1. To repair frozen and cracked solar tubes, follow these steps: 1) Assess the damage thoroughly and ensure that the system is powered down, 2) Identify frozen areas and implement gradual thawing techniques, 3) Inspect cracked tubes for severity and determine whether a patch, sealing compound, or full replacement is necessary, 4) Consider enhancing insulation and protective measures to prevent future incidents. It is paramount to safely navigate the repair process to avoid exacerbating the damage and ensure the continued efficiency of your solar heating system.

1. UNDERSTANDING SOLAR TUBES

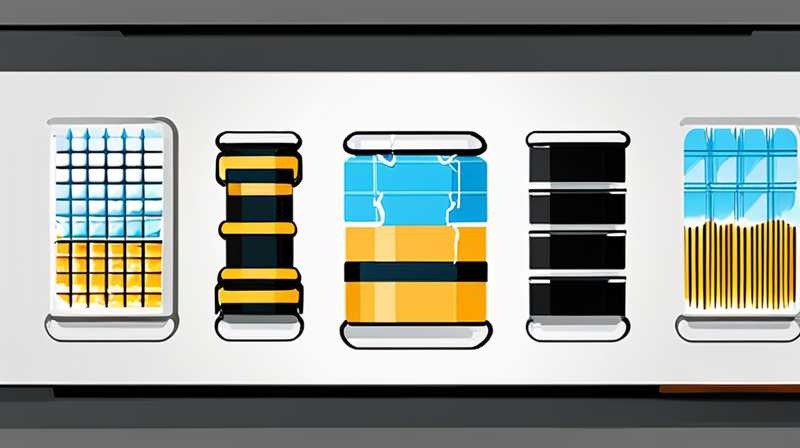

Solar tubes, often referred to as solar tube collectors, are a vital aspect of solar heating systems designed for residential and commercial use. These components harness sunlight and convert it into usable heat energy. It is essential to understand their function and potential vulnerabilities, especially in regions where fluctuating temperatures may lead to freezing concerns. The structure typically comprises a glass tube encasing a vacuum or insulating material, allowing sunlight to penetrate while minimizing heat loss.

Temperature variations can cause significant stress on solar tubes. Abrupt changes can lead to cracks or ruptures, compromising the system’s efficiency. In cold conditions, if the fluid inside freezes, it can expand, leading to severe damage. Recognizing these vulnerabilities allows for proactive measures, enhancing the longevity of solar systems. The importance of preventive maintenance cannot be overstated when dealing with such systems, as it can save homeowners considerable expenses related to repairs or replacements.

2. IDENTIFYING AND ASSESSING DAMAGE

Before initiating repairs, it is crucial to conduct a meticulous assessment of the solar tubes. Inspect for visible indicators of freezing, such as frost build-up, or structural cracks. Examine every tube closely for signs of stress, including hairline fractures or bulging. A thorough evaluation can help determine the extent of the damage and inform decisions regarding repairs. Always ensure that the solar heating system is completely powered down before attempting any assessment.

Additionally, inspect the entire solar system for related issues, such as insulation effectiveness around the pipes or controller settings. It’s also wise to check the fluid type used; certain antifreeze solutions can enhance protection against freezing. If cracks or significant damage are apparent, photographing the affected areas may prove beneficial for future reference, especially if professional guidance becomes necessary. Deferring repairs could result in extensive water damage or permanent system failure, emphasizing the need for prompt action.

3. THAWING FROZEN SOLAR TUBES

When addressing frozen solar tubes, gradual thawing remains the most effective strategy. Applying excessive heat directly to the tube can exacerbate the issue, leading to breakage. Instead, opt for indirect heat sources to gently raise the temperature. For example, wrapping the affected areas with heat tape or using portable heaters can facilitate a slower thaw. Employing a warm water bath could provide additional temperature moderation.

While unfreezing the tubes, it’s essential to monitor the pressure within the system. If a significant pressure increase is noted, pause the thawing process to avoid rupturing the tubes further. As the tubes begin to thaw, assess the fluid’s flow and ensure that any blockage is resolved before reactivating the system. This care and caution during the thawing stage can significantly reduce long-term complications, ensuring that the solar system operates at optimal efficiency once repairs are completed.

4. REPAIRING CRACKED SOLAR TUBES

Once thawing is complete, shifting focus to repairing cracked tubes is paramount. Minor cracks may be addressed with appropriate sealing compounds designed for high-temperature environments. Start by cleaning the damaged area thoroughly, removing any dust and debris that could hinder adhesion. The application of the sealing solution should follow manufacturer instructions carefully, applying it generously to cover the cracks while allowing adequate drying time.

In scenarios where cracks are extensive or compromise structural integrity, tube replacement may be the only viable solution. Replacement typically involves detaching the damaged tube and replacing it with a new one, ensuring that the new component matches the original specifications closely. Professional assistance is advisable for significant repairs to minimize risk and ensure the system is restored correctly. This meticulous attention to detail can prevent further issues down the line, safeguarding the efficiency of solar heating systems.

