To effectively repair a solar-powered Buddhist scripture broadcasting machine, you need to follow several essential steps. 1. Assess the machine for any visible damage or component issues, 2. Check the solar panels for proper functionality and connections, 3. Inspect the batteries for charge levels and integrity, 4. Examine the internal electronics for any signs of failure or wear. For a more detailed approach, proper documentation of the machine’s components and understanding each part’s role will greatly aid in troubleshooting.

1. OVERVIEW OF THE MACHINE

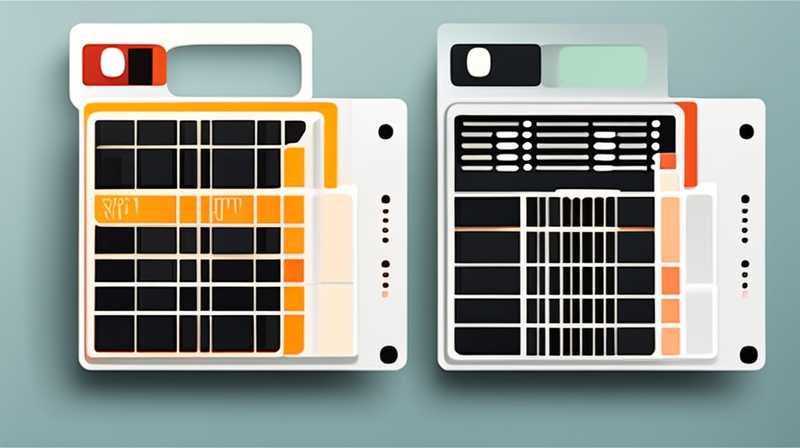

Recognizing the importance of understanding the device is crucial when it comes to maintenance and repair. A solar-powered Buddhist scripture broadcasting machine typically consists of several integral components working synergistically to operate effectively. Solar panels, batteries, internal circuitry, audio output systems, and user control interfaces form the backbone of this system. Each element must function harmoniously to ensure that scriptures can be broadcasted clearly and reliably to the intended audience.

Solar panels convert sunlight into electrical energy, which is then used to charge the batteries. These batteries provide the energy required to power the broadcasting system at any time, regardless of sunlight availability. The internal circuits manage the distribution of power to various components, ensuring that users can broadcast scripture effectively. A deeper understanding of these functions will aid significantly in pinpointing issues that may arise during operations.

2. COMMON ISSUES FACED

The longevity and efficacy of solar-powered devices depend on regular maintenance; however, certain problems may arise over time that necessitate intervention. Common issues include inadequate charging of batteries, malfunctioning solar panels, and internal circuit failures. Each issue presents unique challenges and requires a methodical approach to diagnosis and repair.

Inadequate battery charging can be linked to faulty solar panels or wiring issues. In such cases, a thorough inspection of the solar panel connections is vital to determine whether they are producing the expected voltage and current. If the solar panels are functioning properly, one must assess the condition of the batteries themselves, as they may have deteriorated and thus unable to hold a charge efficiently.

Similarly, malfunctioning solar panels may arise from physical damage, dirt accumulation, or wear from exposure to harsh weather conditions. An inspection involves checking for cracks, broken connections, and ensuring the panels are clean and positioned correctly for optimal sunlight exposure. If the panels are dirty, cleaning them using non-abrasive materials can significantly improve efficiency.

3. INITIAL ASSESSMENT OF THE MACHINE

Before delving into repairs, a comprehensive evaluation will save time and resources. Start by disconnecting the power supply and inspecting all external connections. Visual checks may uncover loose wires, corrosion, or signs of wear. Attention to detail often reveals critical factors influencing the machine’s performance.

Next, investigate the attachment of solar panels to the machine. Ensure they are securely fastened and strategically angled to maximize sunlight exposure. An effective alignment significantly impacts how power is generated and subsequently utilized. Understanding these fundamental aspects sets the stage for more in-depth troubleshooting moving forward.

4. TECHNICAL INSPECTION OF COMPONENTS

Following the initial evaluation, proceed with a more technical examination of all components. Utilizing specialized tools such as multimeters and oscilloscopes will facilitate a more thorough understanding of component functionality. By measuring voltage and current production levels at various points, one can assess if components are functioning within their operational specifications.

When scrutinizing the batteries, take care to test both voltage levels and their ability to hold charge. A battery that shows low voltage may still seem operational but can fail under load. Load tests should be performed to ensure that batteries maintain adequate performance, thus preventing broadcasting failures during critical periods.

5. REPAIRS AND REPLACEMENTS

Should any components fail during inspection, timely action is required. Replacement of broken solar panels, batteries, or circuit boards can restore functionality. Prices for replacement parts may vary, and it’s useful to consult the manufacturer’s specifications to avoid compatibility issues.

