To repair a deformed solar tank, follow these crucial steps: 1. Assess the damage thoroughly, including looking for leaks and structural integrity issues, 2. Drain the tank carefully to manage any residual water, 3. Apply necessary heat or mechanical force to restore the shape, 4. Seal any leaks or openings caused by deformation and test for stability. Ensure the materials used for repairs are weather-resistant and suitable for prolonged exposure to heat and pressure. Each step is vital for ensuring long-term functionality and safety.

1. UNDERSTANDING SOLAR TANK DEFORMATION

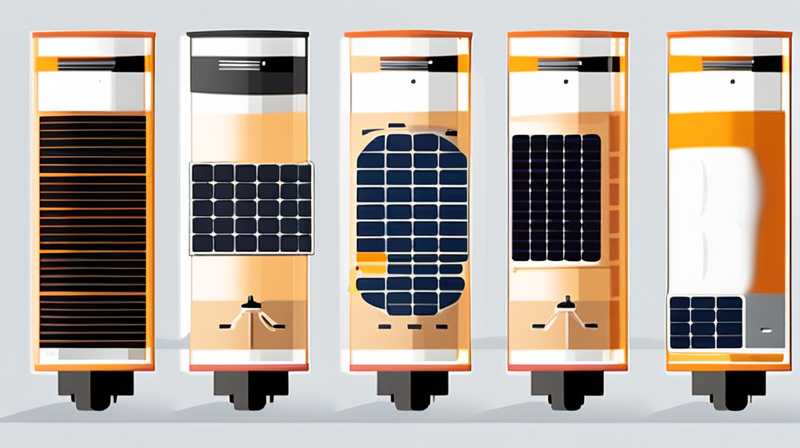

The significance of a solar tank in energy systems cannot be understated. It stores hot water generated through solar energy, thus enabling efficient energy use in homes and commercial setups. Deformation of these tanks can arise from several factors, including improper installation, excessive temperature fluctuations, or manufacturing defects. Understanding the underlying causes of deformation is essential in outlining an effective repair strategy.

Beyond the immediate impact on functionality, a deformed solar tank may lead to increased energy costs due to inefficient heating. Moreover, the presence of leaks can lead to water damage in adjacent structures, potentially resulting in considerable repair costs. Gaining insights into the deformation’s nature can significantly influence the repair process.

2. INITIAL ASSESSMENT OF DAMAGE

Before embarking on the repair process, it is imperative to conduct a thorough evaluation of the tank’s condition. Inspection should cover the entire surface area to identify visible deformities, leaks, or signs of corrosion. Utilizing tools such as pressure gauges can help ascertain whether the tank maintains its intended pressure levels, thereby revealing hidden issues not immediately visible to the naked eye.

Observing any signs of wear or stress, such as bulging or cracking, is crucial. During this phase, documentation of all observed issues should be noted, as this information serves as a guideline for subsequent repair steps. If issues are significant, consulting with professionals in solar technology may be beneficial, as they can provide insight or direct assistance tailored to the specific issues at hand.

3. DRAINING THE TANK

Once the damage is assessed, the next critical step involves the careful draining of the tank. Draining ensures that there is no residual water that could complicate the repair process. This task should be executed with caution to prevent any accidents or water damage to the surrounding area. Utilizing valves and drains designed for such operations can facilitate a smooth drainage process.

After the tank has been drained, it is advisable to clean the interior thoroughly. Any accumulation of sediment or contaminants can impede repairs and potentially affect the tank’s operational efficiency post-repair. Employing cleaning agents that are compatible with the tank’s material can ensure that the surfaces are free from residues that might compromise adhesives or sealants used later in the process.

4. TEMPERATURE AND SHAPE RESTORATION

Restoring the tank to its original shape may involve applying heat or mechanical force. The method chosen will largely depend on the extent of the deformation. If the tank’s material can withstand it, employing a heat source can make the material pliable, allowing for reshaping. This process requires a careful approach to avoid overheating, which can further compromise structural integrity.

