Repairing a broken solar cable involves a thorough understanding of the components and the necessary steps for effective restoration. The following key points are essential: 1. Safety precautions must be taken, ensuring that the solar system is deactivated to prevent electric shocks. 2. The correct tools and materials, such as heat-shrink tubing and electrical connectors, are necessary for the repair. 3. A systematic approach is vital, focusing on identifying the damage, preparing the cable ends, and securely connecting the cables. 4. Testing the repaired section is crucial to ensure functionality and integrity before reactivating the solar system.

One detailed aspect is the importance of utilizing heat-shrink tubing during the repair process. This tubing not only serves to insulate and protect the connections but also prevents moisture ingress and potential corrosion, which can significantly impact the longevity and efficiency of the solar cable.

UNDERSTANDING SOLAR CABLES

Solar cables are specialized conductors designed to transmit direct current (DC) generated by solar panels to inverters or batteries. Understanding their construction and functionality is crucial for effective repairs. Composed typically of copper or aluminum strands, these cables are insulated with durable materials resistant to UV radiation, extreme temperatures, and weathering. The quality of insulation is vital as it serves not only to protect the wiring from external factors but also to ensure safety by preventing electrical shocks.

When assessing solar cables, one must recognize the distinction between two main types: photovoltaic (PV) cables and AC cables. PV cables are designated for the DC output of solar panels and are engineered to withstand the solar installation’s specific environmental conditions. In contrast, AC cables are used for the alternating current that flows from the inverter to the electrical system of the building. Thus, ensuring compatibility and integrity before attempting any repair is essential.

DIAGNOSING THE DAMAGE

Proper diagnosis is foundational to effectively repairing a broken solar cable. Visual inspections can often reveal some readily apparent signs of damage, such as exposed wires or fraying insulation. Identifying the exact location of the break is necessary before proceeding with any repair work. This step will involve tracing the cable from its entry point to its endpoint, examining for discoloration, breaks, or signs of wear that may indicate electrical shorts.

Additionally, employing multimeters can significantly enhance the diagnostic process. By measuring the voltage and continuity across the cable, one can ascertain whether the cable is indeed compromised. A reading of zero volts or infinite resistance may hint at a complete break in the wire. Understanding these diagnostics allows for an informed approach to restoration, avoiding unnecessary repairs and expediting the process.

GATHERING TOOLS AND MATERIALS

Embarking on a solar cable repair necessitates a precise procurement of tools and materials. Essential items include wire strippers, soldering equipment, heat-shrink tubing, and high-quality electrical connectors. Selecting the right tools not only facilitates a smoother repair process but also contributes to the long-term reliability of the repairs.

As for the materials, one must prioritize using components that are compatible with the existing solar wiring. UV-resistant heat-shrink tubing is critical to provide insulation and protection against environmental factors. Additionally, connectors that are both waterproof and corrosion-resistant will enhance the reliability of the repaired section. Compromised materials can lead to future vulnerabilities, thus choosing high-quality items is essential for effective repairs.

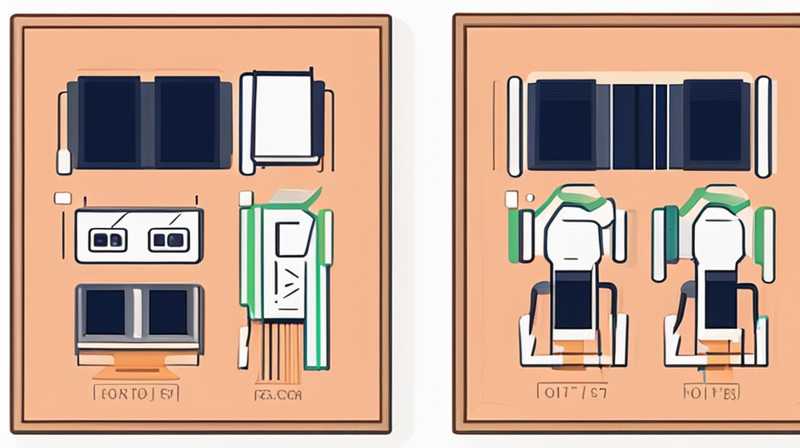

REPAIRING THE CABLE

The actual process of repairing solar cables entails several systematic steps. Initially, ensuring that the solar system is completely deactivated is paramount for personal safety. Once the system is off, gently strip away the broken section of the cable using wire strippers. Care should be taken to remove just enough insulation to expose the copper strands while minimizing any further damage to the wire itself.

After stripping both ends, twist the exposed ends together securely to form a solid connection. It is advisable to use soldering for a more robust and permanent repair. Once soldering is complete, slide the heat-shrink tubing over the exposed area and apply heat to secure it tightly around the joint. This phase is crucial as it ensures that the repair is protected from moisture and physical damage, significantly extending the lifespan of the repaired cable.

TESTING REPAIRED CONNECTIONS

Following completion of the repair, post-repair testing is a critical phase to ensure that the cable is functioning correctly. Utilizing a multimeter, one must check the continuity of the cable to confirm that the connection is intact. If continuity is present and voltage is consistent, this indicates a successful repair.

