To successfully remove the valve located beneath the solar panel, specific steps and precautions must be adhered to. 1. Safety is paramount; ensure the system is powered down, and all precautions regarding electrical components are observed. 2. Utilize proper tools such as wrenches and pliers for efficient removal. 3. Take note of the orientation and connection styles of the valve to ensure proper reinstallation if needed. 4. Understand the type of valve in use; different systems may employ varying designs, necessitating tailored approaches.

Step 5: Address any leaks or residual pressure before detaching the valve, using caution to avoid water damage. Removing the valve may appear straightforward, but awareness of potential complications and conducting the procedure with diligence will ensure a smooth experience.

UNDERSTANDING THE SOLAR PANEL SYSTEM

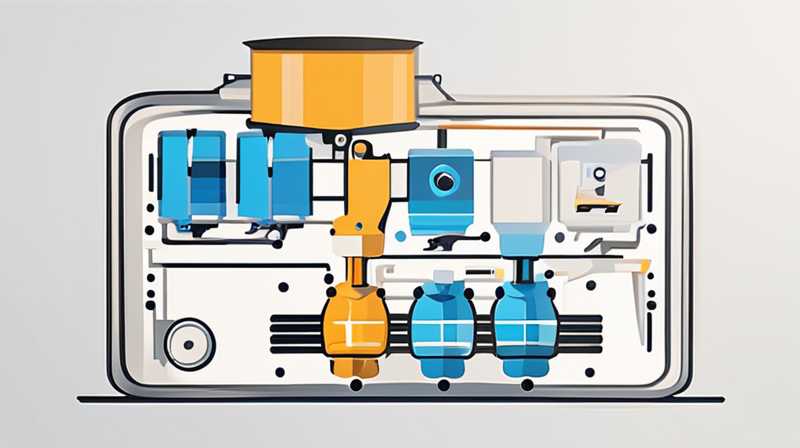

Solar panel systems incorporate multiple components working in concert to harness solar energy effectively. At the heart of these systems lies the valve, which plays a crucial role in managing the flow of fluids required for thermal transfer. To comprehend the process of removing this valve, one must first grasp the overall setup of the solar panel system, including its mechanical, electrical, and fluidic components.

In essence, solar panels absorb sunlight, converting it into usable electricity. For solar heating systems, the fluid transport mechanism is vital as it circulates heated fluid to either a storage tank or to directly heat a passage. The valve acts as a control mechanism, preventing backflow and enabling maintenance of optimal operating conditions.

TOOLS AND PREPARATION

One must be adequately equipped with the right tools before embarking on the valve removal process. Proper tools include adjustable wrenches, screwdrivers, and pliers. Safety gear, including gloves and goggles, enhances personal protection during the procedure.

Equally important is the preparation of the workspace. Ensure that the area is clear of obstructions and that access to the solar panel and the valve is unobstructed. Understand the valve’s position relative to surrounding equipment such as pipes and electrical connections. Documenting the layout before disassembly may facilitate easier reassembly later, particularly for those unfamiliar with the arrangement.

DRAINING THE SYSTEM

Before initiating any disassembly, draining any residual fluids from the system is critical. This action serves multiple purposes, notably preventing potential water damage and reducing the risks of spills or leaks during the removal.

Begin by locating the drainage valve, if available, or creating a route for the fluid to exit safely. Using buckets or containers to catch any draining fluid is advisable. Throughout this process, maintaining communication with any team members may be essential to ensure that everyone is aware of potential hazards.

POWER DOWN AND SAFETY MEASURES

Powering down the entire system is a crucial safety measure before any physical work is performed. This act ensures that no electronic components can unintentionally energize, thus working to minimize the risk of electric shock.

Once powered down, establish a safety perimeter around the workspace and notify anyone nearby regarding the task at hand to avoid accidents. Confirm the lack of live electrical connections to ensure a safe environment for removing the valve.

REMOVING THE VALVE

The valve removal phase requires precision and care. Begin by loosening any connections using suitable tools, applying adequate force without damaging surrounding components. It’s essential to remember the orientation of fittings and hoses, as their locations may impact reinstallation.

Once connections are loosened, gently apply force to detach the valve from its mounting. Maintaining care throughout this step is paramount to preventing damage to the valve or associated piping.

