To effectively remove the hand wheel of a solar concealed valve, several steps need to be taken to ensure proper disassembly while preventing any damage to the component. This process can typically be broken down into the following core points: 1. Assessing the valve’s design and functionality, 2. Gathering necessary tools for removal, 3. Carefully detaching the hand wheel, 4. Ensuring safety and maintenance procedures are followed. A thorough understanding of the specific model of the valve in question is essential, as various manufacturers may have unique attachment mechanisms. Additionally, having the right tools on hand – such as wrenches, screwdrivers, and possibly lubricants – will greatly facilitate the removal process. Proceeding with caution helps avoid any potential damage to both the hand wheel and the concealed valve itself.

1. UNDERSTANDING SOLAR CONCEALED VALVES

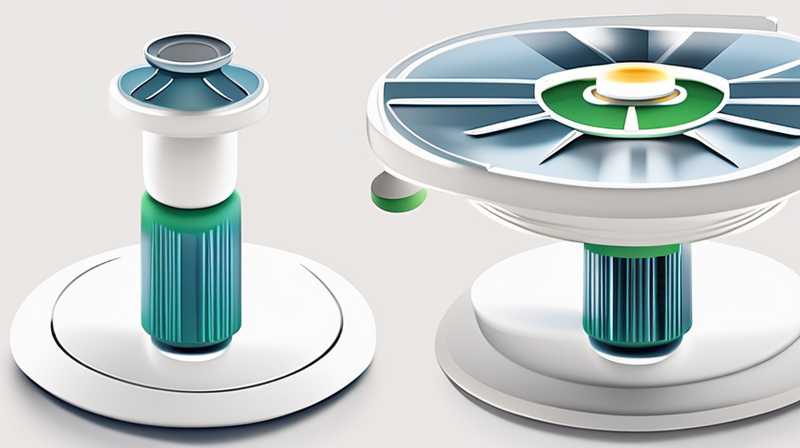

The concept of solar concealed valves pertains to intricate systems designed to manage water flow in solar heating applications. These valves play a pivotal role in regulating the transfer and circulation of heated water, making them critical for the efficiency of solar energy systems. Solar concealed valves are often integrated within the plumbing, making them less visible and more aesthetically pleasing. Their concealed design allows for better installation options and minimizes the risk of accidental tampering or damage, enhancing the longevity of the system.

The functionality of these valves hinges not only on their mechanical components but also on their interaction with the overall plumbing layout of solar systems. Understanding the structure of these valves, including the hand wheel mechanism, is essential before embarking on any maintenance or removal efforts. Typically, the hand wheel is used to adjust settings or manage flow rates, making its accessibility crucial for user operation. Familiarizing oneself with the specific design of the valve in use is the first step toward successful removal and maintenance.

2. GATHERING TOOLS AND PREPARING FOR REMOVAL

Before engaging in the removal of the hand wheel, it is vital to gather the appropriate tools. Commonly required tools may include adjustable wrenches, flathead and Phillips screwdrivers, and lubrication options such as penetrating oil. Each tool serves a specific purpose during the removal process, ensuring that every step is executed smoothly and efficiently.

Preparation also involves identifying the specific type of attachment mechanism that holds the hand wheel in place. Some hand wheels may be secured with setscrews while others might be threaded directly onto the valve shaft. Knowing what type of attachment is in use will help streamline the removal process and avoid unnecessary complications. Once all tools are gathered, and the attachment type is understood, the area around the valve should be cleared of any obstructions to facilitate easy access during disassembly.

3. SAFETY FIRST: PREPARING THE WORKSPACE

Creating a safe workspace is critical when tackling mechanical components. Before attempting to remove the hand wheel of a solar concealed valve, ensure the system is turned off and any residual pressure is adequately released. This preventive measure protects against scalding hot water and reduces the risk of injury associated with sudden pressure releases.

Wearing safety goggles and gloves is recommended to shield the eyes and hands from potential debris and sharp edges during the disassembly process. Ensuring adequate lighting in the working area is also essential, as this will help avoid accidents and ensure that every part of the process can be meticulously examined. A clean and organized workspace allows for a more efficient workflow and minimizes the chances of losing small components during the task.

4. DETACHING THE HAND WHEEL: STEP-BY-STEP

To initiate the removal of the hand wheel, closely observe the specific model’s design to ascertain how it is affixed to the valve. If the hand wheel is secured with screws or bolts, carefully use the appropriate driver to loosen them. Once these fasteners are removed, the hand wheel should become loose and easier to manipulate.

For models using a threaded attachment, gently turn the hand wheel counterclockwise while applying slight upward pressure. Using penetrating oil on stubborn attachments can facilitate the loosening process, making it easier to detach the wheel without exerting excessive force that may damage the valve itself. Throughout this process, continual assessment of the parts being worked on is necessary to ensure that no damage occurs.

