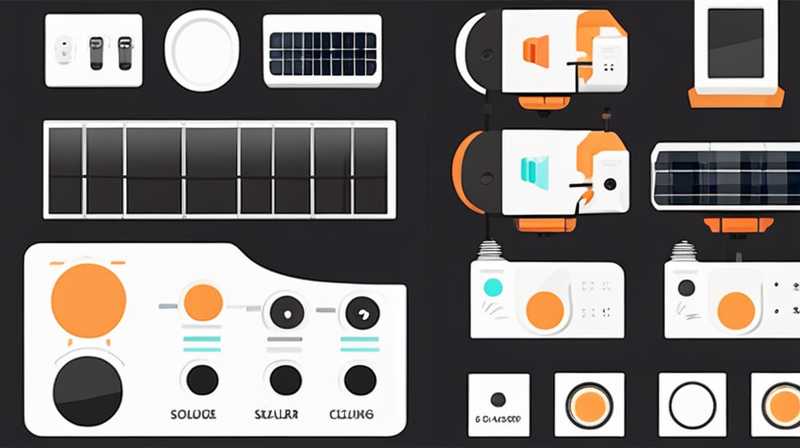

How to Repair a Solar Light Control Panel

Repairing a solar light control panel involves a few essential steps. 1. Diagnosis is crucial; assessing potential failures can determine if the issue is with the panel, battery, or wiring. Common problems include faulty connections, damaged solar cells, or malfunctioning internal circuits. 2. Tools and safety measures are necessary to effectively undertake repairs. Using insulated tools and ensuring the solar light is de-energized can prevent electric shocks and further damage. 3. Replacement parts may be required depending on the diagnosis. Identifying and sourcing compatible components is essential for restoring functionality. 4. Testing after repairs is vital; ensuring the system operates under sunlight confirms that repairs were successful. Each step must be executed with precision to ensure the longevity and effectiveness of the solar light system.

1. UNDERSTANDING SOLAR LIGHT CONTROL PANELS

The functionality of solar lights heavily relies upon their control panels. These panels are responsible for managing the operations of the solar lighting system, which typically includes monitoring battery levels, controlling light intensity, and regulating on-off cycles based on ambient light. The control panels consist of various components, including photovoltaic cells and integrated circuits, that work together to convert sunlight into usable energy.

Furthermore, the control panel plays a pivotal role in extending the life of solar lights. This is achieved through effective management of battery charging and discharging cycles. When sunlight is available, the system optimizes energy collection and storage, but during nighttime, it carefully regulates power usage to ensure maximal output from the stored energy. Hence, understanding these underlying functions is fundamental when attempting to repair or troubleshoot a malfunctioning control panel.

2. COMMON ISSUES WITH SOLAR LIGHT CONTROL PANELS

When dealing with malfunctions in solar light control panels, understanding the most common issues can significantly streamline the repair process. Faulty connections, for instance, often arise due to environmental factors such as moisture or corrosion. This can lead to intermittent power supply or complete failure to function. It is vital to regularly inspect the connections for signs of wear or corrosion, particularly in outdoor installations.

Damaged solar cells represent another prevalent issue. The photovoltaic cells can suffer from physical damage or degradation over time, which diminishes their capacity to convert sunlight into electricity. Continuous exposure to harsh weather conditions may lead to cracks or discoloration of the cells. To ensure operational longevity, regular inspections of the solar panel’s surface are necessary to identify any irregularities that may require attention or replacement.

3. TOOLS REQUIRED FOR REPAIRING SOLAR LIGHT CONTROL PANELS

When embarking on the repair of a solar light control panel, it is essential to have the appropriate tools at hand. Insulated tools are paramount in preventing electrical shocks, particularly when working on live circuits. Common tools include insulated screwdrivers, pliers, and wire strippers. Having a multimeter is also invaluable for testing voltage levels and continuity within the control panel.

In addition, safety equipment such as gloves and goggles should be worn to protect against potential hazards. Ensuring a well-lit work area can facilitate effective troubleshooting and repairs. Moreover, having a toolkit specifically designed for electronic repairs can enhance efficiency, as it typically includes specialized components that can aid in replacing damaged parts or securing loose connections. A well-prepared technician is more likely to navigate the repair process successfully.

4. SAFETY MEASURES DURING REPAIR

Safety should never be compromised when attempting repairs on solar light control panels. Before commencing work, it is essential to disable the solar light system entirely to prevent any accidental electrical shocks. Discharge the capacitor units if applicable, as they can retain electrical current even when the system is powered off. Ensuring that all tools used are insulated reduces the risk of electrical accidents during repair.

