1. To remove the solar tube elbow, gather necessary tools, including a screwdriver and utility knife, then follow a methodical approach to disassemble the connections. 2. Ensure safety precautions are in place, wearing gloves and goggles if necessary. 3. Loosen screws or fasteners securing the elbow section carefully. 4. For any adhesive components, use the utility knife to gently cut away residual material without damaging adjacent tubes. 5. Finally, inspect all connections for leaks after replacement.

REMOVING THE SOLAR TUBE ELBOW

UNDERSTANDING SOLAR TUBE SYSTEMS

Solar tube systems, also known as solar collectors or solar thermal collectors, harness solar energy to heat water or air within residential and commercial buildings. A typical installation includes various components, such as solar tubes, elbows, connectors, and mounting hardware. As with any mechanical system, the integrity of each part is crucial to ensuring optimal energy capture and distribution. Over time, these systems may experience wear, leading to the need for maintenance or replacement of specific components, such as the solar tube elbow.

The elbow serves a pivotal role in directing the flow of heat transfer fluids, and any compromise in its function can impact overall efficiency and efficacy. Factors contributing to the need for removal may include leaks, clogs, or physical damage sustained over time. Therefore, understanding the fundamental composition of solar tube systems is essential when performing maintenance.

Understanding the technical specifications of these systems is vital for technicians, homeowners, or installers. Solar tubes utilize a combination of vacuum insulation and selective surfaces to maximize absorption. An elbow in such a system is not merely a directional component; it plays a role in maintaining pressure and facilitating the smooth flow of heat transfer fluids. Thus, ensuring its integrity is paramount for system longevity and performance.

TOOLS AND PREPARATION

Before embarking on the dismantling process of a solar tube elbow, it is essential to gather the correct tools and materials. These may include a screwdriver set, utility knife, adjustable wrench, safety goggles, and work gloves. The preparatory phase also involves assessing the entire solar tube system to identify any other potential issues. Planning the task ahead can save time and ensure safety, creating a structured approach to the elimination of this component.

Additionally, it is prudent to ensure that the solar system is not under pressure and that the working area is clear of obstacles. Prior to beginning, one must turn off any associated systems, ensuring everything cools down and allowing the individual to handle components without risking burns or inhalation of harmful fumes. When undertaking repairs, consideration of personal protection gear is mandatory. Protective gloves, goggles, and appropriate clothing safeguard against potential injuries.

A correct assessment of the situation might involve examining the elbow for signs of wear or malfunction, such as visible cracks or any signs of leakage. Documenting the current state of the system, such as taking photographs, may also be beneficial for future reference. Engaging in preparation leads to increased confidence and efficiency throughout the removal and installation processes.

STEP-BY-STEP REMOVAL PROCESS

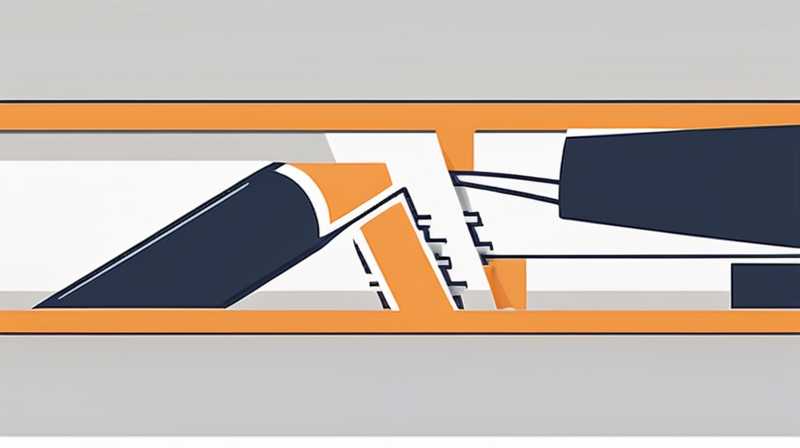

DISCONNECTING THE ELBOW

Once all preparations are complete, initiating the process involves disconnecting the elbow from other components in the solar tube system. This stage typically entails removing any screws or clamp fasteners that hold the elbow in place. As these fasteners are loosed, careful attention must be paid to support adjacent sections to prevent any unintended damage or dislodgment.

In scenarios where adhesive materials secure connections, applying gentle pressure and strategically using a utility knife can help remove residues without harming the adjacent piping. Scraping joints clean is vital for preparation for the new elbow or to repair fittings. If resistance is encountered, re-evaluating and ensuring proper tool application is critical in making the disconnection seamless. Work methodically, tightening or loosening as needed, and always give special attention to any sensitivity around connected tubes.

After successfully removing fasteners and disconnecting the elbow, focus shifts to the assessment of additional components within the system. Ensuring all connections held up during the removal process is key to maintaining the integrity of the system’s overall functionality. Checking for cracks or wear in the remaining pipes can save time in the long run, reducing potential future repairs due to unforeseen damage.

