To repair a broken solar triple valve, begin by identifying the source of the issue, 1. assess valve condition, 2. gather necessary tools, 3. perform disassembly, 4. inspect components. The first step involves examining the valve for any visible signs of damage or wear such as cracks, leaks, or corrosion. This not only helps in determining the extent of the problem but also in figuring out whether a complete replacement or specific repairs are needed. It is vital to ensure that the system is depressurized and drained before working on the valve to prevent any accidents or further damage. Once the assessment is complete, the appropriate tools must be collected, including wrenches, screwdrivers, and sealants, to ensure a smooth repair process. Following this, care must be taken while disassembling the valve. Each part should be labeled to avoid confusion during reassembly. The inspection of components is crucial—replace any damaged elements identified during the initial assessment, and ensure that seals and O-rings are also in good condition, as these parts are essential for maintaining a leak-free operation.

1. UNDERSTANDING THE FUNCTION OF A SOLAR TRIPLE VALVE

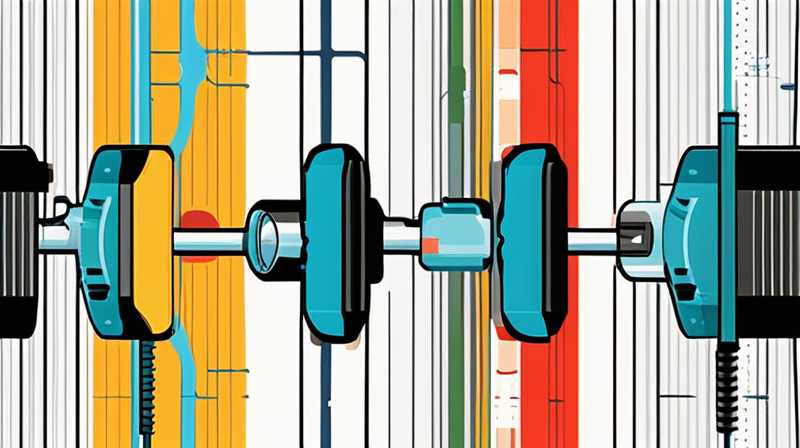

The solar triple valve plays a pivotal role in solar heating systems, operating as a critical component in the transfer of heat between the solar collector and the storage tank. It helps in regulating the flow of heat transfer fluid based on the temperature differentials. Primarily, these valves are designed to divert the fluid flow to ensure that energy is not wasted and that the heat generated is efficiently utilized.

The correct functioning of a solar triple valve can significantly impact the efficiency of the entire solar heating system. If the valve fails, it could potentially lead to overheating or underheating issues, resulting in rising utility costs and diminishing system reliability. Advanced understanding of how these valves operate will enable one to take the necessary steps when repairs are required, saving time and money while ensuring the continuity of heating efficiency.

2. IDENTIFYING COMMON ISSUES

Various problems can arise with solar triple valves, typically stemming from wear due to thermal expansion, mechanical stress, or even debris clogging the system. Recognizing these issues is essential for successful repairs. One common issue is leakage, usually caused by a failing seal or O-ring within the valve. A small leak can lead to a significant loss of heat transfer fluid, and if not addressed, can lead to more considerable operational problems.

Another issue is failure to divert flow correctly, often resulting from obstruction or mechanical failure inside the valve. Clogs can impede proper functionality, causing inadequate energy transfer from the solar collectors to the hot water tank. Addressing these issues in a timely manner is crucial to maintaining system effectiveness, thereby prolonging the life of the entire heating setup and preventing costly replacements.

3. GATHERING NECESSARY TOOLS AND MATERIALS

Before initiating any repair procedure on a solar triple valve, acquiring the right tools and materials is imperative. One should have at hand wrenches for loosening the connections, screwdrivers for disassembly, and appropriate replacement parts such as seals, O-rings, or even an entirely new valve if necessary. Additionally, it is advisable to have cleaning supplies available for removing any debris that may have accumulated within the system.

The materials used must be compatible with the fluid in the system. For instance, if using synthetic oils, ensure that seals and O-rings are appropriately rated to prevent degradation. Having everything prepared beforehand can streamline the repair process, alleviate delays, and enhance efficiency. It also reduces the risk of damage from using incorrect materials, which may lead to further system failures down the line.

4. DISASSEMBLING THE VALVE

Disassembly of the valve should only commence once all preparations are complete. Take the necessary steps to ensure safety by depressurizing the system and draining the fluid. Depending on the model, it may require loosening bolts or using specialized tools to remove the valve from the piping. Ensure that all connections are marked clearly during this process to prevent confusion upon reinstallation.

Once the valve is removed, take care to clean each component thoroughly. This should include removing any old sealants and checking for the presence of debris. Proper cleaning is essential as it ensures that all surfaces are ready for inspection or replacement, which greatly assists in achieving proper sealing when reassembling, minimizing potential for future leaks.

