To effectively eliminate the float of a solar float valve, one should consider the following elements: 1. Understand the structure of the device, 2. Identify common issues with float mechanisms, 3. Apply appropriate methods for disassembly, 4. Reassess the system after modifications. The float mechanism plays a crucial role in water management, regulating fluid levels in solar applications by ensuring consistent water delivery to the system and preventing overflow. Consequently, it is essential to approach float removal with caution, utilizing the right tools and techniques to maintain the integrity of the overall system while achieving desired results. Focusing on these critical points ensures a comprehensive procedure for successfully addressing float issues within solar float valves.

1. UNDERSTANDING SOLAR FLOAT VALVES AND THEIR IMPORTANCE

Solar float valves function as vital components of solar water systems, diligently regulating water flow to preserve optimal fluid levels within tanks or reservoirs. These devices leverage buoyancy principles, leading to automated functioning that is essential in various solar setups. By understanding the functionality and design of float valves, one can appreciate their pivotal role in preventing system overflow, thereby enhancing efficiency and longevity.

The float itself, typically made from durable plastic or similar materials, rises and falls with the water level. This motion triggers the valve’s opening or shutting action. Float valves are predominantly utilized in agricultural irrigation, livestock watering, and residential solar water heating systems. Recognizing these applications sheds light on why maintaining float functionality is crucial. A malfunctioning float can lead to water wastage, reduced system efficiency, or even damage to the entire solar apparatus.

2. COMMON ISSUES WITH FLOAT MECHANISMS

Despite their robust design, float mechanisms can succumb to various problems over time, necessitating their removal and repair. 1. Sticking Floats: Floats can occasionally become lodged due to debris buildup, mineral deposits, or wear and tear in their pivot points. This sticking can lead to inconsistent water levels and impaired system performance. Identifying the root cause of this issue is paramount for ensuring the longevity and efficiency of the float valve apparatus.

2. Improperly Sized Floats: Another prevalent issue arises when floats are not appropriately sized for their designated valves. Floats that are too large or too small can lead to improper sealing or insufficient monitoring of water levels. Addressing sizing discrepancies may require adjustments or even complete replacements to restore optimal function.

By understanding the potential issues, one can formulate the correct approach to disassembling and removing the float, ultimately leading to appropriate solutions for enhancing system efficiency and reliability.

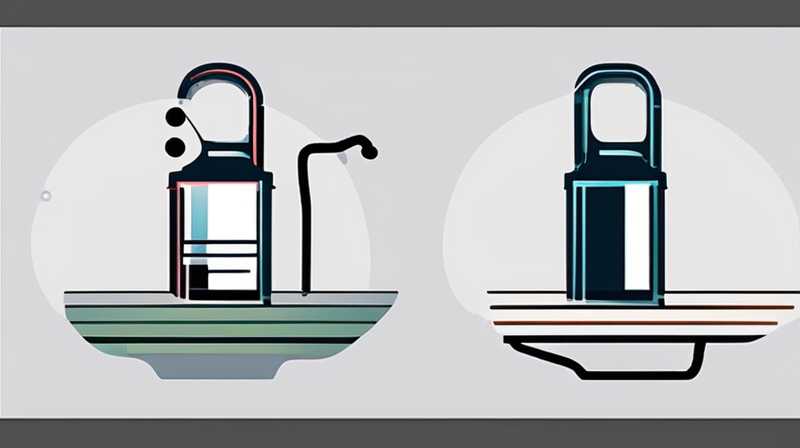

3. DISASSEMBLY PROCEDURE FOR FLOAT VALVES

Embarking on the disassembly process of a solar float valve requires a methodical approach to avoid unnecessary complications. Initially, gathering essential tools is critical. Basic tools might include a screwdriver, pliers, a container for capturing residual water, and cleaning materials. Once the necessary equipment is assembled, the first step involves shutting off the water supply to the valve. This precautionary measure prevents water spillage and maintains a dry working environment.

Subsequently, one should remove the valve from its mounting position. This process may entail unscrewing bolts or unclipping components securing the valve. Care must be taken during this phase to avoid damaging any connected parts. After detaching the valve, it is advisable to thoroughly inspect the float mechanism. This inspection allows for assessing the issues at hand, facilitating informed decisions on how to address them effectively.

4. METHODS TO REMOVE STICKING FLOATS

After identifying a sticking float, various methods can be employed to liberate it from its confined position. One effective technique involves cleaning the float and its pivot point to eliminate any residual debris that may be causing obstruction. A soft brush or cloth can be utilized to gently scrub the surface of the float and its surrounding area.

Additionally, if mineral buildup is present, applying a solution of vinegar or a mild descaling agent can provide significant results. Care must be exercised during this procedure to avoid damaging the float. Once thoroughly cleaned, it is prudent to reassemble the float valve, ensuring smooth operation.

