Repairing a solar valve requires specific steps and insights into the system’s functionality. 1. Identification of the issue is crucial, 2. Assessment of the components is necessary, 3. Tools and materials must be prepared, 4. Step-by-step repair is essential for a successful outcome. Understanding the working mechanisms of the solar valve and recognizing signs of malfunction will guide you through the intricate repair process. Dealing with leaks, inconsistent pressure, or complete failures are common scenarios that necessitate careful examination. Proper troubleshooting not only ensures the repair is effective but also extends the lifespan of the solar heating systems. In-depth knowledge and hands-on experience with solar technology can greatly influence the effectiveness of the repair approach.

1. UNDERSTANDING THE SOLAR VALVE

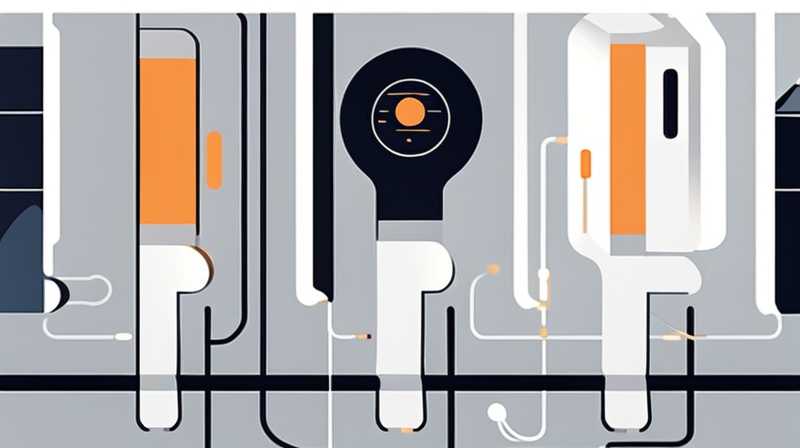

Solar valves play a pivotal role in solar thermal systems, regulating the flow of heat-transfer fluid between collectors and storage. Grasping the fundamental workings of these components is indispensable for competent repairs. The primary function of a solar valve is to control the temperature of the water being heated by solar collectors, preventing overheating and ensuring efficient energy transfer.

These valves often involve mechanical or electrical components that actively respond to temperature changes. A mechanical valve might rely on a bimetallic strip or a wax motor, whereas a more advanced electrical valve uses temperature sensors and electric actuators. Knowing how each part contributes to the system’s overall efficiency is key to diagnosing problems accurately. An understanding of this interplay can help in determining the right methods for repair and assurance of optimal performance post-repair.

1.1 SIGNS OF MALFUNCTION

Identifying problems early can significantly mitigate the repair process’s complexity. Typically, indicators include reduced heating efficiency, leaks, and unusual noises emanating from the valve or nearby piping.

In some cases, users might notice fluctuations in temperature, suggesting that the valve isn’t functioning properly. A gradual decrease in hot water availability may also point towards a valve that does not open or close as required. Recognizing these symptoms early allows for timely interventions and repairs, preventing more severe damage and ensuring continued operational efficiency.

1.2 COMMON ISSUES IN SOLAR VALVES

Solar valves might encounter a variety of problems, making a thorough diagnostic approach essential. Common issues include wear and tear due to temperature fluctuations, sediment build-up, and seal degradation, which can lead to leaks.

Mechanical failures can ensue from continuous cycling of the valve as it opens and closes, leading to various wear patterns. Sediment can accumulate over time, obstructing the flow and affecting performance. Additionally, seals and gaskets can deteriorate, contributing to leaks that compromise the entire system’s efficiency. Understanding these aspects provides a solid foundation for effective troubleshooting strategies.

2. PREPARING FOR REPAIR

Before embarking on the repair process, adequate preparation is necessary. Having the proper tools, spare components, and a solid understanding of the system layout is paramount.

Tools such as wrenches, screwdrivers, pliers, and torque wrenches should be part of your toolkit. Depending on the specific valve being addressed, you may also require specialized diagnostic equipment like manometers or thermometers to measure pressure and temperature accurately. Moreover, acquiring replacement parts beforehand can streamline the repair process, as delays in sourcing components can prolong downtime.

2.1 GATHERING TOOLS AND MATERIALS

A comprehensive approach to gathering tools is important for an efficient repair. Essential items include a variety of hand tools, safety equipment, and possibly electronic measuring instruments.

Standard hand tools are typically sufficient for most solar valve repairs, allowing for disassembly and reassembly of components. Safety gear, such as gloves and goggles, should be employed to protect against accidental injuries. Moreover, if specialized components need replacement, knowing where to source these from—be it local hardware stores or online suppliers—can save valuable time during repairs.

2.2 SAFETY PRECAUTIONS

Safety measures cannot be overstated in any repair situation, especially when dealing with pressurized systems containing hot fluids. Ensuring that the system is depressurized before commencing work is essential to prevent accidents such as burns or other injuries.

Additionally, wearing appropriate protective equipment minimizes the risk of injury from sharp edges or accidental contact with hot components. Familiarizing oneself with the solar system’s design and potential pitfalls can significantly mitigate risks during the repair. Adhering to safety protocols promotes not only a safer work environment but also instills confidence in the repair process.

