1. REPAIRING A BROKEN SOLAR GENERATOR REQUIRES A STEP-BY-STEP APPROACH, 2. IDENTIFYING THE ISSUE IS CRUCIAL FOR EFFECTIVE TROUBLESHOOTING, 3. SAFETY MEASURES MUST BE OBSERVED TO PREVENT ACCIDENTS, 4. REPLACING DAMAGED COMPONENTS ENSURES LONG-LASTING FUNCTIONALITY. A broken solar generator often results from various factors, including internal damage, weather effects, or user error. Addressing such malfunctions involves careful analysis and repair processes that vary depending on the specific issue.

In-depth understanding of the generator’s components—batteries, inverters, solar panels, and wiring—is essential for effective repairs. For instance, when battery health is compromised, the entire system’s performance deteriorates, often leading to complete shutdowns. Adhering to safety protocols is vital, ensuring you avoid electrical hazards and potential fires. Furthermore, component replacement—when necessary—should be conducted with parts that match the original specifications to maintain efficiency and reliability.

1. COMPONENT ANALYSIS AND IDENTIFICATION OF FAILURE

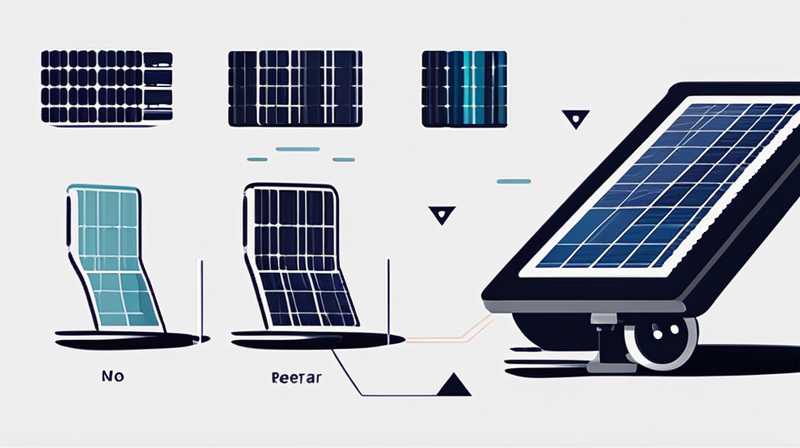

Before embarking on any repair task, one must engage in thorough component analysis. The solar generator’s architecture typically includes several key components: solar panels, batteries, inverters, and charge controllers. Understanding how these elements work together is fundamental. For instance, solar panels convert sunlight into electricity, which is then stored in batteries for later use. If any of these units underperform or fail, the entire system can be rendered inoperable.

In the event of malfunction, initiate the investigation by examining each component individually. Start with the solar panels, checking for physical damage like cracks or disconnections. It’s not uncommon for adverse weather conditions—such as hail or heavy winds—to compromise panel integrity. After inspection, proceed to the batteries. Signs of corrosion or leakage can indicate failure, necessitating immediate replacement. Evaluating the inverter is also critical, as it is responsible for converting direct current (DC) from batteries into alternating current (AC), which powers household appliances. An analytical approach facilitates accurate identification of the problematic area, thereby streamlining the repair process.

2. SAFETY PRECAUTIONS DURING REPAIR

Engaging in repairs without adhering to safety precautions poses risks not only to oneself but also to surrounding equipment. Since solar generators operate at significant voltages, it is pivotal to disconnect all power sources before initiating repairs. This includes unplugging devices connected to the inverter and ensuring solar panels are shielded from sunlight during diagnostic work to prevent electric shocks.

Wearing appropriate personal protective equipment (PPE)—such as gloves, safety glasses, and insulated tools—enhances safety during operations. Gloves protect the hands from sharp edges, harmful chemicals, and potential electrical hazards. Eyewear shields the eyes from flying debris, especially when working on damaged components. When handling batteries, remember that they contain sulfuric acid, which can cause severe injury if spilled. Therefore, ensure that the workspace is equipped with materials for emergency cleanup, including acid neutralizers and safety showers, if applicable. Following these precautions creates a safer environment for conducting essential repairs.

3. TROUBLESHOOTING ELECTRICAL COMPONENTS

Once the outer safety and structural integrity checks are complete, focus shifts to troubleshooting electrical components. Begin by inspecting the wiring for any visible signs of wear, fraying, or corrosion. Wires can deteriorate over time due to heat exposure, moisture, or animal interference, resulting in disrupted power flow. Using multimeters can help assess the continuity and voltage of the electrical circuit within the generator, providing insight into potential failures.

After the inspections, testing the inverter is crucial for functionality. If the inverter isn’t converting power properly, it could result in poor performance or complete system shutdown. This issue can often be identified through error codes displayed on the inverter, which vary by manufacturer. Therefore, consulting the user manual is advisable. Should the inverter fail altogether, replacement should consider the specs of the unit to ensure compatibility. Following a comprehensive testing and troubleshooting protocol establishes a foundation for effective repairs, ensuring the integrity of the solar generator.

