1. Repairing a solar lantern circuit can be accomplished through a series of systematic steps, ensuring functionality is restored efficiently. 2. Always begin by diagnosing the issue, as many problems can stem from similar sources such as battery failure, defective solar panels, or faulty connections. 3. An essential step is to refer to the correct circuitry schematic for the specific lantern model, as variations exist across different designs. 4. Finally, while having basic electronic tools on hand is critical, safety precautions should never be overlooked during the repair process.

1. UNDERSTANDING THE SOLAR LANTERN CIRCUIT

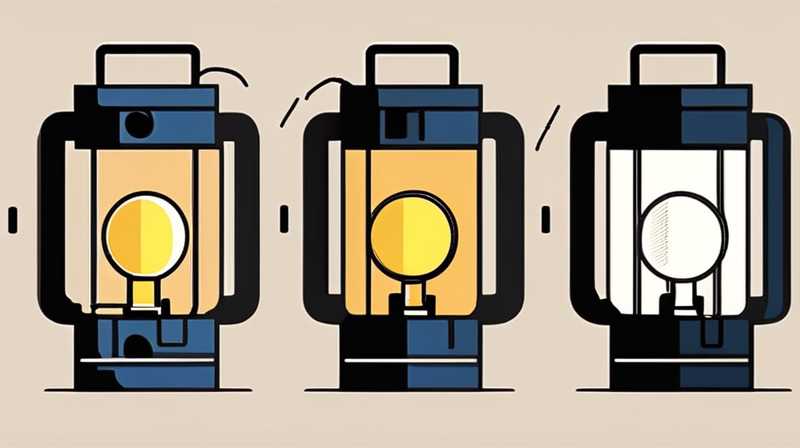

Solar lanterns are innovative devices that harness solar energy, converting it into electrical energy to power LED lights. At the heart of a solar lantern lies a circuit comprising several components, including solar panels, batteries, charge controllers, and LED bulbs. Understanding how each component functions is essential for troubleshooting issues effectively.

The solar panel is responsible for converting sunlight into electricity. When sunlight strikes the solar cells, it generates direct current (DC) electricity. This electricity is then routed to a rechargeable battery, where it is stored for later use. The charge controller regulates the voltage from the solar panel to prevent overcharging the battery, which can lead to diminished battery life or even failure. Finally, the LED bulb illuminates when electrical current flows from the battery through the circuit.

In essence, solar lanterns rely on a delicate balance between these components. When one element malfunctions, it can disrupt the entire system. Understanding this interaction is the first step towards effectively diagnosing and repairing a faulty solar lantern circuit.

2. DIAGNOSING THE PROBLEM

Before initiating any repair efforts, a thorough diagnosis is warranted. Identifying the precise issue can streamline the repair process and prevent unnecessary replacements. Common symptoms of a malfunctioning solar lantern include dim lighting, total inoperability, or irregular flickering.

To diagnose the problem, begin by examining the solar panel. Look for visible damage, such as cracks or dirt accumulation, which can impede the panel’s ability to absorb sunlight. A multimeter can be employed to measure voltage output during sunlight exposure. A significant drop in voltage indicates a probable fault within the solar panel.

Another vital component to inspect is the rechargeable battery. Batteries exhibit degradation over time, and this can lead to inadequate power storage. Removing the battery for testing is advisable. Utilize a multimeter to determine the battery’s voltage; if the voltage is substantially lower than the rated capacity, it may need replacing.

3. TOOLS REQUIRED FOR REPAIR

Repairing a solar lantern circuit typically necessitates a selection of specialized tools. Having the right instruments at your disposal can significantly affect the ease and efficiency of the repair process. A basic toolkit might include a multimeter, soldering iron, wire strippers, and various replacement components.

The multimeter serves as a diagnostic tool, measuring voltage, current, and resistance throughout the circuit. It is instrumental in identifying both live and dead connections within the solar lantern. Soldering irons are crucial for making secure connections among circuit components, especially if wires have become disconnected or corroded.

Wire strippers assist in preparing cables for connection, ensuring clean and precise leads. Moreover, having spare components on hand, like LEDs, batteries, and solar panels, is prudent. Unforeseen issues can arise, and possessing replacement parts can facilitate a more streamlined repair without recurring delays.

4. REPLACING THE BATTERY

If diagnostic procedures reveal that the rechargeable battery is the source of the problem, a replacement is necessary. During this process, it is critical to ensure compatibility with the solar lantern’s specifications. When choosing a new battery, always refer to the manufacturer’s guidance regarding voltage and capacity.

To replace the battery, first, safely disconnect the old battery from the circuit by unscrewing or unclipping any fasteners securing it in place. Verify that the new battery matches the old one’s dimensions and specifications. Securely connect the new battery to the circuit, ensuring each lead is properly attached to its corresponding terminal.

After installation, charge the new battery under sunlight for several hours before testing the lantern. This ensures that the battery is fully operational and can hold a charge effectively.

5. REPAIRING OR REPLACING THE SOLAR PANEL

If diagnostic assessments indicate a problem with the solar panel, repairs or replacements may be in order. The importance of a functional solar panel cannot be overstated, as it is the primary energy source for the lantern.

When determining whether to replace or repair, assess the panel’s surface for any physical damage. Minor surface scratches can often be remedied with a simple cleaning, while significant breakage may necessitate total replacement. If the decision is made to replace the solar panel, ensure the new panel matches the voltage output of the original.

Upon installation of a new panel, test it by placing it in direct sunlight and using a multimeter to verify output voltage. This step guarantees that the lantern will receive adequate power for operation.

