Removing a solenoid valve from a solar energy system involves several key steps to ensure efficiency and safety. 1. Ensure the system is powered down, as working on an energized system can lead to injuries or damage. 2. Identify the valve’s connection points by tracing the pipeline linked to it; it’s vital to note whether the connections are threaded, compression, or welded. 3. Prepare necessary tools such as wrenches, screwdrivers, and safety gear before commencing. 4. Follow disassembly procedures carefully to prevent any unintended leaks or damage to adjacent components. Once these points are understood, proper execution of the removal process can be achieved.

1. UNDERSTANDING THE FUNCTION OF A SOLENOID VALVE

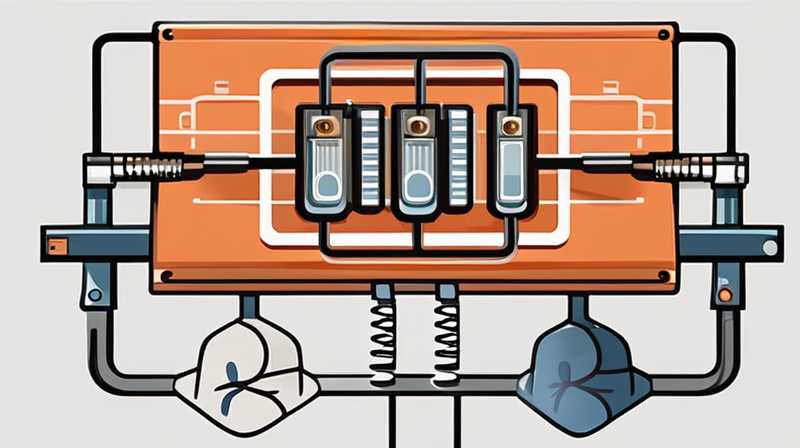

A solenoid valve is a critical component in many solar energy systems, playing a vital role in controlling the flow of liquid or gas within the system. These valves operate using electromagnetic coils, which actuate to open or close the valve. When voltage is applied to the solenoid coil, it creates a magnetic field that attracts a plunger, which in turn shifts the valve mechanism. Understanding this function is crucial, as improper handling during removal can lead to damage.

Solenoid valves can be designed for various applications within a solar energy setup, such as controlling the flow of heat transfer fluids or managing storage tanks. Different types of solenoid valves exist, including normally closed, normally open, and dual-function variants. Each type serves a specific function, and the choice of valve can impact the efficiency and reliability of the entire system. Recognizing the specific type of solenoid valve in use is essential before attempting to disconnect it.

2. SAFETY PRECAUTIONS BEFORE REMOVAL

Ensuring safety is paramount when working on any aspect of a solar energy system, especially when dealing with electrical components. De-energizing the system should be the first step whenever maintenance or removal of any part is undertaken. This involves turning off power sources and using lockout/tagout procedures to prevent accidental re-energizing. Moreover, professional guidance or consultation can prove invaluable, particularly for complex systems.

Wearing suitable personal protective equipment is also essential. Gloves, goggles, and appropriate clothing can protect against accidental spills or contact with broken components. In addition, if the system has been in operation, considerations should be made regarding the residual heat in pipes or components, necessitating caution when handling parts.

3. TOOLS AND EQUIPMENT REQUIRED

Before embarking on the task of removing a solenoid valve, it’s important to gather all necessary tools and equipment to facilitate a smooth operation. Essential tools typically include various wrenches, screwdrivers, a pipe cutter, and possibly a soldering iron, depending on the type of fittings used. Having the right tools on hand ahead of time can help mitigate delays and simplify the disassembly process.

Beyond tools, there may be a need for replacement parts, such as seals or fittings. Over time, components may become worn or damaged and could require replacement during the reassembling phase. Preparing for potential replacements not only streamlines the process but also ensures the system’s longevity once the solenoid valve has been replaced or serviced.

4. REMOVAL PROCEDURE – STEP BY STEP

The removal of the solenoid valve can be approached systematically to prevent mishaps and ensure a clean separation from the solar setup. Initially, verifying that the system is powered down and isolated cannot be overstated. One must confirm the absence of pressure within the lines connected to the solenoid valve by bleeding off any existing pressure.

Next, carefully disconnect any wiring attached to the solenoid valve. Documenting how these wires are configured may be helpful for future reinstallation. Labeling wires helps maintain electrical integrity and ensures that the system can be restored without confusion.

Following the disconnection of electrical components, use appropriate tools to unscrew or unbolt the valve from its position. For threaded connections, a wrench should suffice, while any compression fittings might require a specific socket or improvised tool for loosening. If the valve is soldered or welded in place, careful cutting must be employed, taking care to not damage adjoining pipes or fittings.

During removal, maintaining control of the valve as it is detached is crucial to prevent accidents. It may be helpful to have a second set of hands for stability while unscrewing stubborn connections or when the valve is heavy.

