To repair a solar check valve, it is essential to follow a systematic approach: 1. Identify the root cause of the malfunction, 2. Disassemble the valve carefully without losing any parts, 3. Clean all components thoroughly to remove any debris or mineral buildup, 4. Replace worn-out seals or O-rings as needed, and 5. Reassemble the valve, ensuring all parts are correctly positioned and secure. A detailed examination of the sealing mechanisms can significantly enhance the performance and longevity of the solar check valve.

1. UNDERSTANDING SOLAR CHECK VALVES

Solar check valves play a pivotal role in solar thermal systems, functioning to prevent backflow and ensure efficient fluid circulation. Typically installed in liquid-based solar heating installations, these valves are designed to maintain the direction of fluid movement. This selection is crucial for preserving the integrity of the system, especially under varying temperature conditions.

The engineering behind these devices is particularly fascinating as they utilize mechanical principles to facilitate their operations. Within a solar heating system, the relevance of maintaining appropriate fluid pressure and direction is paramount. A failing check valve can lead to significant inefficiencies, resulting in energy loss and increased bills. Thus, comprehending the underlying functionality of solar check valves is a prerequisite for anyone seeking to repair or replace them.

2. COMMON ISSUES WITH SOLAR CHECK VALVES

Multiple issues may arise with solar check valves, which can impair their functionality. One prevalent issue is a stuck valve, which may be caused by debris accumulation or a worn-out spring. When the valve gets stuck in a closed position, fluid cannot circulate as needed, leading to overheating and possible damage to the solar panels. In contrast, if the valve remains open, the system may experience backflow, reducing efficiency and potentially damaging components.

Another common concern involves a leak, typically resulting from degraded seals or improper installation. Leaking check valves can lead to a drop in system pressure, causing inefficiencies and potentially damaging the entire solar setup. Addressing these issues promptly is essential to maintain optimal system performance and longevity. Recognizing these challenges enables users to act swiftly, ultimately extending their solar system’s lifespan.

3. TOOLS REQUIRED FOR REPAIR

Before embarking on a repair journey, acquiring the appropriate tools is crucial for a successful outcome. Essential tools typically include a wrench set, screwdriver set, and pliers. Furthermore, having clean rags and bowls can aid in managing components and fluids during disassembly and assembly.

Moreover, applying a leak detection solution can assist in locating cracks or weak points in the valve. A replacement kit, including seals and O-rings compatible with the specific check valve model, is another invaluable asset. It is advisable to review the manufacturer’s guidelines to ensure that the correct tools and replacement parts are utilized. Having the right equipment at hand not only simplifies the repair process but also enhances the reliability of the repair, ensuring the check valve functions optimally after reassembly.

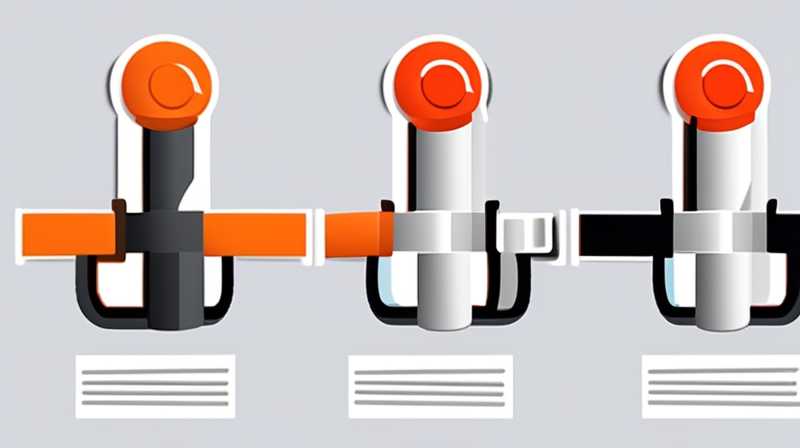

4. STEP-BY-STEP REPAIR PROCESS

To commence the repair of a solar check valve, begin by isolating the valve from the rest of the system. This step is critical to avoid any potential backflow that could lead to a more complex situation. Use wrenches or hand tools to disconnect the valve from the piping. Once it has been isolated, position it on a clean, flat surface for disassembly.

