Repairing a solar automatic mixing valve involves several steps to ensure proper functionality. 1. Assess the condition of the valve, which may include looking for leaks, corrosion, or mechanical failure. 2. Gather necessary tools and replacements, such as screwdrivers, wrenches, and sealing materials. 3. Follow manufacturer guidelines, ensuring each component is handled correctly. 4. Reassemble the valve carefully, making sure all seals are intact to prevent future leaks. One critical point to note is the need for periodic maintenance checks, as neglecting these can lead to significant issues over time, affecting overall system efficiency and resulting in costly repairs.

1. UNDERSTANDING THE SOLAR AUTOMATIC MIXING VALVE

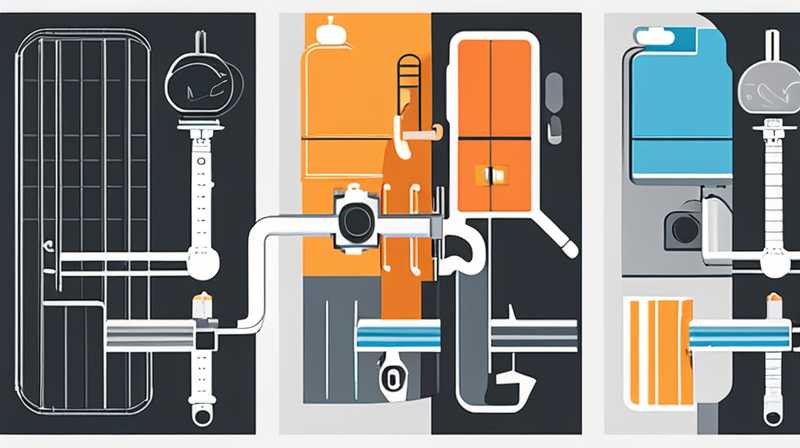

The solar automatic mixing valve plays a crucial role in solar heating systems, controlling and regulating the temperatures of fluids circulating through the system. This valve adjusts the mix of hot water produced by solar collectors with cooler return water, achieving an optimal temperature for domestic use or system efficiency. An understanding of this valve is essential, especially when it becomes necessary to troubleshoot or repair.

A thorough comprehension of the valve’s design and function will provide insight into its operation. The mixing valve typically consists of various components, including the valve body, control mechanism, and sensors that detect water temperature. These elements work in unison, allowing the valve to maintain a consistent output temperature, thereby preventing overheating or underheating. Understanding these functions leads to better decisions during the repair process, minimizing the possibility of further complications.

2. COMMON ISSUES WITH SOLAR AUTOMATIC MIXING VALVES

Numerous issues may arise with solar automatic mixing valves that can necessitate repair. Among the most prevalent challenges are leaks, temperature inconsistencies, and mechanical failures. Each of these problems can severely impact the effectiveness of a solar heating system.

Leaks can occur for various reasons, such as wear and tear over time or improper installation. When a leak develops, it leads to loss of valuable heated water, affecting efficiency and increasing energy costs. Finding the source of a leak requires careful inspection of all connections and seals. Often, replacing worn-out seals or tightening connection points resolves the leakage issue. It is imperative to objectively evaluate whether a repair or complete replacement of the valve is more economical, given the leak’s severity.

Temperature inconsistencies often manifest as the output water being either too hot or too cold, leading to discomfort in using hot water for daily activities. This problem usually arises due to malfunctioning sensors or control mechanisms. Checking and calibrating sensors to ensure they are functioning properly can greatly improve the valve’s accuracy in regulating temperature. In some cases, software or control unit updates may be necessary, depending on the manufacturer’s specifications.

3. GATHERING TOOLS AND REPLACEMENT PARTS

A successful repair of a solar automatic mixing valve requires appropriate tools and potential replacement parts. Essential tools may include a standard set of screwdrivers, wrenches, pliers, and a torque wrench. Having a compatible sealing medium, such as Teflon tape or gaskets, is vital to prevent future leaks following reassembly.

