Understanding the procedure to restore a defective solar angle valve necessitates a careful approach. 1. Recognizing the symptoms of malfunction, 2. Gathering the necessary tools and materials, 3. Following a systematic repair method, 4. Testing the repair for effectiveness. Among these, the first step is crucial as it ensures the correct diagnosis of the issue, preventing unnecessary replacement or repairs.

1. UNDERSTANDING THE SOLAR ANGLE VALVE

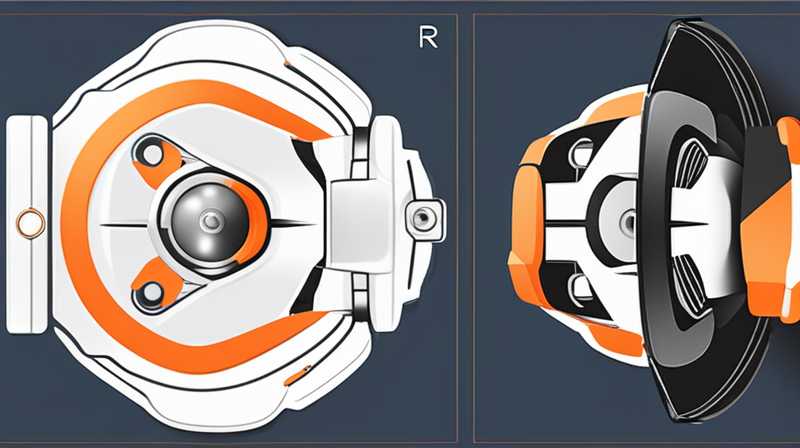

Proper comprehension of the solar angle valve and its function within a solar heating system is essential. An angle valve typically controls the flow of fluid within a system, allowing for precise regulation of temperatures and ensuring optimal performance. In solar thermal systems, these valves play a pivotal role in maintaining efficiency by directing heated water from collectors to storage tanks.

Angle valves can be made of various materials, often including brass, stainless steel, or plastic, each offering unique pros and cons in terms of durability and thermal conductivity. A thorough understanding of the specific purpose of the valve in question can guide the approach for repairs or replacement, minimizing disruptions to the system’s overall functioning. Any minor issues may lead to significant energy losses or system inefficiencies, underscoring the importance of timely repairs.

2. SIGNS OF MALFUNCTION

Identifying prominent signs of malfunction is the next step post-understanding the valve’s function. 1. Leaking water around the valve, 2. Inconsistent water pressure, 3. Inability to heat water, 4. Strange noises during operation. Each of these indicators may signify specific problems requiring varying solutions.

For instance, a leak may suggest deterioration in the valve’s seals or cracks within the housing. Meanwhile, fluctuating water pressure typically arises from blockages or internal wear. Recognizing these indicators early can prevent more extensive damage or costly repairs later on. Therefore, regular maintenance checks are advised, allowing homeowners or technicians to catch signs of wear before they evolve into serious issues.

In situations where the valve does not seem to be functioning correctly, it is pivotal to not only check the angle valve itself but also the upstream and downstream components. This holistic approach ensures that one does not mistakenly attribute problems to the valve when they may lie elsewhere within the system.

3. TOOLS AND MATERIALS REQUIRED FOR REPAIR

Gathering the necessary tools and materials for repairing an angle valve involves compiling both basic and specialized items. 1. Wrenches for valve removal, 2. Replacement seals or O-rings, 3. Thread sealant tape, 4. Cleaning materials. Each of these components plays a vital role in the repair process.

Wrenches are essential for loosening and tightening the valve connections. Depending on the model, appropriate sizes will vary. Furthermore, purchasing compatible replacement seals or O-rings is crucial as these often wear out and can lead to leaks if not replaced. Thread sealant tape assists in creating a watertight seal when reassembling the connections, minimizing the chance of future leaks.

Cleaning materials are equally important, as thorough cleaning of the valve and surrounding areas ensures the effective application of new seals. This foundational preparation plays a significant role in ensuring that the repair proves successful and that future maintenance remains manageable.