4. REPLACING DAMAGED OR FAULTY COMPONENTS

Once problematic components have been identified, the next logical step is replacement of damaged or faulty parts. Begin by acquiring genuine replacement parts that match the specifications of the original components to avoid compatibility issues. Compatibility ensures optimal performance, as incorrect replacements can lead to further malfunctions or efficiency drops.

When replacing batteries, opt for high-quality options with the same voltage rating. This practice preserves the generator’s original power capacity. Pay attention to the physical connection points—making sure to follow polarity guidelines to prevent damaging new batteries. During inverter replacement, ensure that the new device aligns with the generator specifications, focusing on voltage ratings and output capabilities. A meticulous approach to component replacement is paramount, as any oversight can undermine the operational efficacy of the solar generator.

5. MAINTENANCE POST-REPAIR

Once repair work is successfully completed and the solar generator is operational, establish a maintenance routine to prolong its lifespan. Conducting regular checks on the solar panels, batteries, and electrical components can help identify issues before they escalate. Periodic inspection of connections for signs of corrosion assists in ensuring the generator remains efficient and reliable.

Cleaning solar panels regularly ensures they continue to capture sunlight effectively; dirt and debris can significantly diminish performance. Additionally, it’s wise to monitor battery health closely—testing levels, ensuring proper charge cycles, and maintaining optimal environmental conditions. Batteries should be stored in cool environments to prevent heat damage and retain capacity. Implementing these maintenance strategies promotes sustainability in the system, enhancing overall performance.

6. COMMON ISSUES AND THEIR SOLUTIONS

Throughout the lifespan of a solar generator, several recurring issues might be encountered. Understanding these common challenges can contribute significantly to effective troubleshooting. For instance, a frequent issue is underperformance due to shading on solar panels. Identifying trees or structures obstructing sunlight allows users to take corrective action, such as relocating panels or trimming vegetation.

Another common issue is battery degradation—over time, batteries may lose their capacity to hold charge effectively. If this is diagnosed, replacing the batteries is often the optimal pathway to restore functionality. Users might also encounter problems with the charge controller, which could exhibit malfunction due to electrical surges. Diagnosing and replacing faulty controllers is crucial for maintaining overall efficiency in energy conversion and storage. Recognizing and addressing these challenges enhances user experience and ensures reliability in energy provision.

7. TESTING AND VALIDATING THE REPAIR WORK

Following the completion of any repair endeavors, it’s essential to test the solar generator thoroughly to validate the repair work. This stage verifies that all systems function as intended. Begin by re-connecting everything and ensuring all connections are secure. Test the solar panels’ output again under direct sunlight to ascertain they are generating adequate power.

Next, monitor the inverter’s functionality by running appliances and observing performance. Checking the battery’s charge level and cycle abilities is also imperative. Effective testing encompasses simulated usage scenarios, ensuring that the generator operates under normal loads. If all components successfully perform without difficulties, you can be confident that the repairs were effective, paving the way for reliable usage in the future.

FREQUENTLY ASKED QUESTIONS

1. WHAT ARE THE MOST COMMON CAUSES OF SOLAR GENERATOR FAILURE?

Various factors can lead to the malfunction of solar generators. Environmental conditions—such as extreme temperatures, humidity, and weather-induced damage—pose significant risks. Additionally, user error during operation or installation can result in performance issues, like incorrect wiring or mismanagement of battery charging cycles. Regular wear and tear is another factor, particularly with older generators that may require battery or inverter replacement over time. To mitigate these risks, it’s crucial to conduct annual maintenance checks and replace components as needed.

2. HOW DO I KNOW IF MY SOLAR GENERATOR BATTERY IS FAULTY?

Identifying a malfunctioning battery can involve several diagnostic steps. Look for indicators such as diminished performance, excessively low charge retention, or physical signs like corrosion or swelling. Monitoring voltage readings can help—charging batteries should reflect proper voltage levels consistent with their rating. Routine testing and recording of performance metrics can also pinpoint irregularities, allowing for timely identification of faulty batteries. Timely interventions are essential to maintain optimal generator functionality.

3. CAN I REPAIR A SOLAR GENERATOR MYSELF, OR SHOULD I HIRE A PROFESSIONAL?

Whether to undertake repair tasks personally or seek professional help depends on one’s skill level and comfort with electrical components. If familiar with the mechanics and safety protocols involved, DIY repairs can be both cost-effective and satisfying. However, for those lacking experience, hiring a certified technician ensures safety and optimal repairs. For complex issues—particularly involving electrical systems—professionals possess the expertise necessary to handle repairs efficiently and effectively. Always assess the situation carefully before proceeding with repairs.

The effective restoration of a malfunctioning solar generator revolves around meticulous analysis, thorough problem identification, and strategic component replacements. An understanding of the delicate interplay among the generator’s various parts, coupled with strategic maintenance plans, ensures long-term performance. Safety precautions remain paramount throughout the repair process to prevent accidents and injuries. Additionally, by recognizing common issues and adopting a proactive maintenance approach, users can significantly enhance the reliability of their solar generators. Structuring repairs thoughtfully and with a hands-on mindset empowers users to maximize their investment in renewable energy solutions. Ultimately, the commitment to proper care and upkeep promotes sustained efficiency, making solar generators a dependable choice for clean energy alternatives.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-repair-a-broken-solar-generator/