When sourcing replacement parts, ensure that the components meet the specifications designated by the valve’s manufacturer. Using substandard or incompatible replacement parts can lead to premature valve failure, negating any repair efforts. Researching compatible products by cross-referencing part numbers can save time and effort in obtaining the necessary materials.

Additionally, consider preventive components that can be installed during the repair. If the valve lacks adequate thermal insulation, installing insulation sleeves can help maintain the temperature of hot water flowing through the system, thus enhancing overall efficiency. Moreover, maintaining a stock of common replacement parts can aid in expediting future repairs, thereby reducing downtime of the solar heating system.

4. DIAGNOSING THE PROBLEM

Before embarking on repairs, conducting a thorough diagnosis is crucial to identify the root causes of the issues at hand. Visual inspections combined with functional tests can reveal hidden problems not immediately apparent during informal assessment. Additionally, leveraging diagnostic equipment can help pinpoint anomalies within the valve’s performance.

Common diagnostic procedures include checking water flow rates, temperature differentials, and pressure readings within the system. Establishing baseline performance metrics allows for effective comparisons, enabling technicians to assess the extent of any discrepancies accurately. It is essential to document these tests to track changes and improvements post-repair.

Furthermore, in some situations, it may be beneficial to engage software to aid in diagnosis, particularly for modern solar heating systems equipped with smart technology, making it easier to troubleshoot issues without excessive time expenditure.

5. EXECUTING THE REPAIR

Upon completion of the diagnostic phase and ensuring all necessary tools and parts are ready, the actual repair process can commence. Adhere carefully to the manufacturer’s instructions at this stage, as deviating from recommended practices can hinder the effectiveness of the repair.

Begin by disconnecting the valve from the system, ensuring no residual solar fluid remains to avoid spills. Meticulously remove all components, taking note of their arrangement for easier reassembly later. Inspect each segment for damage, corrosion, or wear, focusing on seals and mechanical parts that collide frequently during operation.

If significant damage is identified, consider replacing the entire valve assembly rather than attempting to salvage damaged components. Once all worn parts are replaced, reassemble the valve carefully, ensuring all seals are properly positioned and secure.

6. TESTING THE REPAIRED VALVE

After reassembly, the repaired valve should undergo thorough testing before re-initiating it into regular service. Begin by gradually restoring flow to the valve, monitoring for leaks at all joints and seals. This step is imperative to confirm the integrity of the repairs performed.

Additionally, check the temperature regulation by running hot and cold water through the valve and observing if it delivers the desired temperatures accurately. Ensure proper calibrations on sensors and signals are maintained to achieve optimal performance. Testing may also involve monitoring pressure levels to ensure they align with manufacturer specifications.

In cases where the valve did not perform satisfactorily during testing, revisit previous steps to confirm that all components are installed correctly and functioning as intended. Re-evaluating each element can identify overlooked issues that might have been initially dismissed.

7. MAINTENANCE AND FUTURE PREVENTION

Post-repair maintenance plays a significant role in maintaining the longevity and reliability of a solar automatic mixing valve. Establishing a routine inspection schedule will help catch potential problems before they escalate, ensuring the system remains efficient over time.

Regular maintenance efforts should include checking for leaks, assessing temperature accuracy, and monitoring component wear. Refer to the manufacturer’s guidelines to determine the frequency and depth of inspections needed for optimal performance.

Additional preventative measures can include investing in superior quality components during initial installations, as these often withstand wear and provide higher efficiency over their lifespan. Wherever possible, consider utilizing smart monitoring technology that can notify homeowners or technicians of irregularities before they become critical failures.

8. RECOGNIZING WHEN TO CALL A PROFESSIONAL

While many repairs can be performed independently, recognizing the right moment to enlist professional help is equally important. If the repairs needed exceed basic maintenance or involve specific tooling not readily available, it may be in the best interest to contact an expert in solar energy systems.