5. INSPECTING THE SOLENOID VALVE ON REMOVAL

Upon successfully detaching the solenoid valve, a thorough inspection is advisable. Assessing the condition of the solenoid valve reveals insights into potential underlying issues within the solar energy system. Common points of concern include corrosion, cracks, and other signs of wear that might indicate a need for replacement.

Moreover, the condition of the seals and gaskets should also be evaluated. Damaged or aged seals can lead to leaks when the valve is reinstalled. Identifying these elements during the removal phase allows for better preventive measures and assures that the next installation will be effective without immediate reoccurrence of the same issues.

6. REINSTALLATION CONSIDERATIONS

Deciding whether to reinstall the same valve or replace it entirely relies on the inspection outcomes. If the valve is in good condition, a clean reinstallation presents a viable option. Follow the reverse order of removal for a systematic reassembly, ensuring all components are aligned and secured properly.

If opting for a new valve, consideration needs to be given to the specifications and compatibility with the existing system. The replacement valve should meet the same pressure and flow rate requirements to ensure seamless operation and efficiency. Ignoring this detail might compromise functionality and lead to future issues.

7. TESTING AND VALIDATION POST-REMOVAL

Once reinstalling the solenoid valve is complete, conducting a thorough testing process is essential. Gradually re-energizing the system will allow for identifying any problems that might arise. Monitoring for leaks, unusual noises, or erratic operation is key during the initial phases of the restart.

Testing should not only involve the solenoid valve itself but also put the entire system through its paces to ensure that all components are functioning harmoniously. Continuing monitoring over the next few days can help ensure longevity and reliability of the installation. Any abnormalities should be addressed immediately, as they can escalate into larger issues if left unchecked.

8. ENSURING LONG-TERM PERFORMANCE

After successfully completing the removal and reinstallation, contemplating long-term maintenance is beneficial. Implementing a regular inspection schedule for the solenoid valve and surrounding components can aid in early detection of wear or malfunction. This proactive approach ensures that performance is optimized and the system operates efficiently.

Equally important is maintaining cleanliness around the valve area. Debris, dirt, and other obstructions can hinder valve operation and possibly lead to failures. Ensuring that all connections and accessible areas are regularly cleaned contributes to the overall performance and lifespan of the solar energy system.

COMMON INQUIRIES

WHAT TOOLS ARE NEEDED FOR SOLENOID VALVE REMOVAL?

To execute the task of removing a solenoid valve, a variety of tools may be necessary. Standard tools typically include adjustable wrenches, pliers, and screwdrivers for loosening and removing screws or bolts securing the valve. Pipe cutters or hacksaws might be required if the connections are welded or soldered. Additionally, a multimeter can assist in verifying power shutdown.

Preparing ahead by gathering these instruments ensures efficiency during the process. Beyond tools, it is advisable to have personal protective equipment, such as gloves and safety goggles, to provide protection during the undertaking. Having everything organized and within reach minimizes interruptions during the project, allowing for a more streamlined operation.

WHAT SAFETY PRECAUTIONS SHOULD BE TAKEN PRIOR TO REMOVAL?

Prior to commencing the removal of a solenoid valve, multiple safety precautions must be observed. First and foremost, deactivating and disconnecting power sources minimizes the risk of electrical shock. Implementing lockout/tagout protocols can provide additional security against unexpected power restoration.

Furthermore, ensuring that there is no residual pressure within the lines is essential. Failure to relieve pressure can result in fluid ejections that could cause injuries or damage to equipment. Wearing suitable protection gear, such as gloves and goggles, also guards against spills or contact with harmful substances. Taking these steps systematically emphasizes responsibility and fosters a safe working environment.

HOW CAN THE CONDITION OF A SOLENOID VALVE BE ASSESSED?

Assessing the condition of a solenoid valve requires a thorough inspection upon removal. A visual examination for signs of wear, corrosion, or structural integrity helps determine whether the valve is functional or needs replacement. Additionally, testing the electrical components can identify signs of malfunction or short circuits.

Particular attention should also be given to the seals and gaskets. Broken or degraded seals may indicate that the valve will not operate efficiently when re-installed. Collectively, these assessments help to ascertain whether the solenoid valve can be reused or if procuring a new replacement is the best course of action.

THE IMPORTANCE OF REGULAR MAINTENANCE CANT BE UNDERESTIMATED. Proper care of solar energy components ensures performance and prevents potential failures. Understanding the workings of a solenoid valve and conducting timely removals, inspections, and reinstallation fosters a healthy operating condition for solar systems. Removing a solenoid valve requires meticulous attention to detail, adherence to safety protocols, and regular maintenance for long-term success. Ensuring a systematic approach minimizes risks and guarantees the system’s overall functional integrity. Regular checks and proactive maintenance pave the way for efficient operation and maximized lifespan.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-remove-the-solenoid-valve-from-solar-energy/