To remove the socket on a solar panel, one must follow a systematic and careful approach. 1. Assess the components of the solar panel system, which involves identifying the type of socket used. 2. Ensure safety precautions are adhered to, including disconnecting power to avoid electric shock. 3. Utilize appropriate tools, such as screwdrivers or pliers, depending on the socket’s design. 4. Execute the removal process with precision, gently unfastening screws or clips to avoid damaging the panel or the wiring.

It’s crucial to elaborate on the assessment of the components since each solar panel may have different connectors and mounting mechanisms that require specific handling techniques and tools for removal. Understanding the manufacturer’s guidelines is also paramount, as this can provide insights into the proper methods and potential hazards involved.

1. ASSESSMENT OF THE SOLAR PANEL COMPONENTS

Understanding the structure of a solar panel is essential before attempting to remove any socket. The components of a solar panel include photovoltaic cells, a protective layer of glass, a frame, and the electrical connections, which include sockets. Each type of socket serves a unique function, whether it’s for connecting cables from the panel to the inverter or linking modules together in series or parallel configurations.

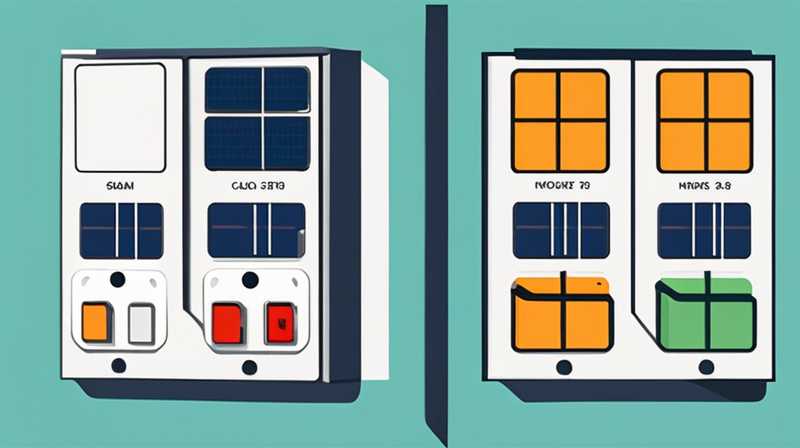

Before engaging with the solar panel, it is necessary to determine the type of connection. Common types include MC4 connectors, JST connectors, and other proprietary connectors which vary by manufacturer. Examining these connectors thoroughly can significantly affect the removal process. For example, MC4 connectors feature a locking mechanism that allows a secure connection but may prove challenging to disengage if unfamiliar with their operation.

Additionally, carefully inspecting the wiring and ensuring no frayed edges or damage will help prevent accidental shorts or further complications. It’s advisable to adhere to detailed documentation or any available installation manuals. Knowledge of the entire system will guide the steps taken in the removal process and minimize the risk of unintended damage.

2. SAFETY PRECAUTIONS

Safety is paramount when working with electrical systems, particularly with solar panels, which can still generate electricity even on cloudy days. The first step involves disconnecting the solar panel from its power source, typically accomplished by employing the system’s disconnect switch or circuit breaker, ensuring that no electrical flow can create risks during the socket removal.

Wear protective gear such as gloves and safety goggles to guard against potential injuries. Isolating the solar panel system ensures that, during socket removal, accidental electrical surges do not pose a threat. Additionally, it may be beneficial to inform others in the vicinity of maintenance work on the system to ensure complete awareness of any hazards present.

One must also be aware of environmental factors such as weather—rain or snow can make working conditions slippery and hazardous. Conducting maintenance during a clear day will enhance safety. A structured safety plan that assesses all risks before initiation cannot be overlooked, serving as a guide throughout the removal process.

3. GATHERING NECESSARY TOOLS

Having the appropriate tools at hand significantly influences the efficiency and success of removing a socket from a solar panel. Common tools used include screwdrivers of various sizes, pliers, multimeters, and socket wrenches, depending on the socket type.

Choosing insulated tools, especially for electrical work, can help prevent electric shocks should any residual energy be present. A multimeter is particularly useful to check for voltage before and after disconnection, ensuring that the component is entirely safe to handle.

Taking the time to organize tools prior to starting the removal process provides convenience and promotes a systematic workflow. Ensuring all tools are functioning well and free of defects promotes efficiency in the task at hand, allowing for a more focused attempt at socket removal without unnecessary interruptions for tool-related issues. Preparedness can significantly affect the performance and outcome of the entire operation.

4. SOCKET REMOVAL PROCESS

Once all the preliminary steps have been taken, and the appropriate tools are gathered, the socket removal process can commence. Begin by ensuring that the workspace is clean and organized, minimizing distractions and creating a safe operating environment.

Carefully inspect the underside of the solar panel where the socket is located. If the socket is secured with screws, use the screwdriver to remove each screw. It may be helpful to place screws in a small container to avoid losing them during the process. In cases where clips or locks secure the socket, gently maneuver the clip or slide to disengage the coupling without excessive force that could damage the panel.

