To repair a broken solar self-priming pump, one should follow several essential steps. 1. Identify the problem accurately, 2. Gather necessary tools and replacement parts, 3. Disassemble the pump carefully, 4. Perform required repairs or replacements, 5. Reassemble the pump, and **6. Conduct testing to ensure functionality.

Proper diagnosis is critical, as it allows the technician to target the specific issue preventing the pump from performing as intended. Check for common causes such as clogged filters or damaged impellers, as these may necessitate particular attention. Additionally, replacement parts should be compatible with the pump model to ensure optimal performance.

1. UNDERSTANDING SOLAR SELF-PRIMING PUMPS

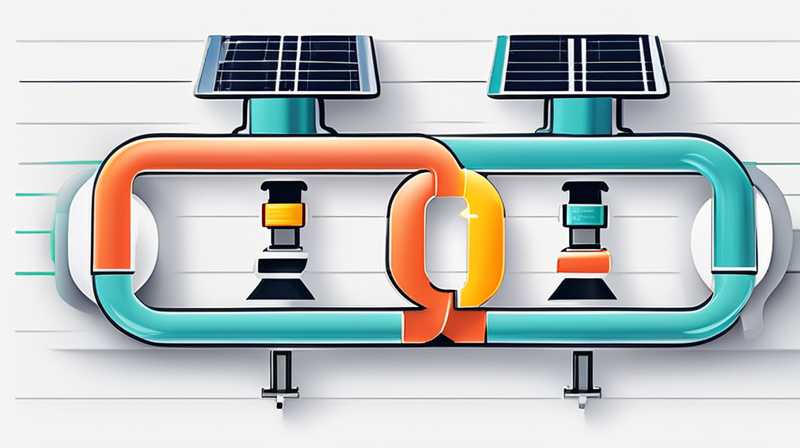

Solar self-priming pumps serve as a crucial component in various applications, particularly in areas lacking a reliable power supply. These specialized devices leverage solar energy to facilitate fluid movement, making them ecologically friendly and energy-efficient. Understanding the intricacies of their operational design helps one appreciate their vulnerabilities and the reasons they may fail.

At the core of these pumps lies the importance of the self-priming feature, enabling them to draw water without external aids. This feature is advantageous in scenarios where constant water supply is essential, such as irrigation, water features, or livestock watering systems.

2. COMMON ISSUES AND DIAGNOSIS

Diagnosing problems with solar self-priming pumps is often straightforward if one is familiar with common issues. Failures might stem from electrical malfunctions, mechanical breakdowns, or environmental factors. A thorough assessment involves examining both the electrical components, such as the solar panel and its connections, and the mechanical aspects, including the pump casing and impeller.

In many instances, still water in the pump can lead to undesired wear and tear. This problem can be exacerbated by sediment and other debris that accumulates over time. Therefore, conducting periodic maintenance can preemptively address issues that could otherwise culminate in a complete pump breakdown.

3. GATHERING TOOLS AND PARTS

Before initiating repairs, one must ensure they possess the necessary tools and replacement parts. Various tools may be essential, ranging from wrenches and screwdrivers to specialized kits specifically designed for pump repair. Having the right tools on hand streamlines the repair process and minimizes the risk of further complications.

Additionally, identifying and sourcing replacement parts is crucial. Components like gaskets, seals, and impellers require careful consideration to avoid compatibility issues. One should consult the pump’s manual or specifications to ascertain the correct part numbers and dimensions.

4. DISASSEMBLING THE PUMP

Upon gathering necessary tools and parts, the disassembly of the pump requires attention to detail. Start by disconnecting the pump from its power source and draining any residual fluid. This precaution ensures safety and prevents accidents during the repair process.

When disassembling, take photographs or notes of the setup. Documenting each step aids in reassembly and ensures no essential component is overlooked or misplaced. Carefully removing screws and components while avoiding unnecessary force will prevent damage to delicate parts.

5. PERFORMING REPAIRS OR REPLACEMENTS

With the pump disassembled, repair efforts can commence. Inspect each component meticulously for wear, damage, or blockage. This critical evaluation helps determine which parts necessitate replacement and which can be cleaned and reused safely.