When replacing components, ensure that each new part aligns with the machine’s original specifications. Proper installation practices, including secure connections and proper alignment of solar panels, will enhance the device’s reliability. Attention to detail during this phase cannot be overstated, as improper installations can lead to repeated failures.

6. PREVENTIVE MAINTENANCE STRATEGIES

Adopting a preventive maintenance strategy can significantly prolong the lifespan of the solar-powered broadcasting machine. Establish a regular schedule for cleaning the solar panels and examining internal components. Routine checks are crucial to catch potential issues before they escalate into significant repair needs.

Monitoring weather conditions in relation to how they might affect device performance can also be beneficial. For instance, extreme temperatures or prolonged cloud cover can impact battery performance. Being proactive allows for adjustments like relocating the solar panels or installing enhancements to provide additional energy support when necessary.

7. COMMUNITY ENGAGEMENT AND INSTRUCTION

A significant aspect of managing a solar-powered Buddhist scripture broadcasting machine includes educating community members on proper usage and reporting malfunctions promptly. Workshops or informational sessions can bridge the gap between users and the technical aspects of the equipment. Ensuring that everyone involved understands the operational limits can mitigate the occurrence of misunderstandings that might lead to undue wear or damage.

Encouragement of a communal approach to maintenance creates a sense of ownership over the equipment. Additionally, sharing insights on best practices can foster an environment where everyone is vigilant and proactive regarding the machine’s upkeep.

8. UPGRADING THE SYSTEM

As technology advances, it may become advantageous to consider upgrades for improved performance. Integrating modern technologies like advanced battery systems or state-of-the-art charge controllers can make a significant difference. Researching compatible upgrades allows the existing system to benefit from enhanced energy efficiency and output.

When exploring new technologies, consult with experts and compare products based on user experiences and system compatibility. Engaging in discussions with technology providers may reveal options that could remarkably enhance the machine’s capabilities. Adopting modern solutions to traditional issues is part of progressive maintenance.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE AVERAGE LIFESPAN OF SOLAR PANELS USED IN THESE MACHINES?

Solar panels typically have an operational lifespan ranging from 25 to 30 years, depending on quality, maintenance, and environmental conditions. Several factors can influence this longevity, including exposure to harsh weather, dirt accumulation, and manufacturing quality. Regular checks and maintenance can prolong their effectiveness, ensuring they generate the necessary power for the broadcasting machine continuously.

Frequent cleaning reduces damage caused by dirt and grime, while regular inspections help in identifying any physical damage early. Upgrading to high-performing solar panels may also be an option if longevity is a concern. It is essential to monitor the panel’s output regularly and replace them as needed to maintain consistent performance.

HOW CAN I KNOW IF MY BATTERY NEEDS REPLACEMENT?

When assessing whether a battery requires replacement, there are typical signs to observe. Decreased performance, such as reduced broadcasting time or inability to hold a charge, typically indicates that it’s time for a replacement. Testing the battery with a multimeter can reveal voltage issues and provide insights into whether the battery is functioning within expected parameters.

Additionally, physical inspection may highlight external damage or corrosion, suggesting a need for replacement. Regular small-load tests can determine if they still perform effectively or if deterioration is evident. Keeping records of each test will also help in making informed decisions regarding battery longevity and replacement schedules.

WHAT KIND OF CLEANING SOLUTIONS ARE SAFE FOR SOLAR PANELS?

Cleaning solutions should be treated with care when addressing solar panels. The best approach includes using mild soap mixed with warm water and applying it with a soft cloth or sponge. It is crucial to avoid abrasive materials and harsh chemicals which can scratch or damage the panel surfaces.

Many users opt for distilled water, which leaves no residue, combined with gentle, circular motions for cleaning. Performing this activity during cooler parts of the day or opting for overcast days can prevent water from evaporating too quickly, which could leave behind marks. This simple yet effective cleaning routine will help maintain panel performance.

Repairing a solar-powered Buddhist scripture broadcasting machine involves a multi-faceted approach that emphasizes assessment, inspection, maintenance, and community engagement. Recognizing the various components’ roles lays the groundwork for effective problem identification. Investing time in understanding each part ensures that repairs and upgrades are implemented precisely. This proactive mindset is reinforced by systematic preventive maintenance that helps in sustaining machine efficacy. Furthermore, informing community members about the significance of maintaining these machines fosters a culture of care and responsibility. By keeping abreast of technological developments, one can ensure that the machine remains functional and efficient through its gained upgrades. Therefore, a harmonious blend of technical understanding and community involvement remains paramount to preserving this vital broadcasting equipment for years to come.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-repair-a-solar-powered-buddhist-scripture-broadcasting-machine/