INSPECTING THE VALVE AND CONNECTIONS

After removing the valve, conducting a thorough inspection is imperative. Look for any signs of deterioration or corrosion that could compromise system performance. Evaluating all connections while having the valve removed provides an opportunity to assess potential vulnerabilities in the entire system.

If any visual damages are detected, consider replacing sections of piping or connections to improve efficiency. Having the valve off leaves a unique window of opportunity to optimize the solar panel assembly, ensuring peak performance.

REPLACING OR REINSTALLING THE VALVE

Upon completing any necessary inspections and repairs, the valve may either be reinstalled or replaced based on assessment results. Ensure that new components are compatible with existing hardware while following manufacturer specifications.

During reinstallation, reconnect various fittings and seals slowly. Attention to detail is crucial, as improper reconnections may lead to leaks or inefficiency. Following up with tightening connections adequately will establish a reliable, leak-proof assembly.

POST-REASSEMBLY CHECKS

Once the valve has been successfully reinstalled or replaced, execute series of tests to ensure proper functionality. Check the entire system for leaks and to confirm that all electrical connections are secure and in working order. Activate the solar panel system again, monitoring its operation for any irregularities.

Should any issues be present post-reattachment, further investigation into repairs may be necessary. This process reaffirms the importance of diligence during both removal and reinstallation that can lead to long-term system reliability.

MAINTENANCE AND LONG-TERM PERFORMANCE

To ensure continued optimal performance, establish a regular maintenance schedule for the solar panel system and its components. Careful monitoring and periodic checks on the valve and related plumbing can prevent unexpected shutdowns or failures due to wear and tear.

Each season may bring unique challenges; be proactive about any changes in performance derived from environmental factors or operational conditions. Staying vigilant will ensure constant energy production and prolong the lifespan of the solar panel system.

CONSIDERATIONS AND CONCLUSIONS

Working on a solar panel system requires commitment to safety, adherence to correct procedures, and thorough investigation into associated components. Proper preparation, tool management, and a cautious approach can make the valve removal process efficient and effective. Equally, the importance of the valve in controlling system flow and performance cannot be understated. After replacing or reattaching the valve, never overlook the significance of routine inspections and maintenance to uphold optimal system functionality. Moreover, understanding the mechanics of solar panels and their interrelated components fosters a well-functioning installation, contributing to sustainable energy solutions. As systems evolve and technology improves, the knowledge gained from performing routine valve maintenance will equip owners to manage both current systems and any future advancements. Take the time to become knowledgeable about each element of your solar setup, and enhance its longevity and reliability through careful attention and proactive management.

COMMON INQUIRIES

WHAT TOOLS ARE NEEDED FOR REMOVING A VALVE UNDER A SOLAR PANEL?

The removal of a valve under a solar panel requires specific tools for efficiency and safety. Essential tools include adjustable wrenches, screwdrivers, and pliers, ideally suited for various fittings and connections. Safety precautions should never be neglected, and protective equipment—gloves, goggles, and perhaps a hard hat—should always be donned before engaging in the task. Prior to commencing, an assessment of the space, tools, and required actions will create a clearer pathway for success.

IS IT SAFE TO WORK ON A SOLAR PANEL SYSTEM IF I’M NOT AN EXPERT?

While working on a solar panel system may appear simple, the risks associated with electrical and fluid-based components underscore the importance of expertise. It is advisable to consult professionals for tasks beyond basic maintenance. Should one choose to proceed, thorough understanding and preparation must be prioritized for the sake of safety. Engaging with tutorial resources or guidelines can reduce ambiguity during procedures, bolstering confidence while minimizing hazards.

HOW OFTEN SHOULD I CHECK THE VALVE UNDER MY SOLAR PANEL?

The frequency of checks on the valve under a solar panel may depend on system usage and environmental factors. As a general guideline, conducting inspections at least twice a year ensures detection of any potential issues before they develop into major problems. Areas exposed to extreme weather conditions, debris, or regular operational stress should warrant additional inspections. Keeping records of checks and any potential maintenance actions can aid in identifying patterns that may necessitate closer scrutiny.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-remove-the-valve-under-the-solar-panel/