For floats firmly stuck, gentle tapping or manipulating the float may dislodge it. Approaching this process with caution is essential to avoid breaking or cracking the float. Once the float is free, it may require inspection or replacement, depending on its wear and tear.

5. REASSEMBLY AND TESTING OF THE FLOAT VALVE

After addressing any issues with the float, the next phase necessitates thorough reassembly. During this stage, it is imperative to ensure that all components are aligned correctly and securely fastened. Any loose fittings or misalignments can lead to future operational challenges or leaks.

Once the float valve has been reassembled, the next step involves restoring the water supply gradually. Observing the float valve in action allows for immediate detection of any malfunctions or inconsistencies in performance. Testing the valve should include monitoring water levels, ensuring the float rises and falls correctly, and verifying that the valve opens and closes as intended.

Incorporating regular maintenance checks for the float valve can prolong its lifespan. By adopting a proactive approach to inspections and upkeep, system owners can prevent future complications, ensuring consistent performance over time.

6. PREVENTIVE MAINTENANCE STRATEGIES

To minimize the likelihood of float valve issues, implementing a proactive maintenance strategy is vital. 1. Periodic Cleaning: Regularly cleaning the float and valve components can prevent debris buildup and mineral deposits from interfering with functionality. A schedule for inspections should be established, encouraging routine evaluations of the system.

2. Monitoring Water Quality: Maintaining optimal water quality prevents scale and sediment accumulation within the float mechanism. Using water filters, along with regular testing for mineral content, can dramatically improve the flotation process’s effectiveness. By adhering to such preventive measures, one can enhance the durability and efficiency of solar float systems.

In monitoring and maintaining float valves, users cultivate an environment conducive to reliable operational performance. This commitment not only prolongs the life of the float valve but also enhances the overall functionality of the solar water system.

FREQUENTLY ASKED QUESTIONS

WHAT IS A SOLAR FLOAT VALVE AND ITS FUNCTION?

A solar float valve is a device designed to maintain consistent water levels in solar water systems by utilizing a buoyant float mechanism. This valve automatically opens or closes based on the water levels, ensuring efficient operation and preventing overflow. It serves crucial applications in agricultural irrigation, livestock watering, and solar heating systems. The float’s rising and falling motion activates the valve’s mechanism, facilitating seamless and automated water management. Regular maintenance of float valves is necessary for optimal performance, as any malfunction can lead to issues such as water wastage or system inefficiencies.

HOW DO I KNOW IF MY FLOAT VALVE IS MALFUNCTIONING?

Identifying a malfunctioning float valve can be achieved by monitoring water levels within the system. Signs of malfunction may include constant overflow, irregular filling patterns, or the float remaining in a fixed position. Additionally, unusual sounds or leaks can also indicate potential issues. Regular checks on the valve mechanism can assist in detecting such anomalies early on. Performing periodic inspections, cleaning, and attending to any debris that may accumulate can enhance system reliability.

If any issues are identified, immediate action should be taken, either through cleaning or repair, to prevent escalated complications that may compromise overall performance.

CAN FLOAT VALVES BE REPAIRED OR DO THEY NEED TO BE REPLACED?

In many instances, float valves can be effectively repaired rather than replaced. Common issues, such as sticking floats or debris blockage, can typically be resolved through cleaning and appropriate adjustments. However, in cases where the float mechanism is significantly damaged (for instance, cracks or breaches that compromise buoyancy), replacement may be necessary. Assessing the float for wear and tear is critical prior to dismissing the entire valve.

Conducting regular maintenance extends the lifespan of the float valve, encouraging successful repairs when required. Ultimately, this approach fosters more sustainable solar system management and operational efficiency.

FINAL THOUGHTS ON FLOAT VALVE MAINTENANCE

Removing the float of a solar float valve requires understanding, patience, and attention to detail. Proper knowledge of its functionality and common issues guides users in performing necessary maintenance tasks, mitigating the potential for future complications. By following established procedures for disassembly, addressing sticking floats, and promoting preventive maintenance practices, one can successfully ensure that solar float valves operate efficiently over extended periods.

Incorporating regular inspections and cleaning routines can prevent debris accumulation, enhancing the float’s operational capability. However, recognizing when repair is insufficient and replacement is essential maintains the overall effectiveness of the solar system. By fostering an ongoing relationship with maintenance and care, users contribute to optimal performance and longevity of float valves, ultimately yielding sustainable benefits for their solar applications.

Emphasizing the importance of regular upkeep and proactive measures can establish a more reliable and efficient solar water system. This commitment not only enhances energy conservation but also contributes to water management in broader agricultural and ecological contexts. By thoughtfully engaging with float valve maintenance, one can navigate the complexities of solar systems with ease and efficacy.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-remove-the-float-of-solar-float-valve/