Disassemble the check valve with caution, ensuring to take note of the order and orientation of the internal components. It is beneficial to keep each piece organized to facilitate a smoother reassembly process. After disassembly, inspect each component thoroughly for signs of wear and tear. This examination will help pinpoint specific parts that require repair or replacement, thereby minimizing future issues.

Following the inspection, proceed to clean the internal parts using a mild detergent solution and a soft brush to eliminate any accumulated debris or mineral deposits. After cleaning, allow the components to dry completely before reassembly. Next, replace any worn seals or O-rings to guarantee a tight fit during reassembly. This step is crucial, as compromised seals may lead to leaks after the valve is put back into service.

Upon ensuring that all cleaning and repairs are completed, proceed to reassemble the valve by carefully placing all components back in their original configuration. It is recommended to follow the order of disassembly closely to maintain proper functionality. Once fully assembled, securely reconnect the valve to the piping using the appropriate tools. Double-check all connections to ensure no leaks remain, as proper sealing is vital for the efficient operation of the solar system.

After reinstalling the valve, it is advisable to perform a system check by running fluid through the setup to assess the effectiveness of the repair. Observe for any signs of leakage at the joints or valve itself. Should the valve operate smoothly without obstruction, the repair process can be deemed successful, and the system can resume operation.

5. MAINTENANCE TIPS FOR SOLAR CHECK VALVES

Post-repair maintenance is essential in preventing future issues with solar check valves. Routine inspections should be scheduled every few months, depending on the system’s usage. During these inspections, check for visible signs of wear or leaks around the valve and connections. Additionally, verifying the operational condition of the valve—ensuring it opens and closes freely under normal operating pressure—is critical.

Using proper water treatment solutions can also extend the lifespan of the valve. Hard water can lead to mineral buildup, significantly shortening the valve’s operational life. Incorporating filtration systems or regular maintenance via descaling agents can mitigate this issue. Always consult a professional if unsure about the correct maintenance procedures or if persistent issues occur.

Moreover, keeping an eye on the surrounding environment of the solar installation can prove beneficial. Extreme temperatures can adversely affect the materials used in check valves, and mitigating the impacts of such conditions through insulation or weather protection can prolong the equipment’s functional life. Utilizing high-quality materials and adhering strictly to the installation guidelines can mitigate potential risks associated with equipment failures, ensuring that the system remains efficient and operational for years.

6. COST CONSIDERATIONS FOR REPAIR

Cost is a significant factor when considering repairs on solar check valves, as prices can vary based on several variables. The type of valve, the complexity of the repair, and whether parts need replacement are all factors influencing the overall expense. Understanding the price of components such as seals, O-rings, or even entire assembly replacements is vital before commencing the repair.

Investing in professional repair services might seem like a higher immediate cost, but weighing the long-term benefits can be advantageous. Skilled technicians can often identify underlying issues that might go unnoticed by an untrained individual, thus preventing recurring problems and potentially lower overall costs in the long run.

Additionally, regular maintenance may involve minor costs that accumulate to enhance the entire solar system’s lifespan. Performing routine inspections and cleaning can prevent significant malfunction costs. Therefore, budgeting for routine maintenance and potential repairs is a prudent approach to ensure the continuous efficiency of the solar system.

7. ENVIRONMENTAL IMPACT AND SUSTAINABILITY

The role of solar check valves extends beyond individual systems; their operation contributes to broader environmental sustainability. By ensuring that solar heating systems function optimally through efficient fluid circulation, these valves indirectly reduce reliance on fossil fuels, contributing to a decrease in greenhouse gas emissions.

Moreover, maintaining well-functioning components minimizes waste generated from discarded or damaged parts. By facilitating repairs rather than complete replacements, users can support sustainability efforts while also benefiting economically. The ethos of consuming fewer resources aligns with the principles of sustainability that are paramount in today’s ecological considerations.

