When faced with the challenge of repairing a solar solenoid valve, several crucial steps must be taken to ensure a successful outcome. 1. Identify the issue, recognizing common problems such as leaks, malfunctioning solenoids, or electrical failures. 2. Gather necessary tools and materials, including a replacement solenoid, wrenches, and sealants for leaks. 3. Disassemble the valve carefully, taking care to document each step to avoid confusion when reassembling. Finally, 4. Test the system post-repair, ensuring that everything operates correctly before returning to normal use.

REPAIRING A SOLAR SOLENOID VALVE

1. UNDERSTANDING THE FUNCTION OF A SOLENOID VALVE

A solar solenoid valve plays a vital role in the operation of irrigation systems and other automated water management devices. By utilizing electromagnetic coils, these valves govern the flow of water and can be activated or deactivated remotely or automatically based on environmental conditions. The initial learning curve regarding how they operate helps one appreciate their significance in sustainability efforts, particularly in solar-powered applications, where efficiency is paramount.

Proper understanding of the various types of solenoid valves is essential. There are typically two configurations: normally open and normally closed. Normally closed valves stop the flow of liquid when not energized, while normally open valves allow flow until they are activated. By knowing these configurations, troubleshooting and repairs can occur more accurately, reducing downtime.

2. COMMON ISSUES WITH SOLENOID VALVES

During regular usage, several problems may arise with solar solenoid valves. Frequent issues include leaking, electric malfunctions, and binding of internal components. Leaks often occur at the seals where the valve connects to the piping, and they may be due to wear and tear or improper installation. Recognizing where these leaks manifest is crucial for effective repairs, as failure to address them adequately can result in prolonged inefficiency and water wastage.

Electrical issues can also impede the operation of solenoid valves. A malfunctioning electrical component may cause the valve to remain open or closed, disrupting the intended flow of water. In many cases, these electrical problems are tied to issues with the power source, wiring, or control systems. Diagnosing these faults requires careful inspection and often testing with a multimeter. Understanding the nature of each issue allows for targeted interventions.

3. TOOLS AND MATERIALS REQUIRED FOR REPAIR

In the journey of repairing a solar solenoid valve, having the right tools and materials at hand guarantees a smooth and successful repair process. Essential tools typically include a wrench set, screwdrivers, and possibly pliers for manipulating the various components of the valve. A multimeter is indispensable for diagnosing electrical issues, while a torque wrench ensures proper tightening without over-stressing any components.

Additionally, one must gather necessary replacement parts as needed, particularly a new solenoid if electrical failure is identified. Sealants, specifically designed for plumbing applications, are also vital for addressing leaks and securing fittings. With these tools at your disposal, you are equipped to tackle most issues effectively.

4. PREPARING FOR REPAIR WORK

Preparation is crucial before undertaking any physical repair work on a solar solenoid valve. Safety precautions should always be considered first. Turn off the water supply and ensure that the power source is disconnected to prevent electric shock or water damage. Completing a risk assessment can help identify potential issues before they arise, setting the stage for a safe working environment.

Following safety measures, a detailed plan should be outlined. This includes deciding on the necessary steps to take based on the diagnosed issues, and it may be helpful to document the existing setup for reference. Gathering all the tools and materials in one place simplifies the workflow and minimizes delays during the repair.

5. DISASSEMBLING THE SOLENOID VALVE

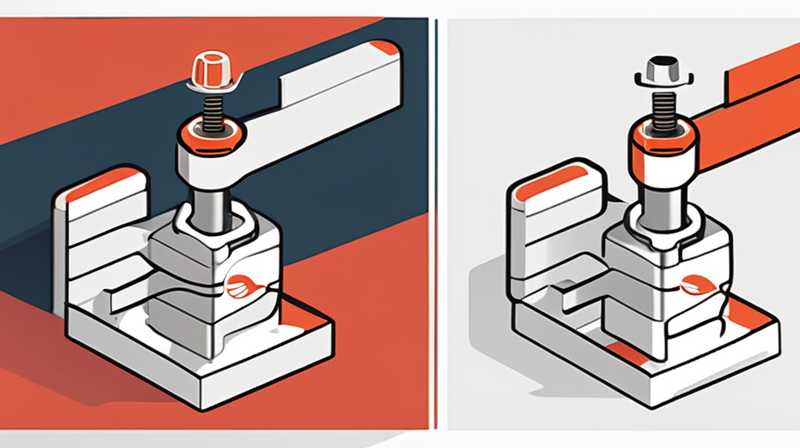

Once preparations are complete, the next step involves carefully disassembling the solar solenoid valve. Begin by detaching any tubing or fittings connected to the valve. Use a wrench to loosen fittings, taking care to avoid stripping any threads. As each component is removed, it’s advisable to keep them organized and label them if necessary to ensure an efficient reassembly.

