1. REMOVE THE GLASS SURFACE SAFELY, 2. USE PROPER TOOLS, 3. FOLLOW STEP-BY-STEP PROCEDURES, 4. HANDLING GLASS WITH CAUTION

Removing the glass surface of a solar street light requires careful attention to detail to ensure safety and efficiency. 1. Ensure safety by wearing protective gear such as gloves and goggles to prevent injuries, 2. Use appropriate tools like screwdrivers, prying tools, and safety glass cutters to facilitate the process, 3. Follow a step-by-step guide to disassemble the light fixture without damaging components, 4. Handle the glass with care to avoid shattering and injury. Disassembling the glass may also vary depending on the manufacturer and model of the solar street light. Therefore, being informed about specific designs can significantly ease the operation.

When dealing with the removal of the glass surface, meticulous planning and execution are vital. This process will be examined in detail throughout this text to provide comprehensive guidance.

1, UNDERSTANDING THE SOLAR STREET LIGHT COMPONENTS

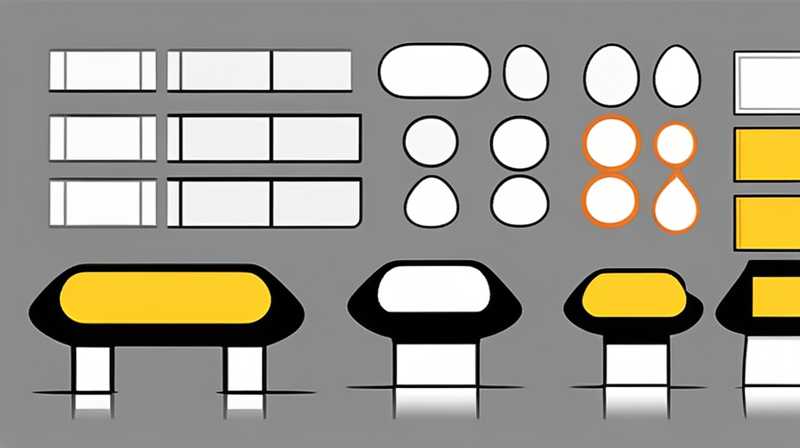

To embark on the journey of removing the glass covering, it is essential to gain familiarity with the components of a solar street light. These fixtures typically have several integral parts that work in concert to harness solar energy efficiently. The primary components include the solar panel, LED lamp, battery, and control circuits. Each of these elements plays a significant role in the overall functioning of the streetlight, and understanding how they are assembled with the glass surface is crucial.

The glass surface often serves multiple purposes: it protects the internal lighting systems from environmental hazards and maximizes light diffusion. This dual role makes it imperative to handle it carefully during any removal process. The glass is usually sealed with adhesives that can vary in composition based on the model and manufacturer, making it important to be aware of the specific construction of the light you are working on.

2, GATHERING THE NECESSARY TOOLS

Before initiating the removal of the glass surface, collecting the correct tools will ensure the task can be accomplished effectively and safely. Essential tools may include screwdrivers (both flathead and Phillips), a utility knife, prying tools, and a heat gun for softening adhesives. Additionally, safety gear such as gloves, goggles, and a dust mask should not be overlooked.

Using the right tools minimizes the risk of damaging the light unit and avoids potential harm to the person performing the task. For example, a heat gun can facilitate the removal of stubborn adhesive by softening it, allowing the glass to detach easily without excessive force. Proper tools are the linchpin of success in such delicate operations.

3, STEP-BY-STEP REMOVAL PROCESS

The removal of the glass surface from a solar street light can be approached methodically to ensure safety and effectiveness. The following steps outline the process in detail while addressing potential pitfalls.

A. PREPARATION PHASE

Start by ensuring that the solar street light is turned off and disconnected from any power source to prevent electrical hazards. Use a utility knife to inspect the seams where the glass surface meets the housing. Carefully run the knife along the edge, identifying any screws or clips that may secure the glass to the frame. This stage is crucial, as rushing or using excessive force can lead to unintended breakage.

Simultaneously, considering the weather conditions is vital. Working in a dry environment will enhance visibility and reduce the likelihood of adhesive softening prematurely due to humidity. Choose a calm day to avoid any interruptions and ensure a smooth working experience.

B. REMOVING SECURING ELEMENTS

Next, focus on the securing elements such as screws, clips, or any adhesive material. Using the appropriate screwdriver, carefully undo any screws without stripping them. Set aside the screws in a designated container to prevent any loss. For clips, gently pry them from their fastening points using a prying tool.

Should adhesive be present, apply the heat gun at a safe distance to soften it. Avoid direct contact with the glass to prevent cracking or shattering. Once the adhesive is sufficiently softened, proceed to carefully lift the glass from its frame. Patience at this stage is paramount, as rushing can lead to excess force being applied, causing the glass to break unexpectedly.

4, HANDLING AND STORING THE GLASS

Once removed, handling the glass surface appropriately is crucial to avoid injuries. Consider utilizing foam or cloth pads on a flat, stable surface during this phase. Gently place the glass down, ensuring it is covered adequately to prevent dust accumulation or accidental impacts.

