To remove the solar light tube head cover involves a systematic approach that ensures safety and efficiency. 1. Gather necessary tools such as a screwdriver and safety goggles, 2. Identify the mounting screws that secure the cover, 3. Carefully detach the cover without damaging it, 4. Clean any debris from the attachment points before reassembly. It is crucial to avoid forceful removal to prevent damaging the solar light system. For a deeper understanding, one aspect that merits elaboration is the methodical inspection of any electrical components interconnected with the head cover to ensure no wires are inadvertently pulled or damaged during the removal process.

1. UNDERSTANDING SOLAR LIGHT TUBE HEAD COVER FUNCTIONALITY

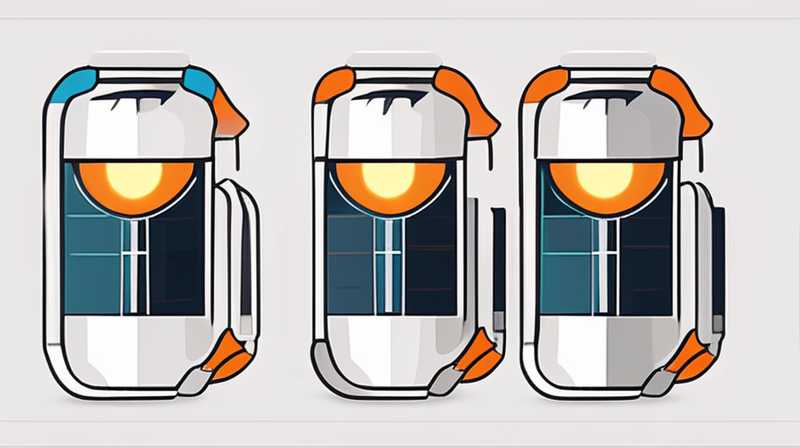

The solar light tube head cover, integral to the system, serves vital purposes, including protection from environmental hazards and shielding ultraprecise components from moisture and dust. Its design ensures optimal performance by allowing light rays to penetrate effectively while containing both solar cells and storage batteries within. A comprehensive understanding of its functionality will enable you to appreciate the importance of correctly handling the cover during maintenance or replacement activities.

The sustainability aspect of these installations cannot be overstated, as they harness renewable energy to illuminate spaces efficiently. Solar light technology often operates independently of traditional electric power sources, which enhances usability in remote locations. The cover contributes to this efficiency by reducing wear and tear from external elements, thus prolonging the overall lifespan of the unit.

2. TOOLS REQUIRED FOR REMOVAL

A well-planned approach for removing the cover minimizes potential mishaps. Essential tools include a Phillips screwdriver, flathead screwdriver, and safety goggles. Each tool plays a specific role, making it necessary to have them ready before starting. For example, the Phillips screwdriver is ideal for accessing screws in tight configurations, while a flathead screwdriver can assist in prying open stubborn closures gently.

In addition to the tools, safety precautions are paramount. Goggles should be worn to shield eyes from debris. Assess the work environment for any hazards, ensuring adequate light and personal protective equipment are present, protecting yourself against potential risks during the removal process.

3. INSPECTING THE HEAD COVER

Before engaging in the removal of the head cover, perform a thorough inspection. This involves checking for any visible signs of damage, wear, or corrosion. Such observations might indicate whether the cover has affected the solar light’s overall functionality or efficiency. Recognizing these issues could help in planning an appropriate maintenance routine.

Moreover, understanding the sealing mechanisms employed in the cover design is essential. In many models, the head cover is adhered with a silicone sealant, making initial removal potentially tricky yet crucial. Familiarizing oneself with these factors establishes a clearer strategy for safe removal, significantly decreasing the risk of damage during procedures.

4. REMOVAL PROCEDURE

Commence the removal process by ensuring all tools are assembled. Begin by turning off the solar light unit to prevent accidental activation. Following this, utilize the screwdriver to gently unscrew the mounting screws, keeping them secured in a designated location to avoid loss.

Once the screws are removed, attempt to lift the head cover carefully. If the cover resists, do not apply excessive force; instead, check if any screws are still attached or if the sealant is adhering it firmly. If the inspection reveals stubbornness, a flathead screwdriver may be utilized with care to gently pry the cover apart.