Pay attention to the internal components of the solenoid valve once it has been disassembled. Inspect the solenoid for signs of wear or damage, particularly the coil and plunger. If there’s any obvious damage, a replacement might be necessary. Carefully document the condition of parts to inform your repair strategy.

6. REPLACING OR REPAIRING COMPONENTS

Depending on your findings during disassembly, you must decide whether to replace or repair components. If the solenoid coil appears damaged or has broken wiring, it’s often more reliable to replace it completely rather than attempting a repair. Acquiring a compatible solenoid is crucial, as specifications vary among models.

In cases where minor issues are present, such as a sticking plunger or debris in the valve, cleaning and lubrication can often restore functionality. Use a soft brush or cloth to remove debris, followed by an appropriate lubricant to ensure smooth operation. This step can extend the life of the solenoid valve, but it is not a substitute for replacing worn out parts.

7. REASSEMBLING THE SOLENOID VALVE

Upon completing repairs or part replacements, it’s time to reassemble the solar solenoid valve. Begin with the internal components, ensuring that each part is secured in the correct order. This is where previous documentation proves beneficial; following the original configuration reduces the likelihood of errors.

Carefully reattach any tubing or fittings on the exterior of the valve, ensuring to tighten connections without over-torquing them, as this can lead to further leaks or breakage. After everything is secure, conduct a thorough inspection to ensure everything is in place before reintroducing power and water to the valve.

8. TESTING AND VALVE OPERATION

Testing the solar solenoid valve is the final phase of the repair process. Upon reactivation, monitor the valve’s operation carefully to identify any lingering issues. First, turn on the water supply slowly to avoid surges, and observe for leaks around the connections. The solenoid should engage and disengage according to your control system inputs; any anomalies at this stage may indicate further underlying issues that require resolution.

Additionally, testing the response of the solenoid to electrical signals is crucial. Use a multimeter to measure the voltage across the solenoid terminals during operation. If readings are abnormal, additional investigation into the electrical system might be warranted. Properly functioning valves are integral to effective irrigation systems; ensuring they operate correctly post-repair enhances overall system efficiency.

FREQUENTLY ASKED QUESTIONS

HOW CAN I DETERMINE IF MY SOLENOID VALVE IS BROKEN?

Determining the state of a solenoid valve can involve a series of diagnostic steps. Frequently, one will observe that the valve does not open or close when it should, indicating a possible malfunction. Begin with a visual inspection, noting any obvious signs of wear, leaks, or damage. If external issues are not detected, consider utilizing a multimeter for electrical assessment.

Measuring voltage at the solenoid terminals during operation can reveal if it is receiving power. A malfunctioning solenoid will likely show improper voltage readings compared to the specified requirement. Testing the coil’s resistance can also indicate failure; low or infinite resistance often reflects internal damage. Thorough evaluation combining visual checks and electrical testing leads to a comprehensive understanding of the valve’s operational status.

WHAT ARE SOME TIPS FOR MAINTAINING SOLENOID VALVES?

Regular maintenance significantly prolongs the life of solenoid valves and ensures they operate reliably. One primary practice is to inspect the valve periodically, looking for signs of wear or corrosion, especially in outdoor settings where weathering may affect components. Cleaning external surfaces can also prevent debris buildup that may impede function.

Another essential maintenance tip involves ensuring the electrical connections are secure and free from corrosion. Reviewing the control systems for proper function and any signs of wear will enhance overall efficiency. Additionally, using lubricants specifically designed for plumbing applications can aid internal components in moving freely. Developing a routine maintenance schedule will help catch potential issues early, reducing the need for repairs down the line.

HOW DO I CHOOSE THE RIGHT SOLENOID VALVE FOR MY SYSTEM?

Selecting the appropriate solenoid valve is crucial for the efficiency of any watering or irrigation system. Several key factors should be considered, including flow rate, pressure rating, and fluid compatibility. Identifying the required flow rate helps narrow down options, ensuring that the valve can handle the volume of water necessary for your application.

Pressure ratings are equally important, as exceeding the limits of a valve can lead to premature failure. Consider the environment in which the valve will operate; choosing materials that can withstand the particular chemicals or temperatures of your system is necessary to avoid early degradation. Consulting documentation or marketing materials can aid in making informed decisions, ensuring the selected valve meets operational requirements satisfactorily.

Repairing a solar solenoid valve requires a thoughtful, systematic approach to ensure efficiency and functionality. By identifying issues, gathering appropriate tools, preparing adequately, performing repairs, and testing the system post-operation, one can maintain effective water management systems. Thorough inspections, regular maintenance, and informed replacements contribute to a successful repair process. Understanding the intricacies of solenoid valves, their functions, and common issues can help homeowners and professionals alike optimize their systems. Engaging in a proactive maintenance schedule facilitates both short-term performance and long-term reliability. Ultimately, taking the time to properly address repair needs upholds sustainability goals while conserving water resources, underscoring the importance of diligence in managing solar-powered irrigation systems.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-repair-a-solar-solenoid-valve/