To promote sustainability further, encourage the use of high-quality components designed for long-term use within these systems. Education around the importance of regular maintenance can empower users to adopt sustainable practices, leading to more energy-efficient homes and businesses.

8. FUTURE TECHNOLOGIES IN SOLAR CHECK VALVES

As technology progresses, innovations in solar check valves are likely to emerge, enhancing performance and functionality. Future advancements may include smart technologies that allow for real-time monitoring and automated adjustments based on system performance metrics. Such innovations could revolutionize how we manage and maintain solar heating systems, leading to unprecedented efficiency and reliability.

Additionally, the exploration of sustainable materials for solar check valves warrants consideration. Innovations in biodegradable or recyclable materials can help reduce environmental impacts, ensuring that even the components of solar heating systems align with ecological considerations. Exploring these advancements will provide users with a deeper understanding of possibilities for enhancing their systems.

Staying informed about advancements in technology can further empower consumers to select the most innovative solutions for their systems. As a result, they can benefit from the collective knowledge of manufacturers and engineers who continue pushing the envelope for optimal performance in solar heating applications.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE SIGNS THAT A SOLAR CHECK VALVE NEEDS REPAIR?

When it comes to identifying issues with solar check valves, several signs can indicate the need for repair. A stuck valve is one of the most common indicators, where the valve fails to open or close properly, preventing fluid from circulating effectively. This can lead to overheating in solar panels or reduced efficiency. Another significant sign is leaking, where water escapes from the valve’s seals or joints, potentially leading to a drop in system pressure. Additionally, if there is an unusual noise from the valve during operation, it could suggest that internal components have wear or debris that may inhibit normal function. Monitoring system performance closely and being attuned to these signs can help prevent larger issues down the line, ensuring your solar system operates at peak efficiency.

HOW LONG SHOULD A SOLAR CHECK VALVE LAST?

The lifespan of a solar check valve typically ranges from 5 to 15 years, depending on various factors, including the quality of materials used, water chemistry, operating conditions, and maintenance routines. High-quality valves constructed from durable materials generally last longer than cheaper alternatives. Regular maintenance is crucial; performing routine inspections, cleaning out debris, and replacing worn components can significantly enhance the lifespan of the valve. Incorporating a water treatment system to manage mineral buildup can also extend the life of both the check valve and the entire solar heating system. Understanding these variables helps users maintain their systems effectively, preventing premature replacements and ensuring optimal performance over time.

CAN I REPAIR A SOLAR CHECK VALVE MYSELF OR SHOULD I HIRE A PROFESSIONAL?

The decision to repair a solar check valve independently or enlist professional help hinges on several key considerations. If you possess a solid understanding of plumbing systems and specific familiarity with check valves, undertaking repairs independently can be both economical and rewarding. However, if complications arise, or you lack confidence in performing repairs, hiring a professional is advised. Professionals can quickly diagnose underlying problems and implement fixes efficiently, ensuring that the valve operates optimally without risking further damage. Additionally, they often possess the necessary tools and replacement parts readily accessible. Evaluating your own skill set and the complexity of the repair process will assist in making the best decision for your specific situation.

In summary, repairing a solar check valve is a crucial skill for maintaining an efficient solar thermal system. Understanding the potential issues, having the right tools, and following a systematic repair and maintenance process are vital steps. Proper identification of problems such as leaks and stuck valves, alongside familiarity with the tools required, ensures effective and efficient repairs. Routine maintenance after repairs can extend the lifespan of the valve and promote sustainability. Constant advancements in technologies offer a glimpse into the future of solar check valves, promising even better performance and reliability for users. As solar energy continues to grow in importance for both economic and environmental reasons, becoming adept at managing and maintaining these systems is more critical than ever. Investing time in learning about these components will result in significant benefits, both for individual users and for broader sustainability goals.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-repair-solar-check-valve/