1. The process of repairing a broken solar tube involves several distinct steps, including assessing the damage, gathering suitable tools and materials, ensuring proper safety measures, and executing the repair effectively. 2. Identifying whether the issue lies within the structure or the connection is crucial. 3. Utilizing high-quality adhesives or replacement parts can enhance longevity. 4. Lastly, monitoring the repaired solar tube for functionality after completion ensures that it operates efficiently.

1. UNDERSTANDING SOLAR TUBE STRUCTURE

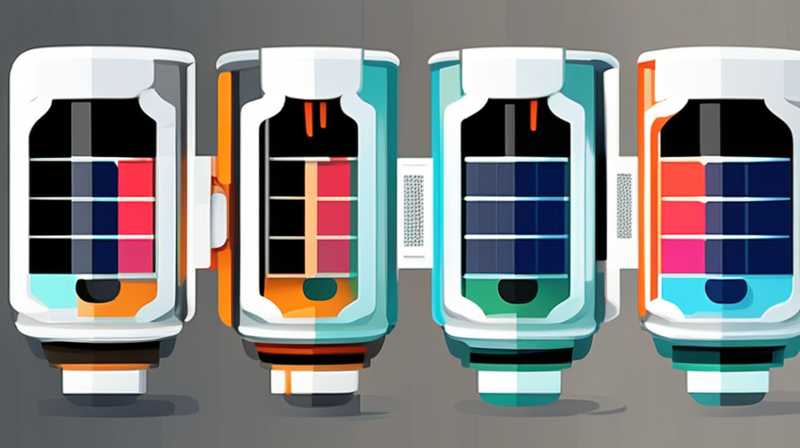

Solar tubes are essential components in solar energy systems, designed to harness sunlight and convert it into usable energy. The structure typically consists of a sealed cylindrical tube filled with a special gas. This technology efficiently captures and transmits solar energy. When addressing concerns related to their durability, it is vital to understand the construction materials that influence their resilience. Common materials used include tempered glass and high-grade plastics, which each carry unique attributes that determine their effectiveness.

The effectiveness of a solar tube directly correlates with its design and material quality. For instance, a glass tube may offer superior durability against environmental factors such as hail or strong winds, while plastic tubes provide lightweight characteristics and ease of installation. Understanding the strengths and weaknesses of different materials is key before undertaking repair or replacement—especially if adverse weather conditions are frequent in the area where the solar tube is installed.

2. EVALUATING DAMAGE

Before embarking on repair efforts, an accurate assessment of the broken tube is crucial. Various forms of damage can occur, including cracks, leaks, or complete breaks. Pinpointing the precise nature of the issue can lead to more effective solutions. Inspect visually for any visible cracks or discontinuities. Areas where light does not pass through the tube can indicate deeper structural problems. Additionally, check for visible signs of leakage or disconnections, which might suggest a failure in the tube’s sealing mechanism.

Furthermore, this evaluation should extend beyond mere physical inspection. Testing the solar tube’s performance—evaluating heat output and energy collection—will provide essential insights into the efficiency and effectiveness of the system. Recognizing whether the problem is isolated to the tube itself or if other components, such as connections, are compromised will aid in choosing the appropriate repair method.

3. GATHERING TOOLS AND MATERIALS

Sourcing the right tools and materials paves the way for successful repairs. It’s essential to gather both basic and specialized tools, which may include screwdrivers, wrenches, adhesive sealants, and replacement components. A reliable set of tools will ensure that the repairs can be accomplished efficiently without the need for repeated trips to a hardware store.

In selecting materials, high-quality adhesive sealants are paramount. Choosing an adhesive designed for outdoor use provides the durability needed to withstand temperature fluctuations and moisture. Individuals should consult manufacturers’ specifications to choose the right product. Also, for tube repairs, purchasing replacement segments or kits that match the existing solar tube design enhances repair integrity.

4. ENSURING SAFETY MEASURES

Matter of safety should never be underestimated during any repair task. Working with solar technology involves electrical components and glass that can break easily. Before beginning any repair work, donning protective eyewear and gloves is highly recommended. Ensuring a safe work environment by clearing the area of unnecessary items also plays a role in minimizing risks.

Additionally, understanding the basic principles of electrical safety is vital when dealing with solar systems. Disconnecting the solar panel connections before making repairs ensures no accidental shocks occur. Adhering to safety guidelines not only safeguards the individual performing the repair but also extends the lifespan of the solar tube’s components.

5. PERFORMING THE REPAIR

Execution is the primary stage where collected tools and materials are put to use. Begin by carefully isolating the damaged section of the tube. If a crack is present, cleaning the area with a suitable solvent can ensure that the adhesive bonds effectively. If the damage requires a segment replacement, use appropriate tools to disconnect the tube gently from any fittings.

Once the repair site is prepped, apply the chosen adhesive sealant according to the manufacturer’s instructions. For replacement segments, ensure a snug fit to prevent future leaks or damage. Remaining patient during the curing process of the adhesive is essential—allowing ample time for it to set and bond will ultimately affect the longevity of the repair effort.

6. MONITORING FUNCTIONALITY AFTER REPAIR

Monitoring the repaired solar tube post-repair is fundamental to evaluating the effectiveness of the efforts made. Regular checks for signs of moisture accumulation can identify issues early on. In addition, it is advisable to observe the energy output for improvements over the next several weeks.

Conducting routine evaluations will help to determine whether the repair has restored the solar tube’s full functionality. In cases where repair attempts fail, it may be necessary to consider expert assistance or complete replacement options to safeguard energy collection efficiency.

FREQUENTLY ASKED QUESTIONS

WHAT COMMON ISSUES CAN OCCUR WITH SOLAR TUBES?

Solar tubes can experience various problems, including leaks, cracks, and inefficiencies in energy capture. Over time, aging materials may degrade or fail due to exposure to environmental elements. Additionally, improper installation can lead to air leaks or disconnections in the system, affecting overall performance. Routine maintenance can help identify potential problems early, enabling timely repairs.

HOW CAN I EFFECTIVELY MAINTAIN MY SOLAR TUBE SYSTEM?

To ensure your solar tube system remains in peak condition, regular cleaning is essential. Dust accumulation on the panels can severely diminish efficiency. Using a soft brush or gentle hose spray can help remove debris without causing damage. Annual inspections to assess and repair any structural defects can prolong the lifespan of the system. Monitoring energy output will also assist in detecting any irregularities.

WHEN IS IT TIME TO CONSIDER REPLACEMENT INSTEAD OF REPAIR?

In certain scenarios, the extent of damage may warrant a complete replacement rather than attempting repairs. If the structural integrity of the solar tube is compromised significantly, or if there are repeated issues occurring frequently after multiple repair attempts, it may be more economical to replace the system. Consulting with a professional installer can provide guidance on the best course of action.

In summary, addressing broken solar tubes requires a methodical approach that encompasses evaluation, careful execution of repairs, and a commitment to monitoring performance. Analyzing the damage guides the selection of appropriate tools and materials necessary for effective repair. Understanding the importance of safety throughout the process assures that the work is both efficient and secure. Successful repairs subsequently yield benefits in energy efficiency, allowing solar tubes to continue harnessing renewable energy effectively. Keeping a close watch on the performance after repair highlights any potential issues that might arise post-fixation, ensuring that the solar system maintains its intended functionality. Long-term investment in maintenance and timely repairs will enhance the overall lifespan and efficiency of solar tube systems, making them viable solutions for sustainable energy collection. Ultimately, well-maintained solar technologies contribute to advancing energy independence and promote environmental stewardship for future generations.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-repair-the-broken-solar-tube/