5. INSPECTING COMPONENTS

Inspection of each part within the valve is a vital part of the repair process. Focus on identifying any cracks, corrosion, or wear that may affect functionality. Commonly, seals and O-rings are prone to damage and should be replaced if any signs of deterioration are observed. It’s imperative to take a meticulous approach, scrutinizing every detail to avoid missing potential failure points that could compromise the system later.

If components appear beyond repair, replacement parts should match the specifications of the original valve. When replacing components, ensure they are compatible with temperature and pressure specifications to maintain the integrity and efficiency of the system. Only then can one proceed with the reassembly of the valve, ensuring each part is securely fastened according to manufacturer guidelines.

6. REASSEMBLING THE VALVE

Upon completion of the inspection and necessary replacements, the next phase involves reassembling the solar triple valve. Begin by placing the new or repaired components in their designated positions, ensuring that all surfaces are clean and free from debris. Following this, apply any required sealants to ensure a tight seal during operation.

Care is required to avoid over-tightening the connections, as this could lead to distortion of fittings or threads, which may cause leaks. Each connection should be checked to confirm that it is both secure and appropriate. After assembly, it is imperative to conduct a thorough inspection to ensure all components are intact, and that no tools or materials are inadvertently left within the system.

7. REINTEGRATING THE VALVE INTO THE SYSTEM

The reintegration of the repaired valve back into the solar heating system requires an understanding of the original layout. Position the valve back into the piping with attention to ensure correct orientation and flow direction as indicated in the original installation. This step is crucial as incorrect positioning can lead to malfunction of the entire heating setup, jeopardizing system performance and efficiency.

Before re-pressurizing the system, double-check all connections for any signs of visible leakage. Once re-mounted, gradually reintroduce fluid into the system, monitoring pressure levels closely. It is also wise to bleed the system if necessary to remove any air pockets that may have formed during the repair process. Proper reintegration ensures that the repaired valve functions as intended alongside the entire solar heating infrastructure.

8. TESTING FOR FUNCTIONALITY

After successfully reintegrating the valve to the system, rigorous testing must follow. Observing the system in operation is essential to ensure that the valve is performing its intended function without leaks or faults. Check for proper flow rates and temperature readings to confirm that the valve is efficiently directing the heat transfer fluid correctly between the solar collector and the storage tank.

Continuous monitoring during the testing phase is crucial, as it allows one to quickly identify any discrepancies. If abnormalities persist, it may necessitate further inspection or adjustments. Testing not only validates the success of the repairs but also provides reassurance that the entire solar heating system is operating at optimal performance levels post-repair.

9. MAINTAINING VALVE PERFORMANCE

Post-repair, focusing on maintenance can help prolong the life of a solar triple valve. Regular checks of the system are recommended to catch any potential issues early, avoiding larger repair projects down the line. This can include monitoring for any visual signs of leaks, ensuring fluid levels are maintained, and temperatures are consistent across the system.

Additionally, keeping the valve area clean from dust, debris, and other unwanted materials can minimize the risk of clogs developing in the future. Implementing these proactive measures not only enhances performance but also contributes to overall system longevity, maximizing the return on investment for the solar heating solution.

10. COMMON QUESTIONS

HOW CAN I DETERMINE IF THE VALVE IS DEFECTIVE?

Identifying a defective valve requires a thorough examination of its physical state, inspecting for cracks or leaks. Temperature variations and irregular fluid flow can also indicate operational issues. Regular maintenance checks can help detect underlying problems early on.

WHAT ARE THE SIGNS OF A LEAKING SOLAR TRIPLE VALVE?

Visual signs include pooled fluid around the valve, unusual drops in fluid levels in the system, and noticeable fluctuations in heating performance. If any of these signs are present, immediate inspection and repair are necessary to avoid system failure.

IS IT BETTER TO REPAIR OR REPLACE A BROKEN VALVE?

The choice to repair or replace depends on the extent of the damage and the valve’s age. Minor issues might be easily repaired, while extensive damage may warrant replacement to ensure reliability. Consulting a professional can provide guidance tailored to specific circumstances.

In essence, repairing a broken solar triple valve entails a structured approach that prioritizes safety, meticulous preparation, and thorough understanding of the valve’s function. By following a detailed process, one not only restores the valve to proper working order but also preserves the efficient performance of the entire solar heating system. Extensive examination of the valve components, adequate maintenance, and establishment of monitoring routines are vital in averting future issues. Engaging in these practices not only contributes to sustainability by ensuring the system operates as intended, maximizing energy efficiency within the solar heating framework. Overall, approaching repairs with diligence and expertise fosters an enduring investment that benefits both performance and reliability, solidifying the functionality of solar energy systems for years to come.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-repair-a-broken-solar-triple-valve/