How to Repair Solar Solenoid Gate Valve

1. Understanding the Mechanism and Functionality, 2. Identifying Common Issues, 3. Step-by-Step Repair Process, 4. Maintenance Tips for Longevity

Repairing a solar solenoid gate valve involves a systematic approach that identifies the source of the problem and implements effective solutions. 1. Understanding the mechanism and functionality of solar solenoid gate valves is essential. 2. Identifying common issues such as malfunctioning solenoids, leaks, or electrical failures can guide repairs. 3. Implementing a step-by-step repair process ensures a thorough fix. 4. Maintenance tips ensure the valve operates efficiently for an extended period.

1. UNDERSTANDING THE MECHANISM AND FUNCTIONALITY

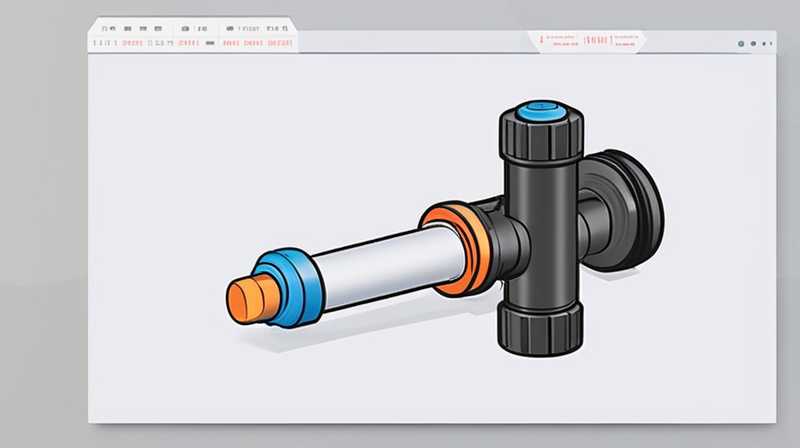

Solar solenoid gate valves are critical components in irrigation and fluid control systems, relying on both solar energy and electrical solenoids to function efficiently. The primary mechanism behind these valves involves the use of a solenoid that, when energized, creates a magnetic field that either opens or closes the valve. This feature enables automated irrigation systems to operate without the need for direct power sources, making them highly effective and eco-friendly.

When a solar solenoid gate valve is functioning optimally, it provides seamless control over water flow, which is particularly advantageous in agricultural or landscaping applications. It simplifies the management of resources, allowing users to program specific schedules for irrigation, thus conserving water. However, understanding the signs of malfunction is imperative, as compromised valves can disrupt water supply and lead to inefficiencies. A comprehensive knowledge of the installation, operational principles, and troubleshooting methods is necessary for anyone tasked with maintenance or repairs.

2. IDENTIFYING COMMON ISSUES

Recognizing the potential issues that can arise with solar solenoid gate valves will greatly aid in the repair process. Some frequent problems include solenoid malfunctions, valve leaks, frozen components, and bad electrical connections. Tackling these deficiencies requires a methodical approach to diagnosis, ensuring that the root cause of any malfunction is addressed.

A malfunctioning solenoid may arise due to corrosion, dirt buildup, or electrical faults. These solenoids can become clogged, preventing them from opening or closing correctly. To diagnose such issues, inspect the solenoid coil for visual signs of wear, check for proper voltage using a multimeter, and ensure connections are secure. Leaks are another prevalent issue, often stemming from improper seals or damaged O-rings, necessitating replacement or adjustment to restore integrity.

3. STEP-BY-STEP REPAIR PROCESS

Once the specific issue has been identified, it’s time to implement repairs. The first step involves gathering the necessary tools, including wrenches, screwdrivers, dielectric grease, and replacement parts such as solenoids or seals. Safety measures should also be adhered to, ensuring the system is powered down to prevent electrical shock or accidents.

Begin the repair process by isolating the valve from any power source to ensure safety. Remove the valve cover and inspect the internal components for damage. If the solenoid appears damaged, proceed to disconnect the electrical leads and pull the solenoid from its housing. Examine it closely, replacing it if necessary. In instances where leaks are discovered, identify the source—be it a failing seal or a cracked body—and make the required replacements.

Reassemble the gate valve, ensuring all components are properly aligned and secured. After assembly, re-establish electrical connections and restore power gradually, monitoring for any signs of malfunction during initial use. Routine testing of the valve post-repair is crucial to ensure functionality and prolong the life of the system.

4. MAINTENANCE TIPS FOR LONGEVITY

For sustained performance of solar solenoid gate valves, regular maintenance practices cannot be overlooked. Taking proactive measures not only helps avoid extensive repairs but also enhances the overall functionality of the system. Establishing a maintenance routine that includes periodic inspections, cleanliness, and timely parts replacement is essential.

Begin by routinely clearing debris and soil around the valve to prevent clogging and corrosion. Additionally, inspect the electrical connections for wear and ensure that the solenoid is functioning correctly by testing the voltage outputs. In the off-season or periods of minimal use, consider winterizing the valve to prevent freeze damage, especially in colder climates.

Moreover, keeping records of maintenance actions, repairs, and changes made can aid in recognizing patterns of wear and inform future service schedules. Implementing these preventive strategies will not only extend the lifespan of the valve but also facilitate enhanced irrigation efficiency in the long run.

FAQs

WHAT IS A SOLAR SOLENOID GATE VALVE?

A solar solenoid gate valve is a type of valve used in fluid control systems that operates using an electric solenoid powered by solar energy. These valves allow for automated opening and closing mechanisms, facilitating irrigation and water management without reliance on a traditional power source. The valve works on the principle that when a current passes through the solenoid coil, it creates a magnetic field that actuates the valve, either permitting or restricting flow. This technology is especially beneficial in remote areas with limited access to conventional energy sources, promoting sustainable practices in agriculture and irrigation management. Maintenance is essential to ensure proper functionality, as any malfunction can lead to inefficient water management.

HOW DO I TROUBLESHOOT A MALFUNCTIONING SOLENOID?

If a solenoid does not function as expected, first check the power supply and connections to ensure voltage is reaching the solenoid. Use a multimeter for accuracy. If power is confirmed, inspect the solenoid for physical signs of wear or corrosion. Cleaning the component and ensuring a secure fit often resolves issues. In cases where the solenoid appears damaged or does not function even with proper voltage, replacement of the solenoid may be necessary. It is also advised to check the valve for debris or clogs that could be causing the malfunction, as the flow of fluid may affect solenoid operation.

WHAT ARE THE SIGNS THAT MY SOLENOID VALVE NEEDS REPAIR?

Several indicators suggest that a solenoid valve may require repair. Common signs include physical leaks around the valve, inconsistent water flow, or the inability to open or close the valve entirely. Additionally, if the valve emits unusual noises during operation or if the connected irrigation system shows signs of malfunctions, it may warrant further inspection. Other warning signs may involve increased energy consumption due to electrical issues with the solenoid or visible corrosion on components. Routine inspections are crucial for early detection of these issues, thereby preventing more significant repairs down the line.

Ensuring the performance and reliability of solar solenoid gate valves is paramount in retaining the efficacy of irrigation systems. Adopting a meticulous approach to both repairing and maintaining these integral components will ultimately lead to a well-functioning setup that minimizes water waste while maximizing efficiency. Understanding the intricacies of their operation, alongside identifying signs of wear and promptly addressing them, results in prolonged service life and reduced long-term costs. Recognizing that these components rely heavily on both mechanical integrity and reliable electrical function emphasizes the need for regular service checks. Additionally, embracing preventative measures can significantly boost operational reliability.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-repair-solar-solenoid-gate-valve/