To repair solar tube foam, follow these essential steps: 1. Assess the damage thoroughly to determine the extent of the repairs needed, 2. Gather necessary materials such as foam adhesive, replacement foam, sealant, and safety equipment, 3. Carefully remove the damaged foam from the solar tube without harming surrounding components, 4. Apply the new foam or adhesive and ensure a proper fit, 5. Seal the edges effectively to prevent future leaks or insulation loss. Elaboration on the first point: assessing the damage is vital; effective repairs depend on understanding whether the foam is cracked, deteriorating, or wholly missing. A detailed evaluation informs the necessary approach for replacement and ensures that all issues are addressed.

1. UNDERSTANDING SOLAR TUBE FOAM

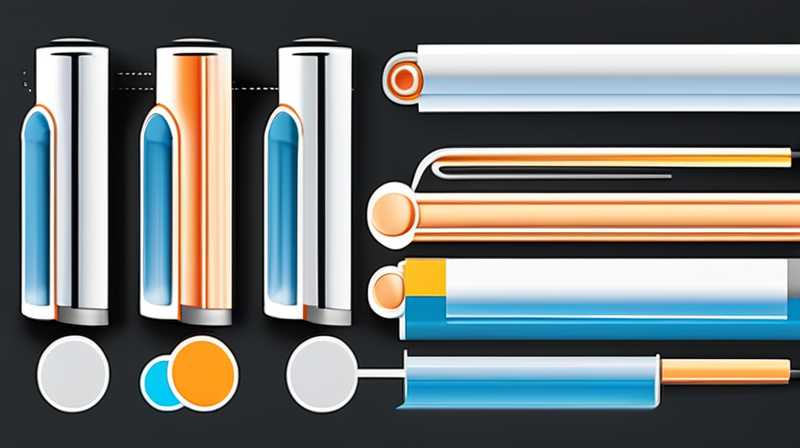

Solar tubes are innovative solutions for harnessing natural light while minimizing energy costs. The foam utilized in these systems serves as insulation and protection against environmental factors. Properly functioning foam ensures the efficiency of the solar tube by preventing heat loss and condensation. As time wears on, various elements can compromise the integrity of the foam, making timely repair imperative. A thorough understanding of the role of solar tube foam can facilitate better maintenance and repair choices.

The performance of the solar tube is directly impacted by the condition of its foam insulation. Even minor degradation can lead to significant energy losses and increased utility costs. Environmental conditions such as moisture, temperature fluctuations, and exposure can lead to wear and tear. Therefore, grasping these implications fosters proactive repair measures that enhance the longevity and efficiency of solar tubes.

2. IDENTIFYING DAMAGE IN SOLAR TUBE FOAM

Before undertaking repairs, one must adequately identify the extent of the damage. Close inspection is crucial to discern whether the foam shows signs of cracking, peeling, or other forms of degradation. Various techniques can be applied to evaluate the condition effectively. For instance, visual and tactile assessments can reveal compromised areas that might not be readily visible.

Another aspect to consider is the environmental factors influencing foam health. Locations experiencing extreme weather tend to have more prevalent damage. Conditions like high humidity can accelerate deterioration because moisture seeps into the foam, leading to mold growth. Such an understanding equips individuals with the knowledge needed to conduct thorough assessments, paving the way for effective repairs.

3. GATHERING REPAIR MATERIALS

Effectively repairing solar tube foam necessitates the right materials. Several essential items should be included in the toolkit: foam adhesive, replacement foam, a sealant, safety goggles, and gloves. Each component plays a significant role in ensuring a professional and lasting repair job.

The selection of foam adhesive is crucial since not all adhesives are suitable for foam materials. It is essential to choose an adhesive specifically designed for foam applications to ensure a strong bond. Likewise, the type of replacement foam should match the original material closely to maintain insulation quality. Finally, having safety equipment like gloves and goggles protects against any potential irritants, ensuring the repair process remains safe and efficient.

4. REMOVING DAMAGED FOAM

Once the necessary tools and materials are on hand, the next phase involves carefully removing the damaged foam from the solar tube. Taking the time to perform this step meticulously is vital. This process often requires cutting away the compromised foam without causing harm to the underlying structure or insulation.

Employing a sharp utility knife or scissors can facilitate the removal process. Light pressure should be applied to avoid damaging surrounding areas. Additionally, it may be helpful to clean the surface beneath the foam to ensure a strong bond with the adhesive used during repairs. Once the damaged foam has been removed, ensuring that the surface is smooth and free from debris forms a critical foundation for applying new foam.

5. INSTALLING REPLACEMENT FOAM

With the damaged foam successfully extracted, focus shifts to installing the replacement material. Begin by measuring and cutting the new foam to fit snugly within the designated area. It is essential to ensure that the new foam matches the dimensions of the original to attain the intended insulation effectiveness.