REMOVING THE OLD ELBOW

Once the elbow disconnect is complete, proceed to remove the old component from the assembly. This operation may require additional twisting or pulling, ensuring that the directional alignment of the solar tube remains unimpeded. During this phase, it is essential to remain cautious as tubes often have delicate fittings that may be compromised due to corrosion or aging.

If the elbow remains stubbornly in place, solutions include gentle tapping with a soft tool such as a rubber mallet, which can help in releasing any stuck sections. However, care should be exercised to avoid causing physical damage to the tubing or its fittings during this activity. Any debris or remnants should be thoroughly cleared from the area to ensure a clean installation of the new elbow.

In preparation for the new component’s installation, inspect the adjoining tubes and fittings for any signs of wear or required cleaning. This proactive approach presents an opportunity to diagnose associated issues and rectify them while they are accessible. Additionally, utilize this moment to consider any upgrades or modifications that may enhance the overall efficiency of the solar system. Taking these few additional moments can save significant time and resources later on.

INSTALLATION OF A NEW ELBOW

PREPARE FOR INSTALLATION

Upon successfully removing the old elbow, the next stage involves the installation of a new component. This step must be approached with precision, as the effectiveness of the entire solar tube system hinges on the correct alignment and sealing of each connection. Be sure to prepare the area while observing cleanliness to eliminate contamination from dust, dirt, or moisture.

Prior to installation, examining the new elbow for defects ensures that only parts in optimal condition are introduced into the system. Proper alignment promotes effective flow, and therefore the elbow should be fitted to match the existing directional orientation determined during the removal process. Adjusting the new component into place requires not just fitting it snugly but also ensuring that the surrounding areas are clear of any obstructions that could hinder its functioning.

Consideration must be given to the types of fasteners being utilized; they should align with those used previously to guarantee compatibility. While tightening screws or screws carefully may appear straightforward, it is prudent to monitor the pressure applied to avoid excess stress that could compromise the elbow’s integrity during functionality. Utilizing a torque wrench to ensure consistent fastening can offer predictability in performance.

SECURING THE ELBOW

With adjustment appropriately set, the next priority encompasses securing the elbow into place effectively. This procedure involves a series of checks to ensure that tightness is achieved without over-torquing. Ensuring that all connections have a water-tight or air-tight seal is crucial, as voids can lead to inefficiencies in the energy transfer system, resulting in degraded performance.

As the final elements of the elbow become secured, thorough inspection under a range of conditions helps validate the effectiveness of the installation. Allow adequate time for any adhesive sealants used to cure before pressurizing the lines or connecting the system back to an active state, as this ensures that the integrity of the new installation is maximized.

Restoring the entire solar tube system to its original configuration involves re-integrating all components progressively and with attention to detail. This may involve adjusting neighboring tubes, reconnecting thermal collectors, and testing the flow rates upon completion. Systematically confirming that everything is functioning correctly enables a smooth and efficient operation post-installation.

SYSTEM CHECKS AND TESTING

CONDUCTING FINAL INSPECTIONS

Following the elbow installation, comprehensive checks are paramount to ensure that everything operates as intended. Engaging in a flux test, which involves verifying that heat transfer fluids move freely through the system without obstructions, provides critical insight into the new component’s performance. Review all joints where connections were made ensures there are no visible leaks, which could signify undetected issues.

Additionally, it is essential to monitor temperature differentials across the solar tubing and the associated components to confirm that there is consistent energy transfer. Disruptions or inconsistencies can be indicative of improper fittings or issues elsewhere within the system. Using thermal sensors or temperature probes can offer precise data to substantiate performance.

Paying attention to sounds during operation can also reveal any hidden problems; unusual noises can signify temporary components that may require further adjustment. Keeping a log of temperatures, pressures, and visual inspections after the installation aids in future maintenance planning and serves as a reference for inspecing the system over time.

ROUTINE MAINTENANCE RECOMMENDATIONS

Owning and operating a solar tube system involves recurrent inspections to guarantee longevity and effectiveness post-installation of any component like an elbow. Set reminders to review connections for tightness periodically, as fluctuations in temperature or pressure can alter connector conditions over time. Clear any obstructions, such as debris or vegetation near surface-mounted installations, as these can impede performance.

Establishing a routine that includes cleaning out any sediment in the tanks or pipes annually can keep the system free-flowing. Applying preventative measures can considerably reduce the risk of costly repairs or replacements stemming from neglected components. If future removal of the elbow is necessary, maintaining thorough documentation of previous actions can provide valuable insight.

Acquainting oneself with the manufacturer’s recommendations can offer insights into the lifespan of specific components. This information enables efficient scheduling of replacements based on empirical data while sustaining the overall functionality of the solar tube system.

