To repair a broken solar photovoltaic panel, it’s essential to understand the specific type of damage sustained and follow a systematic approach. 1. Identify the damage, such as cracks or delamination. 2. Gather necessary tools and materials, including a multimeter, adhesive, and protective equipment. 3. Clean the affected area to ensure proper adhesion. 4. Apply the appropriate repair techniques, which may involve replacing glass or re-sealing the panel. 5. Test the panel to confirm functionality. Proper care and attention can restore its efficiency effectively.

1. UNDERSTANDING SOLAR PHOTOVOLTAIC PANELS

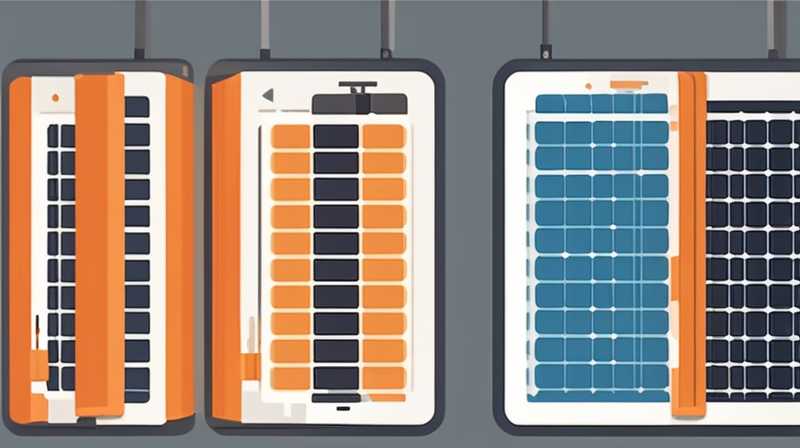

Solar photovoltaic panels play a vital role in harnessing solar energy, converting sunlight into electricity. Their structure consists of solar cells, typically made from silicon, layered between protective materials. The surface is usually made of tempered glass, which safeguards the inner components from environmental factors. Understanding the fundamental operation of these panels is crucial in addressing issues resulting from damage. Solar panels convert sunlight through the photovoltaic effect, where photons excite electrons within the silicon cells, generating direct current (DC) electricity.

The photovoltaic module’s efficiency relies on multiple factors. These include the quality of materials used, environmental conditions, and maintenance practices. Unfortunately, external factors such as extreme weather, falling debris, or improper installation can lead to damage, necessitating repairs. Familiarity with the panel’s composition and functionality can help diagnose issues more efficiently, leading to targeted repair strategies.

2. COMMON TYPES OF DAMAGE AND THEIR IMPLICATIONS

Recognizing the types of damage is pivotal in developing effective repair solutions. Cracks on the surface can range from hairline fractures to deep breaks that expose the internal components. Hairline cracks may not immediately affect performance, while significant fractures can lead to severe module degradation or complete failure. Delamination occurs when the layers of the panel separate, potentially allowing moisture to penetrate and compromise the solar cells. This condition significantly impacts the panel’s efficiency and longevity.

Weather-related damage is particularly prevalent in areas prone to hail or heavy storms. Hail can leave dents or holes, while excessive heat can cause materials to expand and contract, leading to structural failures. Electrostatic discharge and electrical shorts are other common issues, particularly in systems that experience lightning strikes or surges. Addressing these problems promptly is vital, as delayed repairs can lead to reduced efficiency or complete system failure.

3. SAFETY MEASURES DURING REPAIR

Undertaking repairs on solar panels requires adequate safety precautions. Working with electrical components poses risks, including electric shock. Wearing protective gear such as gloves, goggles, and masks is strongly recommended. Moreover, it’s imperative to disconnect the solar panel from the inverter to prevent any live electrical hazards during the repair process. Proper planning ensures a safer work environment, allowing repairs to proceed without undue risk.

In addition to personal safety, consider environmental conditions. Performing repairs during dry weather minimizes the risk of slipping or damaging components further. Encourage a two-person team whenever possible to improve communication and safety practices. By prioritizing safety, individuals can not only protect themselves but also ensure that the repair process does not exacerbate existing problems.

4. TOOLS AND MATERIALS REQUIRED FOR REPAIR

Equipping oneself with the correct tools and materials is crucial for the successful repair of solar panels. Basic tools include a multimeter, screwdriver set, and utility knife, which assist in diagnosing electrical issues and dismantling damaged components. Adhesives such as silicone sealants or epoxy resins are commonly used for re-sealing edges or adhering broken parts. Ensure these materials are specifically designed for use with solar panels to maintain their integrity.

