completing the replacement process does not mark the end of your responsibilities concerning the solar control valve. Establishing a routine maintenance schedule greatly increases the lifespan of solar heating components.

Scheduled Inspections

Plan visual inspections periodically to check for wear and tear or signs of leaks. Keeping technological components clean and clear of debris can significantly enhance performance. Regularly monitor system performance metrics to identify any anomalies early on.

Educating Yourself on System Operations

Educating oneself on how the solar heating system operates can pave the way for early detection of potential problems. Understanding performance changes and recognizing the signs of a malfunctioning valve can lead to timely interventions, preventing larger issues from developing.

FREQUENTLY ASKED QUESTIONS

WHAT IS A SOLAR CONTROL VALVE, AND WHY IS IT IMPORTANT?

A solar control valve is a specialized component within solar heating systems, responsible for regulating the flow of heat transfer fluid. By ensuring optimal fluid circulation, this valve significantly enhances the overall efficiency of the system. When the valve operates properly, it maintains stable temperatures, ensures timely heat transfer from solar collectors to storage tanks, and avoids overheating situations, which can damage system components. Therefore, a functional solar control valve is pivotal in maintaining system efficiency and prolonging its lifespan.

HOW CAN I DETERMINE IF MY SOLAR CONTROL VALVE IS BROKEN?

Identifying a malfunctioning solar control valve can be crucial to maintaining the efficiency of your solar system. Key indicators include erratic or inconsistent heating, unusual noises, or leaks around the valve area. Additionally, you might notice a lack of temperature regulation or a significant rise in energy bills, suggesting that the system is not operating optimally. Should you observe these symptoms, inspecting the valve as soon as possible is essential to prevent further damage to the system.

CAN I REPAIR A BROKEN SOLAR CONTROL VALVE, OR SHOULD I REPLACE IT?

Whether to repair or replace a broken solar control valve often depends on the extent of the damage and the overall condition of the valve. Minor issues, such as debris caught causing obstructions, may often be fixed with cleaning. However, if the valve exhibits signs of physical damage, leaks, or consistent operational failure, opting for a replacement is typically the wiser course of action. This decision ensures that the solar heating system operates efficiently, preventing the likelihood of recurring problems that can arise from attempting to repair significantly damaged components.

GETTING IT RIGHT WITH VALVE REPLACEMENT

Replacing a broken solar control valve demands careful attention to detail and a commitment to safety. Throughout the entire procedure, understanding the implications of each step is vital to both safety and operational efficiency. Timing is also significant, as neglecting repairs promptly can lead to decreased performance and costly future fixes. As such, wishing to engage in this DIY task requires a thorough understanding of tools, materials, and procedural guidelines.

By prioritizing preventative measures after installation—like regular inspections and maintenance—you not only improve the immediate performance of your solar heating system but also extend its lifespan significantly. Emphasizing functionality, safety, and education on system operations will serve to alleviate potential future issues, ensuring a consistent supply of warm water. This diligence not only fosters a more sustainable home environment but stands to enhance energy savings significantly. Taking these proactive steps ensures that any repairs to solar control valves lead toward a longer-lasting and more efficient system.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-replace-a-broken-solar-control-valve/