In instances where heat is not a viable option, mechanical restoration methods, such as pressing or pulling, can be considered. These techniques may require specialized equipment and should be executed by skilled personnel who understand the nuances of working with specific materials. It is essential to continuously monitor the tank’s condition during this process to avoid causing additional damage.

5. SEALING LEAKS AND OPENINGS

With the tank reshaped, the next task is to address any leaks or openings that may have developed due to the deformation. Sealants specifically designed for high-temperature environments should be selected to ensure durability and effectiveness. Applying these materials involves careful execution; any gaps not sealed properly can lead to future leaks, potentially causing further damage.

After applying the sealant, it is vital to allow adequate curing time as specified by the manufacturer’s instructions. This period is essential for the material to reach its maximum strength before the tank is put back into service. Additionally, once cured, conducting a pressure test will help confirm the integrity of the repair and identify any remaining issues.

6. TESTING AND REINSTALLATION

After completing all repairs, it becomes crucial to test the tank under pressure to ensure that it meets operational standards. Testing protocols should include monitoring for leaks and pressure retention over a specified period. If all checks indicate that the tank functions correctly and maintains its shape, the next step is to reinstall the tank into the solar energy system.

During this reinstallation phase, ensuring that all connections are properly sealed and secured is imperative to prevent future issues. Following manufacturer guidelines for installation best practices will further enhance the system’s efficiency and longevity. After the tank is reinstalled, it is wise to conduct a final inspection before reintroducing water for heating purposes.

7. MAINTENANCE TIPS AFTER REPAIR

Once the solar tank has been repaired and reinstalled, implementing regular maintenance practices is crucial for longevity. Inspection intervals should be established to routinely evaluate the tank’s condition, focusing on potential areas of wear and ensuring that seals remain intact. Furthermore, maintaining a healthy balance in temperatures can prevent future occurrences of deformation.

After a repair, ensuring proper operation involves monitoring energy efficiency and water quality consistently. Water quality can significantly affect the lifespan of the tank, so filtering or treating water as needed should be a priority. Implementing these practices not only enhances the tank’s functionality but also contributes to overall system efficiency.

FREQUENTLY ASKED QUESTIONS

WHAT CAUSES SOLAR TANK DEFORMATION?

Solar tank deformation may stem from various factors such as thermal expansion and contraction, poor manufacturing standards, or improper installation. The impact of extreme temperatures can cause the materials to stress and potentially warp. Additionally, factors like improper system design and inadequate support mechanisms may lead to structural failures. Regular maintenance and adherence to installation guidelines are essential in mitigating these risks.

HOW CAN I DETECT A DEFORMED SOLAR TANK?

Detection of a deformed solar tank can involve visual and functional assessments. Inspecting for visible signs such as bulges or cracks on the surface is critical. Additionally, monitoring any unusual pressure fluctuations during operation can help identify internal structural issues. For comprehensive assessment, consider enlisting professionals who can conduct detailed inspections employing specialized tools to uncover hidden defects.

WHAT SHOULD I DO IF MY SOLAR TANK IS DEFORMED?

Upon discovering a deformity in a solar tank, immediate steps should focus on assessing the extent of the damage. Consequently, detailed inspections will guide you in deciding whether a repair or replacement is necessary. If repairs are deemed feasible, employ a systematic approach involving draining, reshaping, sealing, and thorough testing of the tank post-repair. Consulting with professionals can also provide added insurance for effective handling of the situation.

To ensure the longevity and efficiency of a solar tank, it is paramount to follow a structured repair protocol. First, recognizing the symptoms and cause of deformation sets the foundation for effective action. Proper draining and cleaning prevent complications during reshaping, which is a critical stage in restoration. Sealing any leaks, followed by rigorous testing, confirms that the tank is ready to go back into service. Moving forward, implementing a robust maintenance strategy will support optimal performance and identify any issues before they escalate into more significant problems. By taking these proactive steps, solar tank owners can maximize their investments and harness solar energy’s benefits more effectively over time.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-repair-the-deformed-solar-tank/