Once electrical testing verifies functionality, reactivation of the solar system can proceed. This is an important step as it allows for the final assessment of the cable under operational conditions. Close monitoring during this phase is advisable, assessing for any unusual sounds, smells, or readjustments needed in the connections. Implementing this testing ensures that the repair meets the efficiency standards required for effective solar power generation.

MAINTAINING SOLAR CABLES POST-REPAIR

Prevention is better than cure when it comes to solar cable maintenance. Regular inspections can identify potential issues before they escalate into larger problems. Routine checks are recommended, particularly after severe weather conditions, which may cause undue wear or even damage to exposed cables.

In addition to visual inspections, maintaining a clean environment free from debris and vegetation will also prolong cable life. Should any abrasions or signs of wear be spotted, it is recommended to address them immediately, before they lead to potential system failures or safety hazards. Proactive maintenance ensures that solar energy systems remain efficient and reliable for years to come.

COMMON ISSUES WITH SOLAR CABLES

Understanding frequent challenges associated with solar cables also provides insight into repairs and preventive measures. One prevalent issue is UV degradation, wherein prolonged exposure to sunlight can weaken the cable’s insulation. Regularly inspecting insulation for cracks or fading can help catch this problem early.

Another common dilemma is moisture intrusion, which can lead to electrical shorts and eventual failure of the solar system. Implementing proper sealing methods, such as heat-shrink tubing and waterproof connectors, can mitigate this risk significantly. Awareness of common issues allows for a more comprehensive approach to repairing and maintaining solar cables, resulting in a more resilient solar power system.

RENEWABLE ENERGY AND SUSTAINABILITY

Embracing renewable energy sources like solar power signals a broader commitment to sustainability, not only for individuals but for communities and nations alike. By ensuring that solar installations remain operational and efficient through proper maintenance and repairs, users participate in reducing reliance on fossil fuels. Each repaired solar cable enhances the overall sustainability of the energy system.

Moreover, a successful repair contributes to a decrease in electronic waste as it promotes extending the life of existing installations rather than replacing entire systems. Responsible stewardship of renewable energy resources underscores a commitment to protecting the environment for future generations while fostering a culture of innovation in renewable technology.

SAFETY MEASURES

When repairing or maintaining solar cables, safety must always be prioritized. Proper personal protective equipment (PPE), including gloves and safety goggles, should be worn to minimize injury risks. Additionally, working with a partner is advisable, particularly when dealing with high-voltage systems, as immediate assistance may be necessary in emergencies.

Furthermore, ensuring that repair work is conducted in dry conditions helps reduce the risk of electric shock. Remaining cognizant of the guidelines for handling electrical equipment will significantly minimize accidents and injuries during the repair process.

COMMON INQUIRIES ABOUT SOLAR CABLE REPAIRS

WHAT TO DO IF I SUSPECT A SOLAR CABLE IS DAMAGED?

If there are suspicions of a damaged solar cable, the immediate step is to deactivate the solar system to ensure safety. Conducting a visual inspection for visible signs of wear or damage is crucial. Utilizing a multimeter to test continuity and voltage can confirm the existence of damage. If definite issues are found, consulting a professional or proceeding with repair as previously detailed is advisable. It is vital to act quickly to prevent further damage or safety hazards.

HOW OFTEN SHOULD SOLAR CABLES BE INSPECTED?

The frequency of inspections should depend on various factors; however, an annual inspection is typically recommended. High-stress conditions like extreme weather or prolonged exposure to sunlight might warrant more frequent checks. Look for abrasions, discoloration, and integrity of insulation. Daily checks during periods of severe weather can also prevent potential irreversible damage. Keeping a maintenance log can be beneficial for tracking the condition and performance of solar cables.

CAN I REPAIR SOLAR CABLES MYSELF?

Yes, it’s possible to conduct repairs on solar cables independently, provided you have the right tools and knowledge. Familiarity with the safety measures and repair processes is essential. Relying on manuals and tutorials can improve your understanding of proper techniques. However, if there’s any uncertainty or complexity involved, seeking professional guidance is advisable to ensure safety and effectiveness.

In summary, repairing a broken solar cable is a multifaceted task that requires careful consideration of several factors. Following a well-defined process allows for a safe and effective restoration of functionality. Adhering to safety protocols by deactivating solar systems, diagnosing damage accurately, and utilizing the correct tools and materials is essential for successful repairs. The repair process itself entails stripping damaged sections, reconnecting cables, and completing the joint with heat-shrink tubing. Testing repaired areas ensures cables function as intended before reactivation of the system. Regular inspections following repairs reinforce the cable’s integrity and prolong its life, contributing to the overall sustainability of solar energy systems. By understanding and addressing common issues, users engage in responsible energy stewardship, crucial for combating climate change. Proper knowledge, skills, and preventative maintenance can elevate the performance of solar installations and support the transition to renewable energy.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-repair-a-broken-solar-cable/