5. ENHANCING INSULATION AND PROTECTION

Addressing cracks and frozen tube situations also necessitates evaluating the insulation surrounding the solar system. Installing or upgrading insulation can provide a barrier against freezing temperatures, significantly enhancing the durability of the tubes. Adequate insulation around pipes and connections minimizes heat loss and stabilizes internal temperatures to prevent future freeze episodes. Consider materials with high R-values, as they provide superior thermal resistance.

Apart from insulation, additional protective measures should be considered. Installing heat traces along the pipes or automated monitoring systems can provide real-time data on temperature fluctuations. Furthermore, investing in quality weatherproofing for exposed tubes will ensure that they remain intact during adverse weather conditions. Planning ahead regarding insulation and protective measures plays a crucial role in augmenting the longevity of solar tubes and guaranteeing their performance through varying temperature conditions.

6. MAINTENANCE TO PREVENT FUTURE ISSUES

Adopting a proactive maintenance schedule can be indispensable in preserving the integrity of solar tubes. Regular inspections facilitate early detection of potential problems, allowing for timely interventions before significant damage occurs. Homeowners should establish seasonal check-ups, particularly before winter, to examine the integrity of the entire system meticulously.

Moreover, consider flushing the fluid system periodically to mitigate issues related to stagnation or sediment build-up. Implementing more resilient antifreeze solutions can also prove beneficial in extreme climates. Keeping the solar panel area free from snow or ice build-up can further prevent unnecessary strain on the tubes. Ultimately, a comprehensive maintenance plan serves not only to extend the service life of the solar system but also to ensure its effectiveness in providing sustainable energy.

7. FREQUENTLY ASKED QUESTIONS

WHAT ARE THE SIGNS THAT MY SOLAR TUBES ARE FROZEN?

Identifying the signs of frozen solar tubes involves several visual and operational cues. Homeowners may first notice a drop in the performance of their solar heating system, characterized by decreased output and inefficient heating. In extreme cases, frost may be visible on the tubes themselves, indicating freezing has occurred. Additionally, listeners may detect unusual sounds within the system, such as popping or gurgling, hinting at disrupted fluid dynamics caused by freezing. A thorough external inspection may reveal condensation or frost accumulation on tube surfaces, implying inadequate insulation or direct exposure to harsh weather conditions. Assessing the entire system is crucial, as signs may also include pressure gauge readings that deviate significantly from normal operating levels. Regular checks and monitoring can enhance detection and intervention timing, preventing further complications.

IS IT POSSIBLE TO REPAIR CRACKED SOLAR TUBES MYSELF?

Yes, it is feasible to repair cracked solar tubes independently, particularly when dealing with minor cracks. However, it is essential to possess the necessary skills and understanding of the repair materials and methods required. Utilizing appropriate sealing compounds can provide effective solutions for fissures, given the correct application and drying process. Homeowners should ensure that they follow product guidelines meticulously and take safety precautions throughout the repair process, such as ensuring that the system is powered down and allowing adequate drying time before reactivating the system. Nevertheless, significant cracks or extensive damage merit the attention of professional services. Their expertise guarantees that the installation and repairs adhere to operational standards, promoting optimal system functionality. Misjudging the extent of repairs may lead to further complications, emphasizing the importance of prudence in such situations.

HOW CAN I PREVENT FUTURE FREEZING IN MY SOLAR TUBES?

Preventing future freezing in solar tubes requires a multifaceted approach, focusing on insulation, monitoring, and maintenance. Enhancing insulation around the tubes and plumbing can significantly restrict the opportunity for freezing temperatures to reach sensitive areas. Homeowners should consider higher quality or additional insulating materials, and ensuring a snug fit around any exposed plumbing is essential. Furthermore, employing thermal monitoring devices can offer real-time insights into temperature fluctuations, alerting users before a freezing incident occurs. Ensuring regular scheduled maintenance, which includes inspecting and possibly upgrading antifreeze solutions, plays a crucial role in system resilience. Homeowners should also monitor environmental conditions, clearing accumulated snow or ice that may prevent heat retention. Developing a comprehensive plan focused on these areas allows for the proactive management of winter conditions, thereby safeguarding solar systems against freezing.

8. In summary, safeguarding solar tubes necessitates a proactive approach that emphasizes early detection, thorough assessment, and comprehensive maintenance. Repairing frozen and cracked solar tubes can significantly extend the lifespan of solar heating systems and enhance efficiency. The key stages involve recognizing the damage, prudently thawing frozen areas, and effectively sealing or replacing cracked tubes. By adopting preventive measures such as enhancing insulation and employing regular monitoring, the risks of future occurrences can be minimized. Recognizing signs of freezing early and having a clear repair strategy can save considerable time and money, ensuring that solar systems provide dependable and efficient energy. Such comprehensive care and consideration ensure not only the longevity of the solar heating system but also a sustainable energy source for years to come. Investing in the right tools, materials, and knowledge is paramount for both homeowners and professionals to navigate these repairs effectively. This commitment to care fosters an environment where solar technologies can thrive, delivering reliable and sustainable energy to meet rising demands.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-repair-frozen-and-cracked-solar-tubes/