Professional assistance can provide comprehensive insights and advanced skills to tackle complex problems effectively. An expert can also offer tailored maintenance plans that ensure the longevity of a solar heating system, potentially providing valuable warranties on parts and labor.

Additionally, if there is uncertainty about the diagnosis or repair, seeking assistance can prevent unnecessary damage to the system. Receiving a professional opinion can also substantiate the investment homeowners make in solar technology, promising optimal performance and longevity in operations.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE SIGNS THAT MY SOLAR AUTOMATIC MIXING VALVE NEEDS REPAIR?

Indicators that a solar automatic mixing valve requires repair include persistent water leaks, temperature fluctuations in the water supply, or unusual noises emanating from the valve assembly. When water drips or seeps from the valve or connection points, it indicates that seals may need replacement or that the valve body is compromised. Temperature irregularities, where water is either excessively hot or insufficiently warmed, suggest a malfunctioning internal mechanism or sensor that can’t properly regulate temperature. Unusual sounds can signal mechanical failures within the valve. Should any of these symptoms persist over time, it would be prudent to inspect or consult a technician for repairs, enhancing the performance of your solar heating system and preventing further damage.

HOW LONG DOES IT TAKE TO REPAIR A SOLAR AUTOMATIC MIXING VALVE?

The duration of repairing a solar automatic mixing valve depends on the complexity of the issue, the availability of parts, and the individual’s proficiency in handling such repairs. Generally, a straightforward repair involving component replacement or resealing may take approximately 1 to 3 hours, depending on circumstance. However, more extensive repairs that involve diagnostic checking, multiple faulty components, or detailed reassembling could take longer, ranging from half a day to a full day. Additionally, if professionals are engaged, the time frame might extend further as they assess and resolve underlying problems thoroughly, aiming to guarantee optimal functionality of the valve post-repair.

IS IT NECESSARY TO HIRE A PROFESSIONAL FOR REPAIRS AND MAINTENANCE?

While homeowners can undertake minor repairs to a solar automatic mixing valve, hiring a professional becomes essential when facing intricate issues or during the initial review and assessments. Professionals have specialized training and access to advanced tooling, enabling them to address complex problems that may not be evident to the untrained eye. Moreover, professionals often provide follow-up maintenance and warranties on repairs performed, ensuring peace of mind for homeowners regarding the reliability of their solar systems. If extensive repairs or replacements are necessary, it is advisable to seek expert advice to prevent potential mishaps, thereby safeguarding the longevity and efficiency of the solar system.

In conclusion, the successful repair of a solar automatic mixing valve demands a comprehensive understanding of the valve’s role, potential issues, proper tools, and approaches to diagnosis and execution of repairs. Engaging in periodic maintenance solidifies a sustainable approach towards ensuring that the valve operates correctly, which in turn influences the entire solar heating system’s efficacy.

By establishing a repair procedure that begins with a detailed assessment and follows through with diligent maintenance, homeowners can appreciate the value their solar systems provide. Investing time into understanding the valve’s functionality allows for a proactive rather than reactive approach to repairs, ultimately promoting system longevity.

In situations that exceed direct repair capability, understanding when to rely on professionally qualified technicians guarantees that a properly functioning solar automatic mixing valve enhances system performance and maximizes energy efficiency. Overall, being informed on the workings of such critical components fosters a more harmonious relationship between homeowners and their solar energy systems, ultimately leading to substantial long-term benefits.

Should individuals choose to pursue DIY repairs, they must remain cognizant of the intricate nature involved and prioritize learning more about their specific valve systems to execute effective repairs. Taking responsibility for maintenance not only empowers homeowners but significantly enhances the efficiency and reliability of their energy systems, ultimately fostering a more sustainable approach to energy consumption.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-repair-the-solar-automatic-mixing-valve/