It’s worth noting that older models may have adhesive securing the cover firmly; thus, employing heat techniques or solvents may assist in loosening the adhesive bond. Heating the adhesive slightly can make it pliable for easier removal. Eventually, ensure to lift the cover away smoothly to prevent any accidental tugging on connected wires.

5. POST-REMOVAL CHECKS

Upon successfully detaching the head cover, conduct a detailed examination of the solar light’s internal components. Assess circuit connections, batteries, and any accumulated debris. These internal inspections help ensure everything functions as intended and allows for immediate maintenance if any parts show signs of distress.

Furthermore, cleaning the compartment is advisable during this phase. Utilizing a dry cloth or canned air can help remove dust and dirt that might have accumulated over time. This cleaning regimen not only enhances the overall efficiency but also extends the lifespan of the solar light by preventing potential blockages that may deter optimal light absorption.

6. REASSEMBLY AND TESTING

Following cleaning and inspection, it’s time to reassemble the solar light unit. Ensure that all components are returned to their original locations accurately, including positioning the head cover correctly. The screws that were removed previously should be reinserted, ensuring they are tightened adequately to facilitate proper security.

After reassembly, conducting tests to confirm that the solar light works efficiently is essential. Observe its brightness and functionality over the subsequent several days to confirm it operates at optimum efficiency. If any malfunction arises during testing, further investigation may be necessary to ascertain if any internal or external components were inadvertently damaged during the procedure.

FREQUENTLY ASKED QUESTIONS

WHAT SHOULD I DO IF THE HEAD COVER IS STUCK AND WON’T COME OFF?

If the head cover is resistant and won’t easily detach, several methods can be employed to tackle this issue effectively. Firstly, ensure you have removed all screws and inspect for hidden fasteners. Sometimes, covers may also have adhesive properties due to sealants applied during installation. If that’s the case, you can carefully introduce some heat, such as from a heat gun or hairdryer, ensuring not to overheat any components. Heat application will soften the adhesive, facilitating gentle removal.

If heat proves ineffective, consider using a flathead screwdriver carefully, ensuring minimal force is applied to avoid damaging the unit. Another alternative is to use solvent like rubbing alcohol or adhesive remover on the junction where the cover meets the base, which can also assist in breaking the bond. Should the issue continue, seeking professional assistance might be warranted to prevent possible damage to your solar light unit.

HOW OFTEN SHOULD I MAINTAIN MY SOLAR LIGHT SYSTEM?

Regular maintenance of a solar light system is crucial to ensure longevity and optimal performance. It is recommended to conduct thorough inspections at least twice a year, ideally at the onset of spring and autumn. During these inspections, check for any accumulated dirt or debris on the solar panel and clean it using a soft cloth. Regular cleaning enhances efficiency by allowing sunlight to penetrate effectively.

Additionally, inspect the head cover and other components for signs of wear or damage. If you reside in an area prone to harsh weather, more frequent checks may be advisable. Address any discovered issues promptly to prevent more extensive damage, enhancing the unit’s durability, efficiency, and ultimately, the safety of its function.

WHAT REPLACEMENT PARTS DO I NEED FOR A SOLAR LIGHT SYSTEM?

When considering replacement parts for a solar light system, several components may need attention over time. Common replacement parts include batteries, solar panels, LED bulbs, and sometimes the head cover itself based on wear and tear. The lifespan of these parts often varies; for instance, batteries should be replaced approximately every two to three years, depending on usage and climate conditions.

Additionally, if the light output diminishes, the LED bulbs may need replacement or reconfiguration. When sourcing replacement parts, it is crucial to identify the specific make and model of your solar light to guarantee compatibility. Always seek high-quality components to ensure the efficient restoration of functionality in your system.

Stepping back to evaluate the removal and replacement of a solar light tube head cover unveils several crucial factors tied to sustainability and efficiency. Proper technique is imperative, ensuring the correct approach throughout the procedure, encompassing the right tools and meticulous inspections. Cleaning and maintaining the components uphold the solar light’s operational integrity, necessitating a consistent review to monitor performance. Experts often advocate early and regular examinations to address wear or other manifestations of harm efficiently. If further assistance is warranted, professional help can deliver enhanced solutions, especially for stubborn issues. Further integration of renewable energy sources into daily life harmonizes with the global pursuit of sustainable energy practices. Understanding how to manage and maintain these systems not only leads to greater personal satisfaction but contributes significantly to environmental well-being.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-remove-the-solar-light-tube-head-cover/