To repair a solar temperature control valve core, the following steps should be taken: 1. Identification of issues with the valve core, 2. Gathering necessary tools and materials, 3. Following disassembly and inspection procedures, 4. Replacing damaged components, 5. Reassembling and testing the valve core. A detailed examination of the valve core’s functionality is essential, as this component regulates system temperatures to optimize efficiency. Without proper service, the solar heating system may experience operational failures that lead to unnecessary energy costs and reduced performance. Each stage of the repair process demands careful attention to detail for successful restoration.

1. IDENTIFICATION OF ISSUES WITH THE VALVE CORE

Initiating the repair process involves recognizing the symptoms manifesting from the temperature control valve. A valve core that is malfunctioning can trigger numerous problems, including inefficient heating or cooling, erratic temperature fluctuations, or even complete system failure. Often, these issues stem from wear and tear, dirt accumulation, or internal component damage.

Observing the operational behavior of the solar system provides critical insights into the specific problems encountered. For instance, if the solar collectors are not reaching optimal temperatures, it may indicate that the valve core is stuck or has lost its ability to open or close as required. Additionally, unusual noises or leaks can also be indicative of a malfunctioning component. A meticulous assessment of these signs allows for a more accurate diagnosis and helps in determining whether repair or component replacement is necessary.

2. GATHERING NECESSARY TOOLS AND MATERIALS

Once the valve issues are analyzed, the next step requires acquiring the correct tools and components required for repair. Essential tools typically include a wrench set, screwdrivers (both flathead and Phillips), pliers, and an assortment of replacement parts tailored specifically for the valve’s configuration.

Research into the specifications of the valve core is crucial for gathering the right materials. This research involves identifying the model and brand of the temperature control valve, including the specific type of core used within. Often, manufacturers provide detailed manuals that suggest the correct parts and tools needed for repairs. Compiling a comprehensive toolkit in advance not only streamlines the repair process but also minimizes the complications that arise from unnecessary back-and-forth trips to the hardware store.

3. DISASSEMBLY AND INSPECTION PROCEDURES

Dismantling the temperature control valve should be executed with care to avoid damaging the component and surrounding apparatus. Initially, it is recommended to shut off any power supplied to the system to ensure personal safety and prevent unintended operation during repairs. Following that, carefully disconnect the valve from the plumbing fixtures and inspect all attachments for any signs of damage or wear.

With the valve detached, a thorough examination of its interior may reveal accumulation of dirt, scale, or other contaminants that impede functionality. Such contaminants often lead to improper sealing or functioning of the valve core, ultimately reducing the system’s efficiency. As each part is removed, documenting their order and condition will be beneficial during reassembly, making it easier to identify critical components that require replacement or further attention.

4. REPLACING DAMAGED COMPONENTS

After inspection, it becomes evident which specific parts require replacement. The valve core itself may need to be substituted if significant wear or damage is apparent. Replacement cores are typically available through manufacturer supply stores, online retailers, or plumbing specialty outlets. It is paramount to verify that the replacement part matches the original specifications to ensure compatibility and optimal operation.

In some instances, gaskets or seals may also require attention. Aging and deteriorated seals can lead to leaks, compromising the system’s efficiency. Replacing these components during the repair not only fixes immediate issues but also extends the life of the valve and the solar heating system as a whole. Once new parts are procured, the following key step involves careful installation, where attention to torque specifications and orientation is essential to maintain proper function.

5. REASSEMBLING AND TESTING THE VALVE CORE

Following the replacement of damaged components, preparations must be made to reassemble the valve. It is crucial to reverse the disassembly steps methodically while ensuring every part is restored to its intended position. Correctly aligning and tightening all fittings will mitigate possible leaks and enhance operational efficiency.

After reassembly, a comprehensive testing phase must be conducted to verify the valve’s functionality. Testing usually involves exposing the system to operational pressures and temperatures to ascertain that the solar temperature control valve responds appropriately. During this phase, monitoring for leaks is critical, as even minor issues can lead to significant problems over time. Testing provides an overall confirmation that the repair process has been successful and that the solar heating system is well-prepared for optimal performance moving forward.

WHAT IS A SOLAR TEMPERATURE CONTROL VALVE CORE?

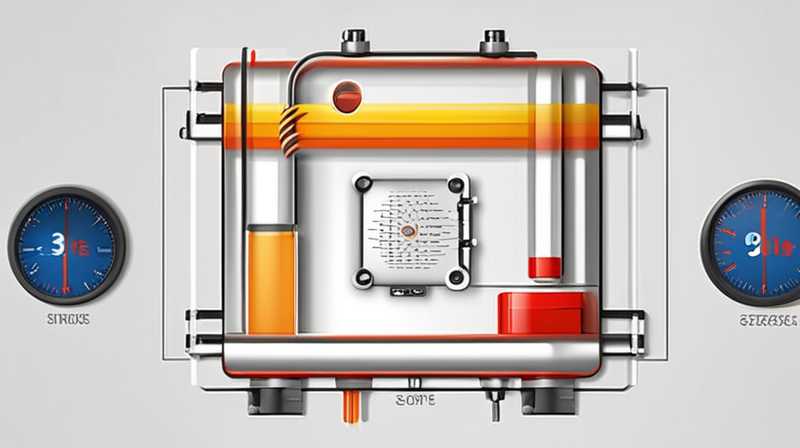

The solar temperature control valve core is a vital component within a solar heating system. Its primary function involves regulating the flow of heat transfer fluid, ensuring that heat is distributed efficiently within the system. When functioning effectively, it contributes substantially to energy savings and improves the overall performance of solar thermal installations.

HOW OFTEN SHOULD A VALVE CORE BE CHECKED?

Periodic inspections of a valve core are recommended to maintain the functionality of a solar heating system. Generally, at least once a year is suggested, particularly before the heating season begins. These checks help to identify early signs of wear or damage, facilitating timely repairs that can prevent more extensive issues down the line.

WHAT ARE THE COMMON SIGNS OF A MALFUNCTIONING VALVE CORE?

Indicators of a malfunctioning valve core include erratic heating patterns, noticeable leaks, unusual noises from the system, or failure to reach pre-established temperature thresholds. If any of these symptoms are observed, it is crucial to conduct an inspection to ascertain the health of the valve core, as neglecting these signs can lead to more severe system failures.

Through an intricate understanding of solar temperature control valve cores, effective repair efforts can be strategically implemented. Recognizing issues accurately allows for targeted action, while careful gathering of tools and diligent assessment during disassembly increases the likelihood of success. Each phase from component replacement to systematic testing deems crucial for securing the optimal operation of the solar heating system. By regularly maintaining and repairing these components, the longevity and efficiency of the solar heating installation can be ensured, preserving energy and providing sustainable heating solutions for years to come.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-repair-the-solar-temperature-control-valve-core/