If the intention is to reuse the glass, proper storage will facilitate this. Store the glass upright, similar to how one would store a picture frame, to reduce stress on any one point and mitigate fracture risks. If the glass is broken or damaged, ensure to dispose of it appropriately in accordance with local regulations for glass waste.

5, ADDRESSING POTENTIAL ISSUES DURING DISASSEMBLY

Even with careful planning, issues may arise during the removal procedure. One common challenge is encountering stubborn adhesives that resist removal efforts. If adhesives prove particularly obstinate, further application of heat may be needed, or using a specialized adhesive remover designed for light fixtures can aid in this endeavor.

Another issue might involve damage to the housing during removal. To avoid this, ensure to work gradually and apply minimal pressure while prying, as excessive force can distort or crack the housing, rendering it unusable. Additionally, should any component become dislodged inadvertently, keep all parts organized to facilitate reassembly later.

6, POST-REMOVAL MAINTENANCE

Once the glass has been removed, it is an excellent opportunity for maintenance on the solar street light components. Inspect the internal wiring, battery condition, and LED functionality to determine any repairs needed before reinstallation. Cleaning the internal surfaces and the LED lens enhances light output and ensures optimal performance once the glass is back in position.

Furthermore, if the glass is undamaged and intended for reinstallation, consider cleaning it with an appropriate cleaning solution that ensures clarity without scratching the surface. Reinstalling clean and undamaged components promotes longevity and efficiency in the lighting system.

7, REASSEMBLY OF THE SOLAR STREET LIGHT

The reversal of the disassembly process needs to be conducted with just as much care and diligence. Position the glass surface back into its rightful place, ensuring it aligns properly with the frame and does not allow for gaps. Reapply any adhesive and ensure that there are no obstructions in the way.

Secure the glass using the original screws or clips, verifying that each component has been correctly fastened without excessive pressure. Completing the reassembly methodically ensures all parts are secure and that the solar light will function correctly once powered.

8, TESTING THE SOLAR STREET LIGHT

After reassembly, conduct a test to verify that the solar street light operates effectively. Ensure that any adjustments necessary based on disassembly have been made, like reconnecting any wires that may have become detached. Observing the light for a period will identify if all functions are restored, including sensor operations, battery charging, and LED brightness.

If the fixture fails to illuminate or functions sporadically, further inspection may be necessary. Identify any missed connections, damaged components, or issues stemming from the initial disassembly to rectify them promptly. The successful testing phase brings about the sense of accomplishment derived from a job well done.

FREQUENTLY ASKED QUESTIONS

HOW OFTEN SHOULD I REMOVE THE GLASS SURFACE OF A SOLAR STREET LIGHT FOR MAINTENANCE?

It is advisable to remove the glass surface for maintenance approximately once or twice a year, depending on environmental conditions. Areas with significant dust, debris, or pollution may necessitate more frequent cleaning. Regular checks help ensure that the solar panels and internal components remain effective and free of damage.

Moreover, keeping an eye on the performance outcomes during regular tests can inform the need for more frequent maintenance. Ideally, the internal systems, such as batteries and LEDs, should also be examined during these up-close inspections. Addressing minor issues early on can enhance the lifespan of the solar street light effectively.

WHAT TYPES OF GLASS ADHESIVES ARE USED IN SOLAR STREET LIGHTS?

The types of adhesives used in solar street lights vary based on the manufacturer and design. Common varieties include silicone sealants, epoxy, and polysulfide-based adhesives. Silicone sealants are popular due to their flexibility, weather resistance, and ease of application. These properties make them ideal for an outdoor application where expansion and contraction due to temperature changes can impact bonding.

Epoxies provide strong adhesion and are often preferred for their structural capabilities. Polysulfide adhesives offer excellent durability in harsh environments and are resistance to weathering. Knowing the general type of adhesive used can inform the best approach to disassembly and reassembly during maintenance.

CAN I REPLACE THE GLASS WITH ANOTHER MATERIAL?

While replacing the glass surface with other materials is theoretically possible, caution is advisable due to various concerns. Choosing alternative materials such as plastic or acrylic may lead to reduced durability compared to glass, as they can scratch easier and deteriorate quicker under sunlight exposure. Glass is preferred in solar lighting applications for its ability to withstand UV rays and extreme temperatures better than alternate options.

Moreover, the functional integrity of the light is at stake, as lenses or protective covers need to allow for maximum light transmittance while protecting internal components. Considering these factors, replacing glass should only be undertaken with materials specifically designed for solar street lights that can provide similar benefits.

The venture of removing the glass surface from a solar street light necessitates a thoughtful approach anchored by preparation, appropriate tools, and meticulous execution. Understanding the components involved, gathering necessary tools, and employing a safe removal process create a successful framework. Post-removal, addressing issues encountered and conducting maintenance bolsters the functionality and longevity of the fixture.

Moreover, being equipped with knowledge about potential challenges, adhesives used, and options for alternatives can significantly simplify the process. Ensuring regular maintenance checks will cultivate an atmosphere of care for these energy-efficient lighting solutions, ultimately preserving their performance and extending their lifespan. The complexity involved may seem daunting, yet with due diligence, the endeavor of disassembling a solar street light can be a manageable and rewarding task.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-remove-the-glass-surface-of-solar-street-light/