During this phase, maintaining a steady hand and a focused mindset will ensure that the socket is removed efficiently. If any resistance is felt during the removal, stop and reassess the situation rather than applying undue force. Should the socket appear stuck, consider consulting the manufacturer’s guide or reach out to professionals to avoid unnecessary damage.

5. RECONNECTING OR REPLACING THE SOCKET

Once the socket is successfully removed, the next decision revolves around whether to reconnect it or replace it entirely. Assessing the condition of the socket can inform this decision, as a damaged socket may necessitate replacement rather than reconnection.

In situations where replacement is necessary, it’s crucial to select a compatible socket that fits the specifications of the solar panel and its overall system. Review the manufacturer’s guidelines to ensure that the components are matched correctly to avoid efficiency loss or safety hazards.

When ready to reconnect, follow the reverse of the removal process—taking care to securely install the new socket or ensure the previous one has been fixed correctly. Double-checking connections and ensuring all fittings are adequately fastened can enhance the overall effectiveness and longevity of the solar panel system. Patience during this stage ensures that all components function optimally.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE SIGNS THAT A SOCKET NEEDS REPLACEMENT?

Determining whether a socket requires replacement involves careful observation for several telltale signs. Burn marks or discoloration around the socket can indicate overheating or electrical failures, mandating immediate attention. Another significant indicator is physical damage, such as cracks, which may expose internal wiring and create safety hazards.

Additionally, loose connections that lead to intermittent power or complete failure signal the need for a change. Unusual sounds, such as buzzing or clicking from the socket, could also point towards underlying electrical issues, suggesting an inherent risk of malfunction. Regular inspections of solar panel connections can help pinpoint such problems before they lead to more extensive damage.

If you notice any such issues, it is advisable to consult a professional to assess the situation and recommend appropriate replacement measures, as working with electrical components carries significant risk. Being proactive about socket maintenance can prevent future complications and enhance the overall reliability of the solar power system.

HOW DO I ENSURE SAFE HANDLING OF SOLAR PANEL SOCKETS?

Ensuring safety while handling solar panel sockets is of utmost importance given their electrical nature. The first step is to turn off all power to the solar system to eliminate the risk of electric shock. Always verify that the disconnect switch is engaged and check voltage levels using a multimeter before touching any connectors.

Wearing appropriate personal protective equipment (PPE), such as insulated gloves and safety goggles, can provide an additional layer of protection. Adhering to proper techniques when disconnecting sockets, such as pulling on the connectors rather than the wires, will minimize the risk of electrical shorts or damage.

Having a well-lit workspace allows for safer handling and reduces the likelihood of accidents. If unfamiliar with socket types, utilizing manufacturer guidelines can provide insights into safe removal and installation techniques. Conducting regular maintenance and ensuring components are in good condition can also contribute to the overall safety of the solar panel system.

WHAT STEPS SHOULD I TAKE IF I EXPERIENCE SPARKS DURING SOCKET REMOVAL?

Experiencing sparks during socket removal can understandably cause alarm, but knowing the appropriate steps to take can mitigate potential hazards. If sparks occur, immediately stop all work and ensure that the power to the solar system is disconnected. This is vital to prevent further electrical issues and safeguard against shocks.

After ensuring that all components are powered down, inspect the area where the sparks originated to determine the cause. Look for damaged wires, unsecured connections, or signs of short circuits. If unfamiliar with troubleshooting electrical issues, it is highly recommended to contact a professional to assess the system.

Refrain from attempting repairs unless adequately trained, as improper handling can exacerbate the problem. In summary, prompt action, thorough inspection, and seeking professional help can prevent serious damage and enhance safety during solar panel maintenance.

FINAL THOUGHTS

Navigating the process of removing the socket on a solar panel requires not only technical knowledge but also careful attention to safety. Various factors come into play, such as understanding the components, adhering to safety protocols, and utilizing the right tools. Proper assessment of the existing socket is needed to make informed decisions about replacement or reconnection. Furthermore, consistently checking the condition of the solar panel sockets can prevent potential dangers that arise from negligence.

The removal process itself must be approached with precision and patience, confirming that each step progresses methodically without risking personal safety or panel integrity. Whether one is performing routine maintenance or addressing specific issues, having comprehensive information available ensures effective action can be taken to maintain system performance.

In addition, being knowledgeable about how to handle unexpected situations, such as electrical sparks, can contribute greatly to overall safety. Emphasizing the importance of preparedness, understanding safety mechanisms, and conducting thorough checks can facilitate a smoother process in removing solar panel sockets.

Thus, combining theoretical knowledge with practical experience lays the groundwork for effectively managing any challenges posed by solar panel maintenance. This will not only enhance the performance and longevity of solar installations but also contribute to a more sustainable and efficient energy solution.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-remove-the-socket-on-the-solar-panel/