Additionally, it’s advisable to have a cleaning kit on hand, which may include isopropyl alcohol and microfiber cloths. A clean surface is vital for effective repairs, particularly when gluing components back together. Having a supply of replacement parts can expedite the process; considering that panel designs can vary, it may be beneficial to source OEM (original equipment manufacturer) parts for optimal compatibility and performance. Preparedness enhances the repair process and can lead to a more efficient resolution.

5. STEP-BY-STEP REPAIR PROCESS

Repairing a damaged solar panel involves a systematic approach. First, thoroughly inspect the panel to identify issues. Use a multimeter to assess the voltage output and confirm the type of damage. For cracked panels, documentation with photographs may help guide the repair approach. Next, cleaning the damaged area is crucial. Utilize a gentle cleaning agent and a soft cloth, ensuring no residue or debris will interfere with the repair.

When dealing with cracks, applying a specialized adhesive designed for glass may involve filling the cracks. For delamination, carefully resealing the layers may restore integrity; this may also include replacing the glass if damaged significantly. Allow sufficient time for the adhesive or sealant to cure before reconnecting to the electrical system. Subsequent testing is essential to ensure all repairs are functioning correctly—monitoring voltage output ensures that the panel is operating efficiently.

6. TESTING AND MONITORING POST-REPAIR

Post-repair monitoring is critical to ensuring the longevity of the newly repaired solar panel. Continuous assessment of the electric output provides data on the panel’s performance and is a critical component of maintaining efficiency. Using a monitoring system integrates seamlessly with the solar inverter, giving real-time updates on production levels. Examining the panel frequently for signs of wear and tear will also help enhance overall performance.

Engaging in routine maintenance practices can ensure that small issues do not escalate into significant problems. Regular inspections, including checking for physical damages and cleaning, optimize the panel’s ability to absorb sunlight effectively. Implementing a comprehensive monitoring plan not only safeguards the repaired panel but also maximizes its energy production potential for years to come.

FREQUENTLY ASKED QUESTIONS

WHAT SHOULD I DO FIRST IF I FIND A CRACK IN MY SOLAR PANEL?

If you discover a crack in your solar panel, it is imperative to immediately disconnect the panel from the inverter to prevent any electrical hazards. Carefully examine the crack to assess its severity; if it is a hairline fracture, it may not pose an immediate threat to functionality, but it should still be monitored closely. In contrast, if the crack is extensive and compromising performance, consider consulting a professional for repair options. Document the damage with photographs and gather necessary tools for cleaning and sealing the crack. Finally, if not confident in performing repairs, reaching out to a qualified technician can ensure proper handling.

HOW CAN I PREVENT DAMAGE TO MY SOLAR PANELS IN THE FUTURE?

Preventing damage to solar panels involves implementing multiple proactive measures. Regular maintenance checks are essential to identify wear and tear before they become serious issues. Cleaning the panels periodically to remove dirt, debris, or bird droppings can significantly enhance their efficiency. Furthermore, evaluating the surrounding environment for potential hazards, such as overhanging trees or nearby structures that could block sunlight, is advisable. Utilizing protective coatings may also help minimize damage from hail or other impact-related incidents. Adequate planning and regular assessments serve as effective strategies to protect your investment in solar energy.

IS IT WORTH IT TO REPAIR MY SOLAR PANEL, OR SHOULD I REPLACE IT ENTIRELY?

Determining whether to repair or replace a solar panel depends on the extent of the damage and the associated costs. If damages are minor, such as small cracks or loose connections, repair may be a viable option. Assess the cost of repairs against the investment involved in purchasing a new panel. However, if the panel is experiencing significant degradation or has reached the end of its expected lifespan (typically 25-30 years), opting for a replacement could be more practical and cost-effective in the long term. Consulting with solar energy professionals can provide valuable insight into the most beneficial decision based on individual circumstances.

The process of repairing a broken solar photovoltaic panel requires a collaborative approach that encompasses multiple aspects. First and foremost, identifying the type of damage sustained provides an initial direction for further actions. Understanding common damage types, including cracks, delamination, and environmental impact, equips one with the necessary knowledge for informed decisions. Ensuring safety during repairs is absolutely paramount to protect oneself from potential risks associated with electrical components.

Thoroughly gathering tools and materials streamlines the repair process; this includes having adhesive, cleaning supplies, and replacement parts readily available. By adopting a structured and methodical approach to the repair, including preparation, execution, and post-repair monitoring, one can greatly enhance the longevity and efficiency of the repaired panel. Ultimately, the proactive management and diligent care of solar photovoltaic panels contribute to not only their resilience but also the sustainable utilization of solar energy as a clean and renewable resource.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-repair-a-broken-solar-photovoltaic-panel/