3. STEP-BY-STEP REPAIR PROCESS

The methodical execution of repair tasks will significantly enhance the likelihood of success. First, isolate the solar valve from the system, then proceed to remove it carefully without damaging connecting pipes or components.

Begin by shutting off the flow of fluid to and from the valve. Depending on the layout, this might necessitate the use of manual shut-off valves. Once isolated, drain the water or fluid from the immediate pipeline to prevent spillage. Following this, utilize appropriate tools to detach the solar valve, taking care to remember the sequence of disassembly for efficient reassembly later.

3.1 INSPECTING AND CLEANING

Once the valve is removed, a comprehensive inspection is in order. Look for signs of wear, damage, or any blockages in the valve mechanism itself.

In many instances, routine cleaning can resolve minor issues such as sediment build-up. Use a soft brush and vinegar to clean internal components without damaging them. Pay special attention to seals and gaskets for signs of deterioration; replacing these can often resolve leak issues without needing to overhaul the complete system.

3.2 REPLACING COMPONENTS

If any components are irreparably damaged, replacement is necessary. Sourcing the correct parts is crucial, as mismatched or inferior-quality replacements can cause further issues.

Utilize manufacturer specifications to ensure part compatibility. When replacing parts like O-rings, diaphragms, or the valve itself, proper installation is critical. Ensure that all components fit snugly and are installed correctly to prevent leaks or premature wear. Taking the time to ensure quality replacements guarantees a more durable and efficient repair.

4. REASSEMBLY AND TESTING

Completing the repair process necessitates careful reassembly. Follow the disassembly steps in reverse order, ensuring that all connections are secure and sealed appropriately.

Once the valve is reattached, open any shut-off valves slowly to reintroduce pressure into the system. Observe the valve for any leaks or abnormal behaviors. It’s vital to monitor operational parameters, such as flow rates and temperatures, to ensure that the solar heating system functions correctly. A successful repair should result in restored performance levels, affirming all repairs made.

4.1 FINAL CHECKS

Conduct thorough checks throughout the operational parameters to assess the efficiency of the repair. This includes monitoring temperature variations and ensuring that the valve responds correctly under various conditions.

Check for any unusual noises or vibrations after reintroducing fluid into the system. If issues persist, consider a reassessment of the repair undertaken, particularly focusing on the components that were replaced. An ongoing evaluation may be crucial for long-term success, ensuring all parts are functioning harmoniously within the solar heating system’s design parameters.

4.2 MAINTENANCE AND CARE

Post-repair maintenance plays a vital role in the longevity of the solar valve and overall system. Great care should be taken to implement periodic inspections and maintenance routines to prevent future issues.

Implementing a regular schedule for inspection can help in identifying potential problems before they escalate. Additionally, keeping the solar collectors clean and the fluid free of sediments maintains efficient energy transfer. Such proactive measures significantly enhance the reliability and efficiency of the solar heating system over its lifespan.

FREQUENTLY ASKED QUESTIONS

HOW OFTEN SHOULD SOLAR VALVES BE SERVICED?

Regular maintenance plays a crucial role in ensuring the longevity and efficiency of your solar heating system’s components. Valves should be checked at least once a year, ideally before the heating season begins. During these inspections, any signs of wear, potential leaks, and sediment build-up should be evaluated. If the system is exposed to harsh environmental conditions, or if it operates significantly over time, more frequent checks may be warranted. By conducting routine maintenance, you minimize the chance of unexpected failures and extend the lifespan of the system, ultimately safeguarding your investment.

WHAT ARE THE COMMON CAUSES OF SOLAR VALVE FAILURE?

Solar valve failures often stem from wear and tear due to thermal cycling, dirt or sediment accumulation, or deterioration of seals and gaskets. Mechanical valves might fail to actuate due to a malfunction in the mechanism responsible for temperature sensing or flow control. Electrical valves may also experience failures due to issues with wiring, power supply, or the control unit. Environmentally induced factors, such as extreme temperatures or corrosive fluids, can exacerbate these problems and lead to premature failures. Understanding these causes is essential for preventive maintenance and effective repairs.

CAN I REPAIR A SOLAR VALVE MYSELF?

Undertaking repairs on a solar valve can be feasible for those with a fundamental understanding of plumbing and mechanical systems. However, various factors must be taken into account, such as the complexity of the valve and your familiarity with solar technology. Proper research, tools, and safety precautions are necessary before attempting repairs. If the issue is straightforward, a DIY approach can save costs. For intricate problems or if you’re unsure, consulting with a professional technician experienced in solar heating systems is advisable. Their expertise might prevent potential errors that could exacerbate issues.

In summary, repairing solar valves requires a methodical approach, accentuating the understanding of the components, careful preparation, and diligent follow-through. Following a structured process enhances the likelihood of successful repair outcomes, ensuring the continued efficiency of solar heating systems. Knowledge of common issues, safety precautions, and routine maintenance practices build a reliable foundation for effective problem resolution. By paying attention to the crucial aspects outlined, individuals can take charge of their solar technology, prolonging its life and maximizing energy efficiency. Ultimately, a proper understanding of repair can mitigate costs and enhance one’s competence in handling solar energy systems.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-repair-solar-valve/