5. INSPECTING THE COMPONENTS

Once the hand wheel has been successfully removed, a thorough inspection of both the wheel and the valve should be conducted. Look for signs of wear, corrosion, or damage that could affect performance. Identifying these issues early allows for timely repairs or part replacements, enhancing the overall longevity of the solar heating system.

Cleaning the components can also be beneficial. Using a soft cloth to remove grime can improve mechanical function and prevent misalignment or binding during reassembly. An examination of the valve housing will help confirm that no debris or foreign objects are obstructing the internal mechanisms, which is crucial for optimal performance in any plumbing application.

6. MAINTAINING AND REASSEMBLING THE SYSTEM

After completing any repairs or maintenance, the next step is reassembling the system. Ensure that all components are aligned correctly before securing the hand wheel back onto the valve. Reattach any screws or bolts, following the manufacturer’s specifications for torque settings if available.

Post-reassembly, it’s advisable to operate the valve slowly to ensure everything functions as intended. Monitoring for leaks or irregularities in movement will help establish that the hand wheel has been properly reattached and the valve is operating correctly. If any issues are detected, immediate attention is necessary to prevent further complications.

7. LONG-TERM CARE AND MONITORING

Routine checks should be part of a long-term maintenance approach to solar concealed valves. Regular inspections can help catch any potential issues early on, which can save considerable time and money in repairs. Keeping an eye on the performance of the hand wheel and the valve can help identify wear and tear or deterioration, prompting timely action.

Educational resources and manufacturer guides typically offer detailed recommendations for ongoing care. By adhering to maintenance schedules and best practices, the longevity and efficiency of solar panels and their associated plumbing systems can be maximized. An emphasis on preventive measures is key to sustaining optimal operational efficiency and ensuring that the investment in renewable energy systems is safeguarded.

FREQUENTLY ASKED QUESTIONS

HOW OFTEN SHOULD I INSPECT MY SOLAR CONCEALED VALVE?

Regular inspections are crucial for the longevity and efficiency of your solar concealed valve and the associated systems. It’s generally recommended to conduct inspections at least once a year, but more frequent checks may be warranted depending on system usage, environmental conditions, and manufacturer recommendations. Look for signs of wear, corrosion, or leaks during these checks. If the system operates in harsh weather conditions or experiences significant heat fluctuation, increasing inspection frequency to every six months can be beneficial.

In addition to these scheduled inspections, keep an eye on the operational performance of the valve throughout the season. Unusual sounds, changes in flow rates, or leaks should prompt immediate investigation. Maintaining the valve’s functionality will prevent costly repairs and ensure the longevity of the entire solar heating system. By adopting a proactive approach to maintenance, users can extend the life of their valves and enhance the performance of their solar energy systems.

WHAT TOOLS ARE REQUIRED FOR REMOVING A HAND WHEEL FROM A SOLAR VALVE?

When preparing to remove the hand wheel from a solar concealed valve, specific tools enhance efficiency and effectiveness. Essential tools typically include adjustable wrenches, Phillips and flathead screwdrivers, and lubricating agents such as penetrating oil. Each tool serves a unique purpose, contributing to a smoother disassembly process.

An adjustable wrench is useful for loosening nuts or bolts if the hand wheel is screwed in place. Screwdrivers are needed for any screws that may be securing the hand wheel. Lubricating agents can help unwind stubborn components or reduce friction, making the removal process easier. Utilizing the right tools not only speeds up the disassembly procedure but also minimizes the risk of damage to components. Additionally, having a clean and organized toolbox can help ensure that the removal task proceeds quickly without interruption or confusion.

IS IT NECESSARY TO TURN OFF THE SYSTEM BEFORE REMOVING THE HAND WHEEL?

Yes, it is essential to turn off the entire system before attempting to remove the hand wheel from a solar concealed valve. Doing so serves multiple safety and operational purposes. Disabling the system prevents accidental activation while working and eliminates the risk of injury due to exposure to hot water or pressurized components. Many solar heating systems operate under significant pressure, and even small mistakes can lead to leaks or bursts.

In addition to ensuring safety, shutting down the system allows for a more thorough inspection of the valve mechanism while preventing any interruptions during the maintenance process. Therefore, prior to commencing any disassembly work, it is strongly advised to ensure the system’s power is off and any valves regulating water flow are closed. This practice not only promotes security but also contributes to a more efficient maintenance process.

Careful attention to removing and managing the hand wheel of a solar concealed valve can significantly enhance the efficiency and lifespan of the entire system. Understanding the specific design and functionality of the valve, along with having the right tools and protocols, are instrumental in executing this task effectively. Following a comprehensive maintenance approach, which includes regular inspections, effective repairs, and informed monitoring, is essential for the sustained performance of solar heating systems. The commitment to maintaining these intricate components not only safeguards the investments in renewable energy technology but also aligns with a broader responsibility toward energy efficiency and sustainability. By prioritizing these practices, users can ensure that their systems operate at optimum efficiency while contributing to a greener future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-remove-the-hand-wheel-of-solar-concealed-valve/