If an impeller is damaged or has lost its function, replacing it with a new, compatible component is essential for restoring efficiency. Cleaning clogged filters and ensuring that connections are airtight can significantly enhance the pump’s functionality post-repair.

6. REASSEMBLING THE PUMP

Once repairs or replacements are complete, the next stage involves reassembly. Follow the earlier documented steps to ensure each component returns to its rightful place. Take care to reinstall gaskets and seals correctly, as improper placement can lead to leaks down the line.

Ensure all screws and connections are tightened adequately but avoid over-tightening, which could lead to fractures or misalignments. After reassembly, double-check each component and connection to affirm uniformity and effectiveness.

7. TESTING THE REPAIRED PUMP

Post-repair testing verifies functionality and ensures that the pump operates smoothly. Reconnect the pump to its power source and monitor its performance closely. Look for any leaks or unusual noises that could indicate improper assembly or faulty components.

During testing, note the pump’s response to various demands, such as pressure fluctuations and flow consistency. Adjustments may be necessary to calibrate the pump for optimum performance after repairs are complete.

FREQUENTLY ASKED QUESTIONS

HOW OFTEN SHOULD I PERFORM MAINTENANCE ON MY SOLAR SELF-PRIMING PUMP?

Regular maintenance is essential for the longevity of a solar self-priming pump. Experts recommend checking your pump at least once every six months. This regular check-up should include inspecting for any visible wear and tear, evaluating the connections, and cleaning any clogged filters. Proper maintenance can significantly mitigate the risk of unexpected breakdowns, primarily when pumps are actively used in settings such as agriculture, landscaping, and other water-dependent applications.

In addition to scheduled maintenance checks, it is wise to monitor the pump’s performance during periods of heavy use, as environmental factors may lead to unforeseen complications. Continuously monitoring the surrounding area can reveal signs of sediment buildup or mechanical strain that may affect the pump’s efficiency. Keeping a maintenance log allows pump owners to anticipate issues more accurately and perform necessary repairs promptly.

WHAT ARE THE MAIN SIGNS OF A MALFUNCTIONING SOLAR SELF-PRIMING PUMP?

Recognizing the signs that indicate a malfunctioning solar self-priming pump is vital in ensuring timely repairs and maintenance. Common indicators include inconsistent water flow, unusual noises, or a complete lack of function. Pump users should remain vigilant in observing their systems, as early detection of issues can prevent more significant repairs or replacements.

Another crucial sign is inadequate priming leading to poor suction. This issue might suggest either blockages in the system or a defective impeller. It can be beneficial to routinely check the pump’s pressure output, as significant drops may indicate underlying problems. A malfunctioning pump can often be corrected through careful diagnosis and appropriate repairs, but neglecting signs of malfunction may lead to further damages and operational difficulties.

CAN I REPAIR A SOLAR SELF-PRIMING PUMP MYSELF, OR SHOULD I HIRE A PROFESSIONAL?

While many individuals possess the skills to undertake their repairs on a solar self-priming pump, one must first assess their capabilities before embarking on a repair endeavor. Fixed guidelines can equip DIY enthusiasts with the knowledge necessary for successful repairs, while certain scenarios may demand specialized expertise or tools only a professional can provide.

If the problem involves complicated electrical components or if the owner is unsure about identifying specific mechanical issues, consulting a professional is advisable. Doing so can streamline repairs and ensure optimal functionality, potentially saving time and costs while providing peace of mind. On the other hand, if one feels confident in their abilities, with adequate documentation and guidance, self-repair can be a rewarding and cost-effective option.

In summary, repairing a broken solar self-priming pump involves several stages that require precise attention. Initiating the process by diagnosing the problem is imperative before gathering tools and parts. The disassembly must be executed carefully, enabling thorough evaluations and targeted repairs or replacements. Upon reassembly, rigorous testing is natural to ensure that the pump operates efficiently. Understanding specific malfunctions, how to maintain the pump, and whether to consult professionals are also critical factors for operators. Timely repairs and consistent maintenance contribute significantly to the longevity and efficiency of solar self-priming pumps, ultimately leading to a reliable water supply.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-repair-a-broken-solar-self-priming-pump/