To effectively detach the upper cover of a solar solenoid valve, follow these essential steps: 1. Understand the components involved, ensuring clear differentiation between the upper cover and the underlying parts, 2. Gather necessary tools, which may include screwdrivers or wrenches tailored to your specific valve model, 3. Follow safety protocols, including disconnecting power sources to prevent electrical hazards, and 4. Inspect and clean the valve thoroughly before reassembly to promote optimal function.

- UNDERSTANDING THE SOLAR SOLENOID VALVE

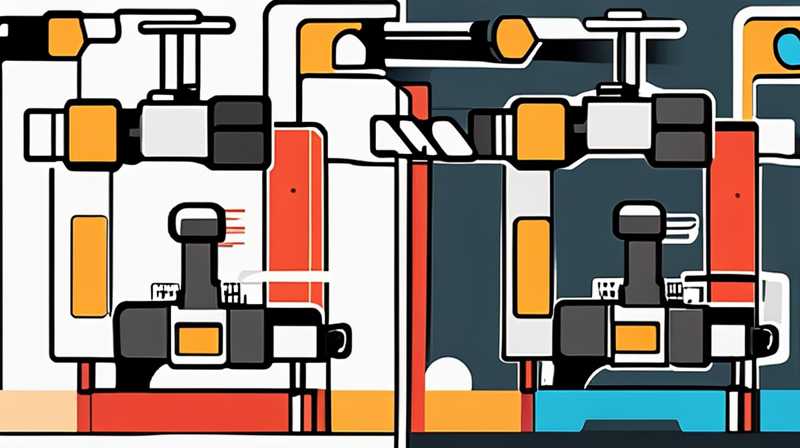

Solar solenoid valves serve a pivotal role in the management of fluid flow within solar heating systems, enabling or obstructing passage based on electrical signals. Their function is integral in maintaining efficient water circulation, which ultimately affects the overall performance of solar thermal setups. This valve consists of a coil, a plunger, and multiple sealing components, all encased within an upper cover.

In order to successfully remove the upper cover, it is crucial to comprehend how the solenoid valve operates. The solenoid itself, essentially a coil of wire, generates a magnetic field when electrified, prompting the plunger to move. This action either opens or closes the valve. Familiarity with these internal mechanisms can facilitate a smoother disassembly process.

- GATHERING NECESSARY TOOLS

Before embarking on the process of removing the upper cover, it is paramount to assemble the right tools. An array of tools ensures that any potential obstacles can be addressed efficiently. Common tools include screwdrivers—both flathead and Phillips—to unfasten screws and bolts that may secure the upper cover to the valve body. Additionally, adjustable wrenches may be required for components that aren’t easily gripped.

Inventorying tools beforehand avoids interruptions during the process. If the specific valve model has unique fasteners, it may be necessary to research additional tools tailored to those components. Ensuring access to high-quality, durable tools not only expedites the task at hand but also minimizes the risk of causing damage to any parts of the valve.

- SAFETY PROTOCOLS

Prior to initiating the removal process, applying safety precautions is imperative. Begin by disconnecting the power supply to the solar system. This halts any potential electrical hazards that could result from inadvertent activation of the solenoid valve. Moreover, in conjunction with electrical safety, handling components with care can prevent physical injuries related to sharp edges or dropped tools.

Beyond personal safety, consider protective gear, including gloves and safety goggles. Such equipment is designed to safeguard against accidental cuts and potential debris. Ensuring a clear workspace further helps in minimizing risks of trips or falls, particularly when maneuvering around complex layouts often found in solar installations.

- PROCESS OF REMOVING THE UPPER COVER

With tools at the ready and safety measures in place, the next step is to begin the physical disassembly of the solar solenoid valve. First, inspect the upper cover for any visible fasteners. Using the appropriate screwdriver, proceed to systematically unscrew and remove these components. Pay attention to the sequence of removal, as a methodical approach ensures reassembly is straightforward.

Following the unscrewing phase, if the cover remains secured, apply gentle pressure to ascertain whether any additional clips or latches exist. Using a plastic prying tool can minimize damage to the valve casing, allowing for a cleaner extraction of the upper cover. Patience and subtlety are often required during this part of the process, as forcing components can lead to damage.