A layer of foam adhesive must be applied evenly to both the foam and the solar tube surface. This ensures a solid bond and proper insulation. Once the adhesive is applied, securely press the foam into place, adhering it to the solar tube. Allow adequate time for the adhesive to cure as specified by the manufacturer’s instructions to guarantee a lasting repair.

6. SEALING AND FINISHING TOUCHES

After the new foam is installed, the next significant step is sealing the edges. Sealing helps prevent moisture infiltration and further degradation of the foam. A high-quality sealant is recommended for this process and should be applied thoroughly around the perimeter of the newly installed foam.

Moreover, assessing the surrounding area for additional leaks or vulnerabilities is wise. Conducting a comprehensive maintenance check can ensure that any potential issues are addressed simultaneously. Completing the sealing process enhances the solar tube’s durability and performance, contributing to its overall functionality.

7. MAINTAINING SOLAR TUBE FOAM POST REPAIR

Following the repair, ongoing maintenance remains paramount in ensuring the longevity of the new foam. Regular inspections and prompt attention to any emerging issues can help sustain the effectiveness of the repair job. It is advisable to schedule periodic reviews of the foam insulation and surrounding areas to check for any signs of damage.

Additionally, environmental considerations should continue to inform maintenance practices. For instance, areas prone to high humidity may require more frequent inspections to prevent moisture accumulation. Utilizing preventative measures, including proper drainage and ventilation solutions, can further enhance the resilience of solar tube systems.

8. BENEFITS OF MAINTAINING SOLAR TUBE FOAM

Ensuring the integrity of solar tube foam offers myriad benefits. Effective foam insulation drastically increases energy efficiency, minimizing reliance on artificial lighting and reducing utility costs. Furthermore, maintaining optimal conditions within solar tubes positively impacts the lifespan of the entire system, leading to fewer repairs and replacements required over time.

Incorporating regular maintenance into the schedule not only boosts performance but also contributes to environmental sustainability. Utilizing solar energy effectively reduces carbon footprints and promotes eco-friendly practices. Therefore, the commitment to maintaining solar tube foam is a multifaceted investment yielding both immediate and long-term rewards.

FREQUENTLY ASKED QUESTIONS

WHAT IS SOLAR TUBE FOAM, AND WHY IS IT IMPORTANT?

Solar tube foam serves as insulation material within solar tube systems, ensuring that heat transfer is minimized, and natural light is effectively harnessed. The importance of this foam cannot be overstated; it affects the overall energy efficiency of the structure and maintains the integrity of the natural lighting system. Insulation helps regulate temperatures and prevent condensation, contributing to the durability and performance of solar tubes. Deterioration of foam can lead to significant issues, such as reduced energy efficiency and increased costs. Therefore, understanding its purpose is crucial for effective maintenance and periodic repair to prolong the lifespan of the entire system.

HOW OFTEN SHOULD SOLAR TUBE FOAM BE INSPECTED?

Establishing a routine inspection schedule for solar tube foam is integral to effective maintenance. It is generally recommended to inspect foam annually, although this frequency may increase for areas subjected to extreme climate conditions. Such inspections should involve checking for visible signs of damage, moisture effects, and overall integrity of insulation. Early identification of potential issues is paramount; catching any problems in their infancy can save considerable time and resources in repairs down the line. Additionally, periods of inclement weather may warrant additional checks to ensure the insulation holds up against environmental stresses.

WHAT TO DO IF I CANNOT REPAIR THE DAMAGE MYSELF?

When individuals encounter damage beyond their expertise, seeking professional assistance is wise. Trained technicians possess the expertise necessary to assess the situation accurately and implement effective repair strategies. Consulting professionals helps ensure that the repairs meet industry standards and safety regulations. Moreover, attempting repairs without adequate knowledge can result in further damage and heightened costs. Therefore, reaching out for professional help is a responsible decision that protects the investment made in solar tube systems while ensuring longevity and performance.

Prioritizing the vitality of solar tube foam is vital for sustaining the benefits of solar technology. Engaging in timely repairs and maintenance not only preserves the initial investment but enhances energy efficiency and economic viability over time. A comprehensive understanding of solar tube foam and its attributes guides individuals in navigating the complexities of repair processes effectively. By investing time and effort into the maintenance of the foam, users contribute to a healthier environment and personal savings on energy bills. Properly maintained solar tubes facilitate an abundance of natural light while minimizing ecological footprints. The interplay between correct installation, regular inspections, and prompt repairs keeps solar tube systems functioning optimally. Ultimately, the commitment to upholding these structures speaks volumes about the significance of sustainable practices and energy conservation efforts.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-repair-solar-tube-foam/