SOLAR TUBE EFFICIENCY ENHANCEMENTS

CONSIDERING UPGRADES

Post-removal installation periods can serve as prime opportunities for evaluating potential upgrades or enhancements to increase solar tube efficiency. Various component accessories can boost performance – for instance, reflector additions may amplify solar gain by redirecting more sunlight into the tube system, thereby optimizing energy capture.

Furthermore, employing advanced thermal fluids that exhibit superior heat transfer characteristics can enhance the overall system efficiency. When combining these upgraded materials with the recently installed elbow, one can create significant performance improvements that secured connections alone may not achieve.

Additionally, investing in smart monitoring systems that track flow rates or temperatures can provide real-time data, which serves to optimize operating conditions and promptly identify issues. Such systems can alert users to discrepancies that may occur over extended functionalities.

Engaging in these forward-thinking enhancements allows users to consider innovative opportunities alongside maintenance tasks, creating an efficient and sustainable approach to solar water heating and energy conservation.

FREQUENTLY ASKED QUESTIONS

WHAT TOOLS ARE REQUIRED FOR REMOVING A SOLAR TUBE ELBOW?

For effectively removing a solar tube elbow, assembling the right tools is essential. Begin with a screwdriver set that matches the screws securing the elbow. Employing a utility knife is beneficial for cutting through any adhesive materials that might bind components together. Additionally, a wrench or pliers can assist with loosening and holding any nuts or fittings in position, ensuring control during adjustments.

Other helpful tools include safety goggles and work gloves to protect against sharp edges or debris. An adjustable wrench can cater to varying sizes of fasteners, ensuring compatibility across components. Preparing a clean workspace with adequate illumination further aids the process, reducing the risk of accidents and enhancing overall efficiency.

Always prioritize gathering the correct tools ahead of time to ensure a seamless operation. Delays caused by searching for equipment can hinder the overall efficiency of the task at hand, potentially leading to greater frustration or risk of error during the removal process. Optimal preparation fosters a controlled and assured approach to undertaking the elbow removal task.

HOW DO YOU KNOW IF A SOLAR TUBE ELBOW NEEDS REPLACEMENT?

Determining the necessity of replacing a solar tube elbow involves keen observation of various signs associated with performance degradation. When evaluating the elbow, inspect for visible cracks, leaks, or signs of erosion on its surface. If any of these conditions are present, it strongly indicates that the elbow may require immediate replacement to prevent further damage and inefficiencies.

Another critical aspect involves monitoring flow rate and performance metrics. Should heating efficiency noticeably decrease, or if unusual noises occur during operation, inspecting the elbow should be a priority. Regularly checking temperature differentials across connected components can also highlight discrepancies that might signal failure.

Emphasis on routine maintenance checks captures early issues and maintains system integrity. Documenting performance trends can also identify patterns indicating potential elbow or joint deterioration. Ultimately, evaluation relies on both visual inspections and performance data collected over time to determine the necessity of replacement.

WHAT ARE THE BENEFITS OF PROFESSIONAL INSTALLATION OF SOLAR TUBE COMPONENTS?

Engaging professionals for the installation of solar tube components, including elbows, offers numerous benefits. Certified technicians bring specialized knowledge and experience, ensuring high standards of safety and compliance with local regulations. Their ability to navigate complex systems can result in a more streamlined installation process, preventing common pitfalls that inexperienced individuals may encounter.

Additionally, professionals are equipped with advanced tools and techniques that enhance accuracy during the installation phase. They possess insights into the latest products and technologies, which provides an opportunity to recommend upgrades that maximize efficiency. Through systematic testing and validation post-installation, they can ensure that every component functions within optimal parameters.

Furthermore, opting for professional service often comes with warranties or support that safeguard against future issues. This assurance provides peace of mind, ensuring that the investment into solar tube systems yields the most considerable efficiency and longevity possible. Leveraging professional resources cultivates a high-quality, reliable system poised for sustainable function.

**The process of removing and reinstalling a solar tube elbow involves a blend of preparation, execution, and critical evaluation. Proper tools are essential, and undertaking this task requires a systematic approach to ensure all components remain functional. Recognizing when an elbow needs replacement safeguards against decreased performance while enabling the solar tube system to operate at peak efficiency. Regular maintenance checks combined with professional support further augment the longevity of these components, leading to optimized energy capture and performance. Ultimately, a thoughtful approach to both removal and reinstallation, complemented by routine assessments, ensures that solar tube systems continue to thrive, providing valuable energy savings and enhanced temperature control for both residential and commercial applications. The integration of advanced technologies and timely upgrades affords opportunities for improved efficiency, building on the foundation of properly functioning existing components.*

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-remove-the-solar-tube-elbow/