Additionally, working in a dry environment is crucial, as moisture can lead to short circuits or further damage to components. If repairs are taking place in adverse weather, delaying tasks until a more favorable condition can prevent potential hazards. Following fundamental safety protocols not only protects the technician but also ensures that the solar light system is handled appropriately, mitigating the risk of permanent damage during repairs.

5. REPLACEMENT PARTS AND SOURCING

Identifying and sourcing the correct replacement parts plays a significant role in the repair of solar light control panels. Once a diagnosis has been made, the next step is to explore options for replacement components. These can include batteries, solar cells, and integrated circuit boards, depending on the identified issues.

To find compatible parts, it is advisable to refer to the original manufacturer’s recommendations and specifications. Many retailers offer a variety of components designed for specific models. There are also numerous online platforms and marketplaces where users can find compatible parts. Ensuring that replacement components match the original specifications is vital for maintaining the efficiency and longevity of the solar light system. Moreover, if high-quality replacement parts are used, the overall performance can significantly improve compared to using substandard components.

6. TESTING THE REPAIRED SOLAR LIGHT CONTROL PANEL

After completing the repairs, it is paramount to systematically test the solar light control panel to confirm proper functionality. Begin by reassembling the unit carefully, ensuring that all connections are secure and that no tools or debris are left inside the enclosure. Following assembly, reintegrate the control panel into the system, ensuring everything aligns accordingly.

Testing begins with the initial charging of the solar panel under sunlight. Observing the energy transfer and monitoring battery levels will indicate whether the repairs were successful. After sufficient sunlight exposure, check the operational aspects during nighttime hours. This includes confirming that the light activates at dusk and operates as expected throughout the night. Any inconsistencies found during testing should prompt further diagnostics to identify unresolved issues.

FAQ

WHAT ARE THE SIGNS THAT A SOLAR LIGHT CONTROL PANEL IS MALFUNCTIONING?

Several indicators suggest that a solar light control panel may be malfunctioning. Common signs include the light not turning on at night, dim lighting, or flickering, which could indicate insufficient power. Additionally, if the system fails to recharge during the day despite adequate sunlight, the control panel may have an internal issue. Testing the connections and voltage levels using a multimeter can help pinpoint faults. Corrosion at the connections can impede power flow, while visibly damaged solar cells can also halt functionality. Ultimately, regular maintenance and inspections can prevent serious malfunctions, ensuring reliability.

HOW OFTEN SHOULD SOLAR LIGHT CONTROL PANELS BE INSPECTED?

Inspecting solar light control panels is essential for long-term functionality. It’s recommended to conduct a thorough inspection at least twice a year, ideally before and after the summer season when exposure is highest. This will address any wear caused by environmental elements. During inspections, technicians should check for corrosion, loose connections, and any signs of physical damage to the solar cells. Cleaning the surface of the solar panels frequently, particularly in dusty or sooty areas, can significantly improve performance. Regular checks can prevent minor problems from escalating into more significant issues, thus extending the lifespan of the solar lighting system.

CAN I REPAIR MY SOLAR LIGHT CONTROL PANEL MYSELF, OR SHOULD I HIRE A PROFESSIONAL?

The decision to repair a solar light control panel oneself or hire a professional depends on several factors, including technical expertise, tool availability, and personal comfort level. For those experienced with electronics and possessing the necessary tools, self-repair can be feasible and cost-effective. However, for individuals lacking experience or technical skills, enlisting a professional is advisable to avoid further damaging the system or compromising safety. Professionals not only bring expertise but also have access to specialized tools and replacement parts that can expedite the repair process. Weighing these considerations carefully will lead to the best decision based on the unique circumstances.

Repairing a solar light control panel requires a systematic approach, emphasizing diagnosis, safety, and testing. A thorough understanding of common issues related to control panels is vital to address problems effectively. By equipping oneself with appropriate tools and components, along with adhering to safety measures, individuals can undertake repairs with confidence. The frequency of inspections determines the long-term functionality and reliability of solar systems, showcasing preventative measures as paramount. Engaging in self-repair is viable for those with adequate knowledge and tools, while enlisting professional help ensures expedient restoration for those less familiar with electronic systems. Each step in the repair process is critical, and when executed with precision, can extend the lifespan of solar lighting systems significantly. Ultimately, regular maintenance and attentiveness ensure that solar lights operate at full efficiency, providing sustainable, eco-friendly illumination.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-repair-a-solar-light-control-panel/