- CLEANING AND INSPECTING COMPONENTS

Once the upper cover is successfully removed, it’s an opportune moment to clean and inspect all components contained within. Debris accumulation can drastically hinder the performance of the solenoid valve, leading to malfunctions or inefficient operation. Utilizing a soft brush or compressed air can help dislodge and remove dirt or foreign particles.

As you inspect the internal mechanisms, pay specific attention to the condition of the plunger and sealing components. Signs of wear, such as cracks or distortions, may necessitate replacement to ensure continued optimal function. Identifying wear early can prevent larger complications that may arise during use.

- REASSEMBLY OF THE UPPER COVER

Following cleaning and inspections, reassembly of the upper cover involves retracing the steps implemented during disassembly, albeit in reverse order. Begin by carefully placing the upper cover back onto the valve body, ensuring any alignment markings are observed to facilitate correct positioning.

Reinsert screws, securing them evenly to avoid undue stress on any particular part of the cover. It is beneficial to apply equal pressure while fastening to maintain strict alignment and ensure a proper seal is formed. Any digital torque setting available on your tools can be advantageous here, as it helps maintain consistency across all fastening points.

- POST-REMOVAL CHECKS

Once reassembly is complete, it’s prudent to conduct post-removal checks to affirm that everything is functioning as intended. Reconnect power sources cautiously, and activate the solar thermal system while observing the operation of the solenoid valve. Listen for any irregular sounds that might indicate improper assembly or lingering debris within the system.

Further, monitor the fluid flow to ensure there are no leaks, which could signify an improperly sealed upper cover or issues with connections that may have shifted during the process. Completing this final verification ensures that the entire process, from removal to reinstallation, was successful.

FREQUENTLY ASKED QUESTIONS

WHAT IS A SOLAR SOLENOID VALVE?

A solar solenoid valve is a device that regulates the flow of fluid in solar thermal systems by using electromagnetic forces. When electrical energy passes through the coil of the solenoid, a magnetic field is generated, drawing a plunger that either opens or closes the valve. This mechanism ensures that water flows optimally in response to temperature changes or system demands. It is an essential part of maintaining the system’s efficiency, directly influencing heating performance and sustainability efforts in solar energy utilization. Through routine maintenance and checks, this component can help prevent issues that may arise from wear, leading to greater longevity of the solar system.

HOW OFTEN SHOULD SOLENOID VALVES BE MAINTAINED?

Regular maintenance of solenoid valves is critical for the effective operation of solar thermal systems. It is advisable to conduct inspections annually, especially before the peak solar season, ensuring all components function optimally. During these inspections, check for any signs of wear, dirt accumulation, and the overall integrity of the valve. If the system is in heavy use or located in harsh environments, more frequent checks every six months may be warranted. Implementing a routine maintenance schedule can effectively identify and address issues early, ultimately ensuring smooth and efficient operation throughout the lifetime of the solar thermal system.

CAN I REPLACE SOLENOID VALVES MYSELF?

Replacing solenoid valves can typically be accomplished by motivated individuals familiar with basic plumbing and electrical work. Prior understanding of the specific system is essential, as different systems may have unique requirements and components. Following proper safety protocols, such as disconnecting power and flushing out any fluid from the system, is vital. Moreover, consulting user manuals and instructional guides during the process ensures adherence to best practices. However, for those who are unsure or inexperienced, seeking the assistance of a qualified technician can mitigate the risks of improper installation and ensure optimal performance.

FINALE REMARKS

Detaching the upper cover of a solar solenoid valve requires a systematic approach, understanding of the components, and thorough application of safety protocols. The outlined steps foster a streamlined process that not only achieves the objective but also emphasizes preventative maintenance. Each phase from understanding the solenoid’s function to ensuring all components are clean and properly reassembled plays a critical role in the longevity and efficiency of solar thermal systems.

Through careful preparation and execution, individuals can successfully navigate the challenges associated with valve maintenance. Engaging regularly with the mechanism deepens overall appreciation and can prevent small issues from escalating into major complications. Essential knowledge gained through hands-on experience enhances future maintenance tasks, forging a pathway to continued success in solar energy utilization.

Adapting this meticulous approach transforms what could be perceived as a daunting task into a manageable endeavor, fostering confidence for current and future valve operations. Emphasizing best practices not only encourages self-sufficiency but also ultimately contributes to the broader objectives of sustainable energy management.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-remove-the-upper-cover-of-solar-solenoid-valve/