4. REPAIR PROCEDURE

Following a systematic approach for the repair process enhances success rates. 1. Turn off the system and drain the water, 2. Remove the faulty angle valve, 3. Clean the valve housing and connections, 4. Install replacement seals and reattach the valve, 5. Restore water supply and check for leaks.

To begin, it is imperative to switch off the entire system, ensuring safety and preventing further water loss. Draining excess water relieves pressure within the pipes, making the disconnection process easier. Once the system is depressurized, one can carefully remove the existing angle valve using the appropriate wrenches, taking care not to damage nearby components during this process.

Cleaning the valve housing thoroughly ensures that debris or old sealant does not interfere with the newly installed seals. Using a brush and cloth, one should clear both the valve seat and any threads where connections will be made.

Introducing replacement seals is a critical phase; taking time to ensure that they are compatible and seated properly can prevent future issues. Subsequently, reattaching the valve should be done meticulously, ensuring that all threaded connections are aligned correctly before applying sealant tape and tightening the joins.

Finally, carefully restoring the water supply will allow for testing of the repair. At this juncture, monitoring for leaks or irregular operations is advisable as this final check will confirm the success of the repair.

5. TESTING AND MAINTENANCE

Assessing the effectiveness of the repair plays a crucial role in the longevity of the solar angle valve. 1. Monitor for leaks, 2. Observe system pressure, 3. Conduct routine maintenance checks. Each of these steps is necessary to ensure a fully functional valve and system.

Post-repair, one should carefully monitor the valve for any signs of leaks. This allows for immediate correction should an issue arise. Observing system pressure can also reveal functional issues. If pressure varies significantly from projected levels, this may indicate an inadequate seal or the need for further investigation.

Regular maintenance checks complement a well-functioning repair, allowing for early detection of future problems and ensuring that the solar heating system operates at peak efficiency. This comprehensive approach guarantees optimal performance and longevity of all components, facilitating energy savings and reliability.

COMMON INQUIRIES

WHAT IS A SOLAR ANGLE VALVE?

A solar angle valve is a specialized component within solar thermal heating systems designed to manage fluid flow. Positioned typically as part of the pipeline from solar collectors to storage tanks, this valve allows for the regulation of hot water transport, thus optimizing energy efficiency. The construction materials may vary, influencing durability, thermal properties, and efficiency. Understanding the specific role and operation of an angle valve can contribute to the effective management and usage of solar energy resources.

HOW CAN I DETERMINE IF MY SOLAR ANGLE VALVE IS FAULTY?

Identifying a malfunctioning solar angle valve involves recognizing certain signs. Key indicators include leaks at the valve’s connections and unexpected temperature or pressure fluctuations within the system. Regular maintenance checks can facilitate early detection of wear or obstructions that may indirectly affect the valve’s performance. Observing the valve during operation can also reveal irregularities, ensuring that interventions are made in a timely manner before more significant issues develop.

HOW OFTEN SHOULD I PERFORM MAINTENANCE ON MY SOLAR ANGLE VALVE?

Routine maintenance is essential for ensuring optimal performance. It is typically advisable to check the solar angle valve and associated components at least once every six months. However, this frequency may vary based on environmental factors, usage intensity, and system complexity. Regular checks can help in identifying minor issues before they manifest into significant problems, thereby prolonging the life of the valves and ensuring the system operates as intended throughout its lifetime.

In summary, when considering the restoration of a compromised solar angle valve, several essential procedures come to the forefront. Recognizing the significance of identifying symptoms is paramount; understanding both the valve’s purpose and signs of malfunction will showcase the urgency for repair. Properly equipping oneself with the needed tools and materials ensures that the process unfolds smoothly, allowing skillful execution of the repair steps. Testing the effectiveness of the repair and committing to ongoing maintenance can optimize the performance of the entire solar heating system. The significance of diligent care and proactive measures cannot be overstated; these practices safeguard both the valve’s condition and overall system performance, leading to increased efficiency and longevity in utilizing solar energy resources.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-repair-a-broken-solar-angle-valve/