6. ADDRESSING CONNECTION ISSUES

Loose or corroded connections can create significant problems in the functionality of a solar lantern. Identifying these issues is paramount for ensuring the circuit operates effectively. Start by visually inspecting all visible wires and terminal connections for signs of wear or corrosion, which can disrupt the flow of electricity.

If you discover corrosion, clean the affected areas using a fine-grit sandpaper or a wire brush to remove tarnish. After cleaning, reconnect the wires and ensure they are secured tightly. Soldering may be necessary for maintaining strong connections, particularly if broken wires have been located.

Once all connections have been checked and secured, conduct a thorough test of the lantern to ensure it functions as expected.

7. SAFETY MEASURES DURING REPAIR

Implementing safety protocols during the repair of solar lantern circuits is an integral aspect of the process. Working with electrical components carries inherent risks, including electric shock and burns. To mitigate these risks, always disconnect the lantern from any power source before starting repairs.

Wearing appropriate personal protective equipment, such as gloves and safety goggles, is advisable to avoid injury. If soldering is necessary, utilize a well-ventilated space to avoid inhaling potentially harmful fumes.

Additionally, maintaining an organized workspace can reduce the risk of accidents. Place tools and components systematically, ensuring they are easily accessible without cluttering the area.

8. TESTING THE LANTERN POST-REPAIR

Following the completion of all repairs, testing the solar lantern is essential to ensure functionality has been restored. Conducting a series of tests helps confirm that all components are working as intended. Begin by placing the lantern in a sunny location during the day to allow the solar panel to charge the battery fully.

After a sufficient charging period, switch on the lantern to verify that it illuminates properly. Take note of brightness levels and flickering, which may indicate an ongoing issue with the circuit.

If the lantern functions correctly, it is advisable to monitor its performance over several days to ensure there are no recurring problems. Keeping a close eye on the lantern’s performance will help identify future maintenance needs and enhance the overall lifespan of the device.

WHAT ARE THE COMMON ISSUES WITH SOLAR LANTERNS?

Common challenges associated with solar lanterns typically stem from battery issues, solar panel problems, or circuit failures. Batteries often degrade after repeated charge cycles, leading to poor performance or failure to hold a charge. On the other hand, solar panels can become inefficient due to dirt, physical damage, or environmental factors affecting their ability to capture sunlight. Circuit issues may manifest in the form of loose connections or corroded wiring. A thorough examination of each component is crucial for accurately diagnosing the root cause of the malfunction.

HOW DO I MAINTAIN A SOLAR LANTERN FOR OPTIMAL PERFORMANCE?

To ensure that a solar lantern performs optimally, regular maintenance is essential. Key maintenance tasks include cleaning the solar panel, protective housing, and checking battery condition. Dust and grime can accumulate on the solar panel, obstructing sunlight absorption and reducing efficiency. Cleaning the panel with a damp cloth can significantly enhance performance. Additionally, periodic examinations of the battery can help identify early signs of wear or degradation, enabling timely replacements. Regular inspections of connections and wiring can also prevent future circuit issues and promote the longevity of the device.

CAN I REPAIR A SOLAR LANTERN MYSELF?

Yes, many individuals can independently repair their solar lanterns, provided they have basic knowledge of electronics and access to appropriate tools. Empowering oneself with this skill can result in significant cost savings without the need for professional service. However, it’s important to approach repairs with caution. Understanding the circuitry and possessing the necessary tools is vital for efficient repairs. Additionally, one should always prioritize safety by ensuring no power source is connected during the repair process. Documentation of the repair process can also be helpful for future reference and maintenance.

REMEDIATING SOLAR LANTERN MALFUNCTIONS REQUIRES DEDICATION AND CARE. THE PROCESS DEMANDS BOTH TECHNICAL KNOWLEDGE AND ATTENTION TO DETAIL. SUCCESSFULLY IDENTIFYING AND ADDRESSING EACH COMPONENT MAY NOT ONLY RESTORE FUNCTIONALITY BUT ALSO SIGNIFICANTLY EXTEND THE LANTERN’S USEFUL LIFE. IN PARTICULAR, UNDERSTANDING THE ROLE OF SOLAR PANELS, BATTERIES, AND CIRCUIT CONNECTIONS CREATES A COMPREHENSIVE APPROACH TO REPAIRS. BY FOSTERING A CULTURE OF MAINTENANCE AND REGULAR CHECK-UPS, USERS CAN ENJOY CONTINUOUS SERVICE FROM THEIR SOLAR LANTERNS, EVEN IN ENCOUNTERING ODD MALFUNCTIONS. DURING REPAIRS, IT’S ESSENTIAL TO EMPLOY A METHODICAL STRATEGY: ASSESSING THE PROBLEM, SECURING THE NECESSARY TOOLS, AND EXECUTING REPAIRS WITH PRECISION CAN LEAD TO POSITIVE OUTCOMES. NEVER UNDERESTIMATE THE SIGNIFICANCE OF PROTECTIVE MEASURES AND A SAFE WORK ENVIRONMENT IN THIS PROCESS. ULTIMATELY, A WELL-MAINTAINED SOLAR LANTERN DOES NOT JUST ENHANCE ENERGY EFFICIENCY BUT ALSO CONTRIBUTES TO SUSTAINABLE ENVIRONMENTAL PRACTICES, EMBRACING THE USE OF RENEWABLE ENERGY RESOURCES IN OUR DAILY LIVES. ASSURING FUNCTIONALITY ALLOWS FOR RELIABLE LIGHTING SOLUTIONS WHILE REDUCING RELIANCE ON CONVENTIONAL POWER SUPPLIES.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-repair-solar-lantern-circuit-video/